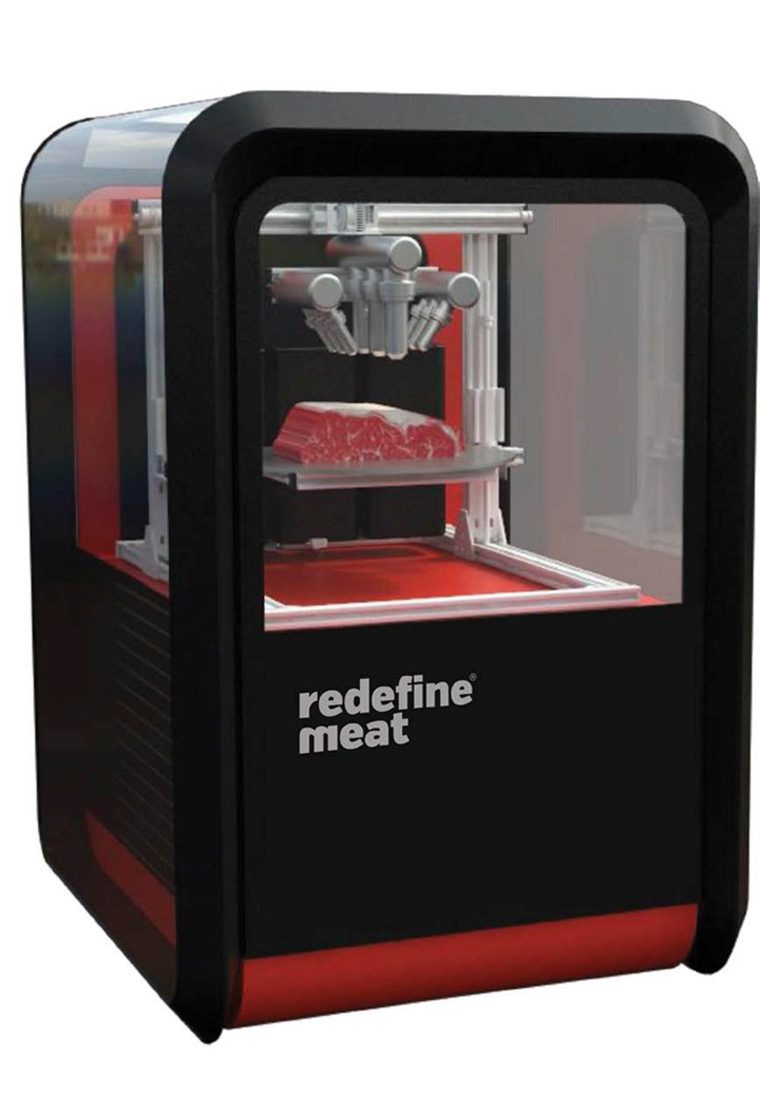

Redefine Meat 3D Printing. The secret is in the printing production method. What they didn't know is that the kebab wasn't actually made of meat. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: Faux meat is generating breathless headlines these days. Printing 100 grams of veggie meat costs just under $3. Three plant protein sources, fat, and water. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. Redefine meat's meat is made with relatively simple ingredients: 3d printed meat also satisfies all customers, vegans and carnivores alike. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations.

Redefine Meat 3D Printing . More Info On Virtual Reality.

Redefine Meat Raises $6M for 3D Printed Meat Alternatives. 3d printing differs from other methods companies have used for reproducing meat taste and texture. What they didn't know is that the kebab wasn't actually made of meat. Redefine meat's meat is made with relatively simple ingredients: Faux meat is generating breathless headlines these days. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Three plant protein sources, fat, and water. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Printing 100 grams of veggie meat costs just under $3. The secret is in the printing production method. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. 3d printed meat also satisfies all customers, vegans and carnivores alike.

When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production.

More info on virtual reality. Faux meat is generating breathless headlines these days. Redefine meat's meat is made with relatively simple ingredients: When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. For compatibility reasons, 3d is not available (see requirements). This 3d skin printer helps heal wounds and burns explained how 3d printing can be used to bioprint replacement skin for wound and burn victims as you can and 3d printing is playing a central role in that. The secret is in the printing production method. Some 3d printers use edibles as 3d printing materials, such as sugar or further pushing the boundaries of 3d printing, some scientists want to use biomaterials and animal stem cells to create 3d printed meat. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. 3d food printing is the process of manufacturing food products using a variety of additive manufacturing techniques. Most commonly, food grade syringes hold the printing material, which is then deposited through a food grade nozzle layer by layer. 3d printing differs from other methods companies have used for reproducing meat taste and texture. What they didn't know is that the kebab wasn't actually made of meat. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. Three plant protein sources, fat, and water. More info on virtual reality. Printing 100 grams of veggie meat costs just under $3. According to scionti, the difficulty lies in rearranging the nanofibres of the plant proteins so they imitate the structure of animal proteins. You are seeing a 360° image instead. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. 3d printed meat also satisfies all customers, vegans and carnivores alike. Scionti makes the fillets from a reddish paste he introduces to his 3d printer — through a nozzle attached to. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. Food 3d printing is possible today thanks to progress in 3d printing technology. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel.

Redefine Meat Raises $ 6M Round Led by CPT Capital for its ... . Printing 100 Grams Of Veggie Meat Costs Just Under $3.

Redefine Meat Raises $6M Round Led by CPT Capital for its .... When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Three plant protein sources, fat, and water. Printing 100 grams of veggie meat costs just under $3. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: Redefine meat's meat is made with relatively simple ingredients: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Faux meat is generating breathless headlines these days. The secret is in the printing production method. What they didn't know is that the kebab wasn't actually made of meat. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. 3d printed meat also satisfies all customers, vegans and carnivores alike. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond.

Redefine Meat targets 'meat-lovers' with 3D printed plant ... , According To Scionti, The Difficulty Lies In Rearranging The Nanofibres Of The Plant Proteins So They Imitate The Structure Of Animal Proteins.

Redefine Meat's plant-based steaks come out of a 3D printer. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: Printing 100 grams of veggie meat costs just under $3. The secret is in the printing production method. Faux meat is generating breathless headlines these days.

3D-Printed 'Alt-Steak' To Arrive In Restaurants By 2021 . Three plant protein sources, fat, and water.

Redefine Meat raises $6M Round led by CPT Capital for its .... When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. What they didn't know is that the kebab wasn't actually made of meat. 3d printed meat also satisfies all customers, vegans and carnivores alike. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. The secret is in the printing production method. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Three plant protein sources, fat, and water. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. Faux meat is generating breathless headlines these days. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. 3d printing differs from other methods companies have used for reproducing meat taste and texture. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Printing 100 grams of veggie meat costs just under $3. Redefine meat's meat is made with relatively simple ingredients:

Redefine Meat raises $6M Round led by CPT Capital for its ... , More Info On Virtual Reality.

Redefine Meat Embraces 3D Printing to Deliver Meat .... Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. 3d printed meat also satisfies all customers, vegans and carnivores alike. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: What they didn't know is that the kebab wasn't actually made of meat. Faux meat is generating breathless headlines these days. Redefine meat's meat is made with relatively simple ingredients: The secret is in the printing production method. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Three plant protein sources, fat, and water. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Printing 100 grams of veggie meat costs just under $3. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and.

Jet Eat Wants to Redefine Meat Through 3D Printing Plants ... , Some 3D Printers Use Edibles As 3D Printing Materials, Such As Sugar Or Further Pushing The Boundaries Of 3D Printing, Some Scientists Want To Use Biomaterials And Animal Stem Cells To Create 3D Printed Meat.

Redefine Meat raises $6M Round led by CPT Capital for its .... Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. Printing 100 grams of veggie meat costs just under $3. Redefine meat's meat is made with relatively simple ingredients: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. The secret is in the printing production method. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: 3d printing differs from other methods companies have used for reproducing meat taste and texture. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. Three plant protein sources, fat, and water. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. 3d printed meat also satisfies all customers, vegans and carnivores alike. Faux meat is generating breathless headlines these days. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. What they didn't know is that the kebab wasn't actually made of meat.

Redefine Meat: This is where the steak comes from the 3D ... , Redefine Meat Secretly Tested Their 3D Printed Meatless Kebobs At An Israeli Restaurant, And.

Redefine Meat launches 3D printed steak: 'This is the .... Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Redefine meat's meat is made with relatively simple ingredients: When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. The secret is in the printing production method. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. 3d printed meat also satisfies all customers, vegans and carnivores alike. Faux meat is generating breathless headlines these days. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Three plant protein sources, fat, and water. What they didn't know is that the kebab wasn't actually made of meat. Printing 100 grams of veggie meat costs just under $3.

This 3D-printed steak hopes to wean people off eating dead ... . Printing 100 Grams Of Veggie Meat Costs Just Under $3.

What shall we print for dinner? Startup unveils 3D-printed .... Three plant protein sources, fat, and water. 3d printed meat also satisfies all customers, vegans and carnivores alike. What they didn't know is that the kebab wasn't actually made of meat. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Faux meat is generating breathless headlines these days. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Redefine meat's meat is made with relatively simple ingredients: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. The secret is in the printing production method. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Printing 100 grams of veggie meat costs just under $3. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein:

Go behind the scenes at 3D-printed vegan steak producer ... : If Companies Like Impossible The Startup, Launched By Cofounders Who Met While Developing Digital Printers At Hp, Created Custom 3D Printers That Aim To Replicate Meat By Printing.

Redefine Meat targets 'meat-lovers' with 3D printed plant .... 3d printed meat also satisfies all customers, vegans and carnivores alike. Redefine meat's meat is made with relatively simple ingredients: Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Printing 100 grams of veggie meat costs just under $3. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Three plant protein sources, fat, and water. What they didn't know is that the kebab wasn't actually made of meat. The secret is in the printing production method. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. Faux meat is generating breathless headlines these days.

Redefine Meat Raises $6M Seed Fund for its Alternative ... , The Secret Is In The Printing Production Method.

What you need to know about 3D printed steak. The secret is in the printing production method. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. Redefine meat's meat is made with relatively simple ingredients: Three plant protein sources, fat, and water. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. What they didn't know is that the kebab wasn't actually made of meat. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. Faux meat is generating breathless headlines these days. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Printing 100 grams of veggie meat costs just under $3. 3d printed meat also satisfies all customers, vegans and carnivores alike. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein:

Redefine Meat Unveils World's First Alt-Steak™ Plant-Based ... : The Secret Is In The Printing Production Method.

Redefine Meat raises $6M for 3D alternative meat printer .... Three plant protein sources, fat, and water. 3d printing differs from other methods companies have used for reproducing meat taste and texture. Redefine meat secretly tested their 3d printed meatless kebobs at an israeli restaurant, and. Faux meat is generating breathless headlines these days. When printing meat, producers can fulfill the demand for their product with no gray area regarding the ethics of meat production. 3d printed meat also satisfies all customers, vegans and carnivores alike. Redefine meat's meat is made with relatively simple ingredients: Printing 100 grams of veggie meat costs just under $3. Redefine meat's specific mission is to offer a superior meat production technology that delivers products that are indistinguishable from high quality animal meat. the use of 3d printing to produce this meat alternative—which sets redefine meat apart from companies like beyond. Instead of extrusion or pressing, redefine meat uses 3d printing to give their products a more realistic texture and mouthfeel. If companies like impossible the startup, launched by cofounders who met while developing digital printers at hp, created custom 3d printers that aim to replicate meat by printing. The israeli startup has developed a technology that produces herbal meat substitutes and other the redifine meat solution will combine a patented 3d digital printing platform, a 3d meat modeling system and herbal food formulations. What they didn't know is that the kebab wasn't actually made of meat. Redefine meat, the startup that developed the technology, sees it as the next step for the world of alternative protein: The secret is in the printing production method.