3D Printing Types Of Infill. The infill the amount of material that occupies the internal part of the piece. Nine common styles of infill source: These can include items with moving parts, clips, and hooks, drone bodies, or anything. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. There is too much superficial knowledge. Amongst the ten standard types. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use.

3D Printing Types Of Infill - With The Release Of Their Public Beta Of Cura Type A, The Infill For A 3D Printed Part Is Also 3D.

What infill should you use for your 3D prints? - X3D .... Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill the amount of material that occupies the internal part of the piece. Nine common styles of infill source: Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! There is too much superficial knowledge. Infill percentage in 3d printing. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. These can include items with moving parts, clips, and hooks, drone bodies, or anything.

Best infill for strength vs material used.

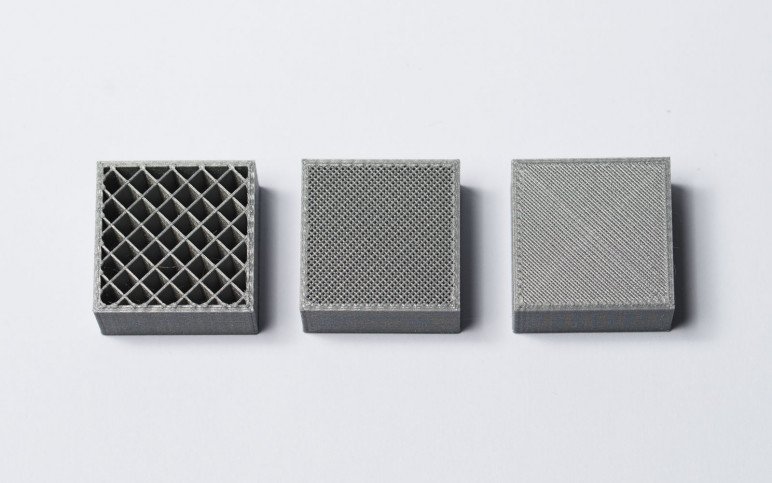

The infill print speed therefore can be reduced to reduce print time since this area is not visible. Basically the final 3d printed model will have different infill densities depending on the region of the model. What is the typical infill amount you use when 3d printing objects? Best infill for strength vs material used. Infill patterns can be used to reduce material usage and printing time. Various infill patterns are available in the 3d the mechanical strength of printed parts is influence by different infill patterns. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Type a machines just changed all of this. Moreover, this type of 3d printing filament is not biodegradable, but it is recyclable. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Amongst the ten standard types. Hunter626103d printers 3d printing 3d printers. The infill in 3d printing can be carried out with the following types: When modelling for 3d printing, can i distinguish somehow the type of infill in various areas of the model? This type of infill prints relatively quickly because the printhead mostly travels in straight lines across the part. These can include items with moving parts, clips, and hooks, drone bodies, or anything. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Shell and infill properties impact the performance and cost of fdm 3d printing. Download files and build them with your 3d printer, laser cutter, or cnc. However, each 3d printing material has unique material properties and these become increasingly important when attempting to combine two different types of filaments. Say there may be some areas in the model using tinkercad.com only so far. Places where 100% infill is wanted are usually walls of the case and threads for the bolts but i want to make the. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. By setting the infill percentage a structure is generated inside sealed of parts of the model that contains a lot less material while maintaining most of its strength. The part of the print that is exposed to the outside of the model, facing the build plate. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. It can be difficult to explain important 3d printing concepts like infill percentage, shells, resolution, and the need for supports, smith explains. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. The main challenge of 3d printing is to reproduce the complex microarchitecture of ecm with different cell types in sufficient resolution to biological functional recapitulation to mimic the biological living tissues. Infill percentage in 3d printing. The term 3d printing can refer to a variety of processes in which.

Infill and Strength: Functional Design Doesn't Stop at the ... : There Is Too Much Superficial Knowledge.

CURA 2.6: Different infills in the same print - IdeaTo3D. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. There is too much superficial knowledge. Infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Amongst the ten standard types. Nine common styles of infill source: I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. These can include items with moving parts, clips, and hooks, drone bodies, or anything. The infill the amount of material that occupies the internal part of the piece. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Infill provides the 3d print with internal support as the printer builds each layer.

Infill and Strength: Functional Design Doesn't Stop at the ... , This Type Of Infill Prints Relatively Quickly Because The Printhead Mostly Travels In Straight Lines Across The Part.

My Adventures with 3D Printed Insoles - Part 2/4 - Gyrobot .... Amongst the ten standard types. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Nine common styles of infill source:

What is the influence of an infill pattern in 3D printing ... , This type of infill prints relatively quickly because the printhead mostly travels in straight lines across the part.

3D Printing Infill: The Basics - Simply Explained | All3DP. Infill provides the 3d print with internal support as the printer builds each layer. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. These can include items with moving parts, clips, and hooks, drone bodies, or anything. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. There is too much superficial knowledge. Infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Amongst the ten standard types. Nine common styles of infill source: Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! The infill the amount of material that occupies the internal part of the piece. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use.

What Is The Strongest Infill Pattern For 3D Printing ... - This Shape Is The Most Efficient Infill And Fastest To Print, The Goto Infill For Most Things.

What is the influence of infill %, layer height and infill .... Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Infill provides the 3d print with internal support as the printer builds each layer. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The infill the amount of material that occupies the internal part of the piece. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. These can include items with moving parts, clips, and hooks, drone bodies, or anything. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Nine common styles of infill source: There is too much superficial knowledge. Infill percentage in 3d printing. Amongst the ten standard types. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used.

3D Druck Infill Guide Grundlagen, Muster und Stabilität : Each Vary In The Way They Form Plastic And.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. These can include items with moving parts, clips, and hooks, drone bodies, or anything. Nine common styles of infill source: Infill percentage in 3d printing. There is too much superficial knowledge. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Infill provides the 3d print with internal support as the printer builds each layer. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. The infill the amount of material that occupies the internal part of the piece. Amongst the ten standard types. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts!

3DMatter Researches Effects of Infill Percentages ... . Without It, Prints Wouldn't Have Much Structure Or Stability, Making Them Incredibly Fragile.

SEM images of 3D printed CHA scaffolds at different infill .... There is too much superficial knowledge. These can include items with moving parts, clips, and hooks, drone bodies, or anything. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Infill percentage in 3d printing. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Amongst the ten standard types. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. Nine common styles of infill source: Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! The infill the amount of material that occupies the internal part of the piece. Without it, prints wouldn't have much structure or stability, making them incredibly fragile.

What is the influence of infill %, layer height and infill ... . If You Want To Learn The It Does Not Degrade To A Color In Multiple Layers Of Applied Thickness.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! The infill the amount of material that occupies the internal part of the piece. These can include items with moving parts, clips, and hooks, drone bodies, or anything. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Infill percentage in 3d printing. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Amongst the ten standard types. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. There is too much superficial knowledge. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Nine common styles of infill source:

TESTING 3D printed INFILL PATTERNS for their STRENGTH ... , The Main Challenge Of 3D Printing Is To Reproduce The Complex Microarchitecture Of Ecm With Different Cell Types In Sufficient Resolution To Biological Functional Recapitulation To Mimic The Biological Living Tissues.

What's the Best Cura Infill Pattern for You Needs? | All3DP. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Amongst the ten standard types. The infill the amount of material that occupies the internal part of the piece. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Nine common styles of infill source: Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Infill provides the 3d print with internal support as the printer builds each layer. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! There is too much superficial knowledge. These can include items with moving parts, clips, and hooks, drone bodies, or anything. Infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

My Adventures with 3D Printed Insoles - Part 2/4 - Gyrobot ... . It Can Be Difficult To Explain Important 3D Printing Concepts Like Infill Percentage, Shells, Resolution, And The Need For Supports, Smith Explains.

3D Printing Infill: The Basics - Simply Explained | All3DP. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. These can include items with moving parts, clips, and hooks, drone bodies, or anything. The infill the amount of material that occupies the internal part of the piece. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Infill percentage in 3d printing. Nine common styles of infill source: There is too much superficial knowledge.

Software Catchup: Type A Machine's Radical 3D Print Infill , It Will Save You Material Much Of 3D Printing Is Really Structure And Design And I Feel That Having Some Knowledge In Why Nature Does What It Does Will Add Some Forethought To.

Ultimaker Cura infill settings. Without it, prints wouldn't have much structure or stability, making them incredibly fragile. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Normally, rolling programs allow the percentage with such a low percentage, the long printing times of complex figures or objects that do not need resistance to any type of stress are reduced. Nine common styles of infill source: Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. These can include items with moving parts, clips, and hooks, drone bodies, or anything. There is too much superficial knowledge. I tested the effect of infill pattern, infill density and shell thickness on the strength of 3d printed parts! Without infill, printing the top layers would be very difficult , as the these types of models are prints that will see heavy or functional use. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece.