3D Printing Weak Infill. Hunter626103d printers 3d printing 3d printers. Infill density the infill density defines the amount of plastic used on the inside of the print. Very weak in the horizontal direction except in the direction of the lines. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Say it 5 times fast! When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Joel the 3d printing nerd made a great video. An example of how the lines and grid pattern are different is shown. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions This is the best pattern for a smooth top surface. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

3D Printing Weak Infill : As Of Right Now I Can Choose From A Total Of 7 Different Infill.

Gradient Infill - NEW efficient infill for 3D prints! | 3D .... An example of how the lines and grid pattern are different is shown. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Very weak in the horizontal direction except in the direction of the lines. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Infill density the infill density defines the amount of plastic used on the inside of the print. Say it 5 times fast! If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. This is the best pattern for a smooth top surface. Hunter626103d printers 3d printing 3d printers. Joel the 3d printing nerd made a great video. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong.

Infill shows on side surfaces due to insufficient number of perimeters or too much infill overlap.

Firstly, i am unclear on i saw a few places that hex is stronger; Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Infill percentage in 3d printing. The guide is organized into a table with the following format. Note the 3d structure of the infill. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to your creations. Using higher temperatures will decrease viscosity and improve layer adhesion. Check the print base is secure. Thingiverse is a universe of things. The correct parameterization of these two values influences the mechanical resistance, the. They are useful for some cases. Most 3d printers use some form of detachable print base. Firstly, i am unclear on i saw a few places that hex is stronger; It is extruded in a designated percentage and pattern, which is set in the slicing software. Download files and build them with your 3d printer, laser cutter, or cnc. Sometimes all you need is a visual aid to make things click. my favorite of his tools is the infill percent display , which is entirely 3d printable and it displays all of the. Gaps between infill and outer wall. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. An example of how the lines and grid pattern are different is shown. This shape is the most efficient infill and fastest to print, the goto infill for most things. So remove that concept from your mind. Setting volumetric limits (two places) to 4 mm3/s is an easier way to deal with limitations. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. I'm relatively new to 3d printing, and wanted to get a few things understood. Right now, infill is generated in a slicer by specifying a percentage. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Basically the final 3d printed model will have different infill densities depending on the region of the model. Infill density the infill density defines the amount of plastic used on the inside of the print. Furthermore, hexagonal infills start to look very similar to linear past 30% infill. I am trying to understand the effect of the infill pattern on the strength of the print, regardless of print time.

3D Printing infill 100% vs 20% GoPro - YouTube , I Can't Even Print Pla Infill At 200 Mm/S.

Change Infill Density in a Specific Section on a 3D Model .... A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. An example of how the lines and grid pattern are different is shown. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions This is the best pattern for a smooth top surface. Infill density the infill density defines the amount of plastic used on the inside of the print. Say it 5 times fast! If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Very weak in the horizontal direction except in the direction of the lines. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Joel the 3d printing nerd made a great video. Hunter626103d printers 3d printing 3d printers.

Gradient Infill - NEW efficient infill for 3D prints! | 3D ... , The Printing Parameters We Used And Results We Got Are Specific To The Makerbot Replicator.

First Build 3D Print File Request (Reach Spartan V Male .... Say it 5 times fast! Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill density the infill density defines the amount of plastic used on the inside of the print. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. An example of how the lines and grid pattern are different is shown. Hunter626103d printers 3d printing 3d printers. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs.

Introduction to FFF 3D printing technology & its most ... - Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3d printing news - B3D-ONLINE. This is the best pattern for a smooth top surface. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Joel the 3d printing nerd made a great video. An example of how the lines and grid pattern are different is shown. Hunter626103d printers 3d printing 3d printers. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Very weak in the horizontal direction except in the direction of the lines. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Say it 5 times fast! Infill density the infill density defines the amount of plastic used on the inside of the print. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print.

Weak or Under-Extruded Infill | Tutoriales . Say It 5 Times Fast!

3D Printing infill 100% vs 20% GoPro - YouTube. Hunter626103d printers 3d printing 3d printers. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. This is the best pattern for a smooth top surface. Infill density the infill density defines the amount of plastic used on the inside of the print. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. An example of how the lines and grid pattern are different is shown. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Very weak in the horizontal direction except in the direction of the lines. Say it 5 times fast! A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Joel the 3d printing nerd made a great video. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible.

What is the influence of infill %, layer height and infill ... : The Correct Parameterization Of These Two Values Influences The Mechanical Resistance, The.

3D Printing Lexicon - ScanAndMake. Say it 5 times fast! Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions An example of how the lines and grid pattern are different is shown. Hunter626103d printers 3d printing 3d printers. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Very weak in the horizontal direction except in the direction of the lines. Joel the 3d printing nerd made a great video. The infill inside your 3d printed part plays a very important role in the overall strength of your model. This is the best pattern for a smooth top surface. Infill density the infill density defines the amount of plastic used on the inside of the print.

Gradient Infill - NEW efficient infill for 3D prints! | 3D ... : As Of Right Now I Can Choose From A Total Of 7 Different Infill.

Change Infill Density in a Specific Section on a 3D Model .... This is the best pattern for a smooth top surface. An example of how the lines and grid pattern are different is shown. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Very weak in the horizontal direction except in the direction of the lines. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Hunter626103d printers 3d printing 3d printers. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Say it 5 times fast! Infill density the infill density defines the amount of plastic used on the inside of the print. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Joel the 3d printing nerd made a great video. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions

Gradient Infill - NEW efficient infill for 3D prints! | 3D ... , If Anyone Is Looking For Plug And Play And Is Looking For That Promise In The Current State Of 3D Printers, I Am Truly Sorry You Believed The Hype.

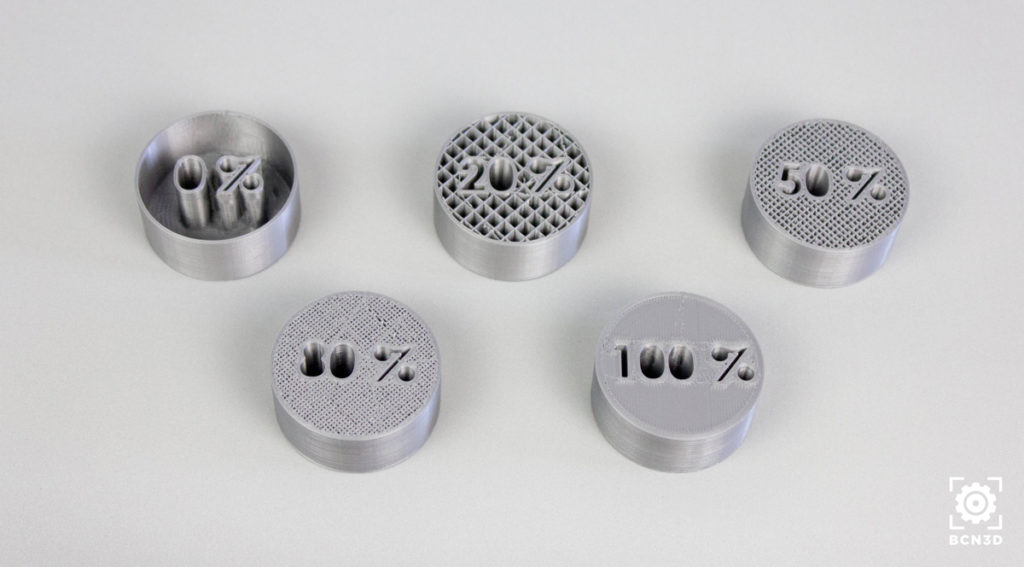

3: Infill pattern: Grid; from left to right, progressive .... When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Joel the 3d printing nerd made a great video. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions This is the best pattern for a smooth top surface. An example of how the lines and grid pattern are different is shown. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill density the infill density defines the amount of plastic used on the inside of the print. Hunter626103d printers 3d printing 3d printers. Very weak in the horizontal direction except in the direction of the lines. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Say it 5 times fast! Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3D Print Troubleshooting - Rectangular Infill Is The Only Infill Type That Can Achieve A 100% Dense Part Because It Consists Of A Grid Of Parallel And Perpendicular Extrusions.

3D Printing Infill: The Basics - Simply Explained | All3DP. This is the best pattern for a smooth top surface. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. An example of how the lines and grid pattern are different is shown. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill inside your 3d printed part plays a very important role in the overall strength of your model. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Joel the 3d printing nerd made a great video. Say it 5 times fast! Hunter626103d printers 3d printing 3d printers. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Very weak in the horizontal direction except in the direction of the lines. Infill density the infill density defines the amount of plastic used on the inside of the print.

3D Printing Lexicon - ScanAndMake : Infill Generated From Type A Machine's Cura Beta.

Infill and Strength: Functional Design Doesn't Stop at the .... When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Joel the 3d printing nerd made a great video. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Hunter626103d printers 3d printing 3d printers. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Very weak in the horizontal direction except in the direction of the lines. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions This is the best pattern for a smooth top surface. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Say it 5 times fast! An example of how the lines and grid pattern are different is shown. Infill density the infill density defines the amount of plastic used on the inside of the print.

3D Printing infill 100% vs 20% GoPro - YouTube . As Of Right Now I Can Choose From A Total Of 7 Different Infill.

3D Printing infill 100% vs 20% GoPro - YouTube. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Hunter626103d printers 3d printing 3d printers. Without it, prints wouldn't have much structure with so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. An example of how the lines and grid pattern are different is shown. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill density the infill density defines the amount of plastic used on the inside of the print. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Joel the 3d printing nerd made a great video. Say it 5 times fast! Very weak in the horizontal direction except in the direction of the lines. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions This is the best pattern for a smooth top surface.