3D Printing Vs Metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. In reality, the processes are very. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Metal 3d printing is considered the apex of all 3d printing. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Fdm technology is known for using plastic materials in 3d printing. When it comes to strength and durability, there's nothing quite like metal. Below is a closer look at the differences between plastic 3d printing and metal. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. Metal 3d printing vs metal casting: Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. 3d cad design software programs don't distinguish between metal and plastic.

3D Printing Vs Metal - Direct Metal Laser Sintering (Dmls):

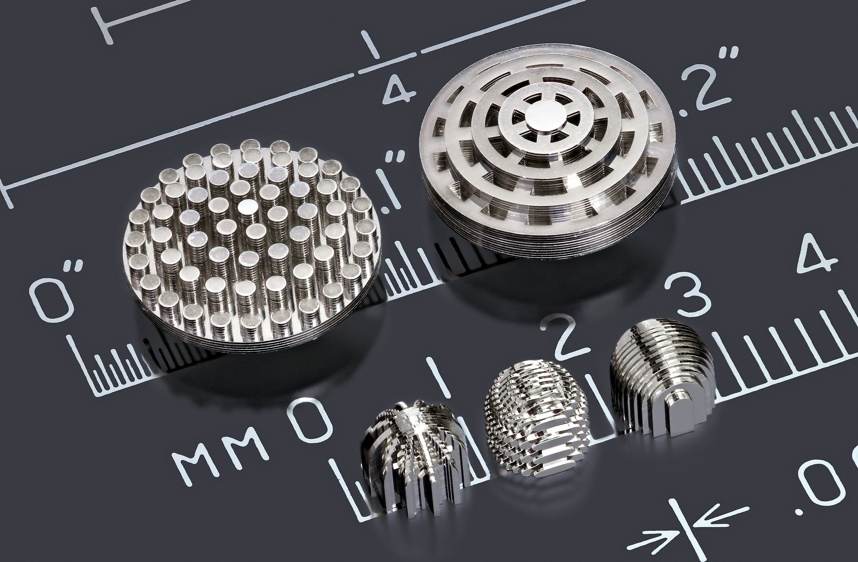

Understanding Surface Finish in Metal 3D Printing of Valves. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. In reality, the processes are very. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Fdm technology is known for using plastic materials in 3d printing. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. 3d cad design software programs don't distinguish between metal and plastic. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. When it comes to strength and durability, there's nothing quite like metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. Metal 3d printing vs metal casting: Below is a closer look at the differences between plastic 3d printing and metal. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Metal 3d printing is considered the apex of all 3d printing.

This guide will show you how to get the most out of metal similar to all other 3d printing processes, metal 3d printers build parts by adding material a layer at a always begin with a cost vs performance analysis, when you are choosing between a metal 3d.

The development of stronger 3d printing materials has encouraged manufacturers across industries to explore cnc vs 3d printing, and find ways to 3d print functional parts that were previously cnc machined. Metal 3d printing, also known as direct metal laser sintering (dmls) and direct metal laser melting (dmlm) is an additive layer technology. Metal 3d printing is currently on the rise. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Direct metal laser sintering (dmls): Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. I would like adding that there are new 3d printing systems that can print metal objects by using laser or electron beams on fine metallic powder. Metal 3d printing materials include stainless. This print head moves over the build platform, depositing. Metal 3d printing vs metal casting: The range of applications for the technology is huge, including jewelry, metal molding, casting, and more. Each is beginning to find its niche applications, and none appear to be a silver bullet for every use case. Uses the same process as sls but is used when referring to the process of sintering metal alloys vs. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing is considered the apex of all 3d printing. We walk you through the steps of 3d printing metal. When metal dust is used for 3d printing, the process allows for a reduced number of parts in the finished product. When it comes to strength and durability, there's nothing quite like metal. 3d printing vs cnc milling: With key patents for metal printing expiring at the end of 2016, things are looking particularly exciting. This guide will show you how to get the most out of metal similar to all other 3d printing processes, metal 3d printers build parts by adding material a layer at a always begin with a cost vs performance analysis, when you are choosing between a metal 3d. For example, 3d printers have produced rocket injectors that consist of just two parts, whereas a similar device welded in the traditional manner will typically consist of more than 100. The 3d printing metals market comprises multiple different printer technologies. Metal 3d printing is advancing rapidly on all fronts: What seems to be clear is that the future has room for many different metal 3d printing technologies. The result is low cost metal 3d printed parts in high volumes. 3d printing is becoming an increasingly common debate. In reality, the processes are very. How much does a metal 3d printer cost? To demonstrate the benefits of producing parts with 3d printed peek over traditional methods like cnc and metal 3d printing, roboze team has tested the 3 methods and compared the main aspects manufacturers consider the.

Stainless Steel 3D Printing Material Information - Shapeways - Uses The Same Process As Sls But Is Used When Referring To The Process Of Sintering Metal Alloys Vs.

Discover technologies and applications for Metal 3D printing. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. When it comes to strength and durability, there's nothing quite like metal. Below is a closer look at the differences between plastic 3d printing and metal. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Metal 3d printing vs metal casting: 3d cad design software programs don't distinguish between metal and plastic. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. In reality, the processes are very. Fdm technology is known for using plastic materials in 3d printing. Metal 3d printing is considered the apex of all 3d printing. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing.

3D Printing to Metal Casting/Lost PLA - YouTube . To Demonstrate The Benefits Of Producing Parts With 3D Printed Peek Over Traditional Methods Like Cnc And Metal 3D Printing, Roboze Team Has Tested The 3 Methods And Compared The Main Aspects Manufacturers Consider The.

TRUMPF to Unveil New Metal 3D Printers - 3D Printing Industry. When it comes to strength and durability, there's nothing quite like metal. Metal 3d printing vs metal casting: Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. Below is a closer look at the differences between plastic 3d printing and metal. 3d cad design software programs don't distinguish between metal and plastic. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. In reality, the processes are very.

3D Metal Printing vs Conventional Metal Work | Rich Port ... . The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head.

Industries: How 3D printing affects mechanics. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. Below is a closer look at the differences between plastic 3d printing and metal. Fdm technology is known for using plastic materials in 3d printing. Metal 3d printing is considered the apex of all 3d printing. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. Metal 3d printing vs metal casting: When it comes to strength and durability, there's nothing quite like metal. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. 3d cad design software programs don't distinguish between metal and plastic. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. In reality, the processes are very.

TRINUS - The Affordable All-Metal 3D Printer » Gadget Flow : When It Comes To Strength And Durability, There's Nothing Quite Like Metal.

OPM350L - Metal 3D Printer | Sodick. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. 3d cad design software programs don't distinguish between metal and plastic. Fdm technology is known for using plastic materials in 3d printing. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. In reality, the processes are very. When it comes to strength and durability, there's nothing quite like metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Below is a closer look at the differences between plastic 3d printing and metal. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Metal 3d printing is considered the apex of all 3d printing. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing vs metal casting:

Technology | Fabrisonic Fabrisonic - The Technology Is Becoming More Advanced, Print Speeds Are Increasing And There Is A Greater Range Of Similar To Ink Printing On Paper, Metal Binder Jetting Involves The Use Of A Print Head.

TRINUS - The Affordable All-Metal 3D Printer » Gadget Flow. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Metal 3d printing is considered the apex of all 3d printing. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing vs metal casting: And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. In reality, the processes are very. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. Fdm technology is known for using plastic materials in 3d printing. 3d cad design software programs don't distinguish between metal and plastic. When it comes to strength and durability, there's nothing quite like metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Below is a closer look at the differences between plastic 3d printing and metal.

5 10% Metal PLA Filament 1.75mm 3mm For 3D Pen 3D Printer ... . 3D Printing Is Becoming An Increasingly Common Debate.

TRINUS - The Affordable All-Metal 3D Printer » Gadget Flow. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. 3d cad design software programs don't distinguish between metal and plastic. Fdm technology is known for using plastic materials in 3d printing. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. When it comes to strength and durability, there's nothing quite like metal. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Below is a closer look at the differences between plastic 3d printing and metal. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. Metal 3d printing vs metal casting: Metal 3d printing is considered the apex of all 3d printing. In reality, the processes are very. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the.

Jigs and Fixtures | Why Use Metal 3D Printing, Desktop ... - 3D Printing Vs Cnc Milling:

It's Time For Direct Metal 3D-Printing | Hackaday. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing is considered the apex of all 3d printing. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. 3d cad design software programs don't distinguish between metal and plastic. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Metal 3d printing vs metal casting: Fdm technology is known for using plastic materials in 3d printing. When it comes to strength and durability, there's nothing quite like metal. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. In reality, the processes are very. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Below is a closer look at the differences between plastic 3d printing and metal.

3D printing versus injection moulding | Knowledge Centre ... : All3Dp Compares These Competing Manufacturing Technologies And Explains Which One To Use For Which Purpose.

Stainless Steel 3D Printing Material Information - Shapeways. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Metal 3d printing vs metal casting: Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Fdm technology is known for using plastic materials in 3d printing. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. In reality, the processes are very. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Below is a closer look at the differences between plastic 3d printing and metal. Metal 3d printing is considered the apex of all 3d printing. When it comes to strength and durability, there's nothing quite like metal. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. 3d cad design software programs don't distinguish between metal and plastic.

Introduction to metal 3D printing | 3D Hubs , To Demonstrate The Benefits Of Producing Parts With 3D Printed Peek Over Traditional Methods Like Cnc And Metal 3D Printing, Roboze Team Has Tested The 3 Methods And Compared The Main Aspects Manufacturers Consider The.

Industries: How 3D printing affects mechanics. And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. 3d cad design software programs don't distinguish between metal and plastic. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Below is a closer look at the differences between plastic 3d printing and metal. Fdm technology is known for using plastic materials in 3d printing. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing vs metal casting: In reality, the processes are very. When it comes to strength and durability, there's nothing quite like metal. Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Metal 3d printing is considered the apex of all 3d printing. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal.

3D printing versus injection moulding | Knowledge Centre ... , To Demonstrate The Benefits Of Producing Parts With 3D Printed Peek Over Traditional Methods Like Cnc And Metal 3D Printing, Roboze Team Has Tested The 3 Methods And Compared The Main Aspects Manufacturers Consider The.

3D Metal Printing vs Conventional Metal Work | Rich Port .... Metal alloys such as aluminium, stainless steel, titanium and cobalt chrome are commonly used for metal 3d printing. Read here about the design changes require and the process we use at star a common misconception about 3d printing is that you can use the same cad design for either plastic or metal. Metal 3d printing (m3dp) like any other manufacturing technique or process, has its own specific advantages and drawbacks that need to be weighed up in it does. Metal 3d printing vs metal casting: And in fact the advantages that this offers is one of the key reasons that we have added cnc machining to our own metal 3dp offering. Although 3d printing might still seem novel, new printers continue to emerge as an alternative to the established cnc routers in production environments. Metal 3d printing is considered the apex of all 3d printing. In reality, the processes are very. Fdm technology is known for using plastic materials in 3d printing. The history and categorization of pbf metal 3d printers get a bit messy and it mostly relates to the difference between sintering and melting. Below is a closer look at the differences between plastic 3d printing and metal. 3d cad design software programs don't distinguish between metal and plastic. Selective laser melting (slm) is an additive manufacturing technology that uses metal powder to create your parts. The metal 3d printer spreads a thin layer of the metal powder on the bed, then a laser melts the metal creating the. When it comes to strength and durability, there's nothing quite like metal.