Nasa 3D Printing Metal. Eventually, that 3d printing technology may find its way to the automotive industry. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Nasa looks to advance 3d printing construction systems for the moon and mars. This process sees a stream of. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. Editorial content, on principle, can not be bought or influenced. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. To keep all3dp free and. All3dp is an editorially independent publication. Nasa's marshall space flight center team examining the printed metal cross sections. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. These fabrics were not sewn by hand;

Nasa 3D Printing Metal : Editorial Content, On Principle, Can Not Be Bought Or Influenced.

NASA 3D Prints First Rocket Part Composed of Two Metals .... We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Nasa's marshall space flight center team examining the printed metal cross sections. Nasa looks to advance 3d printing construction systems for the moon and mars. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Eventually, that 3d printing technology may find its way to the automotive industry. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. To keep all3dp free and. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. These fabrics were not sewn by hand; Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. This process sees a stream of.

Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas.

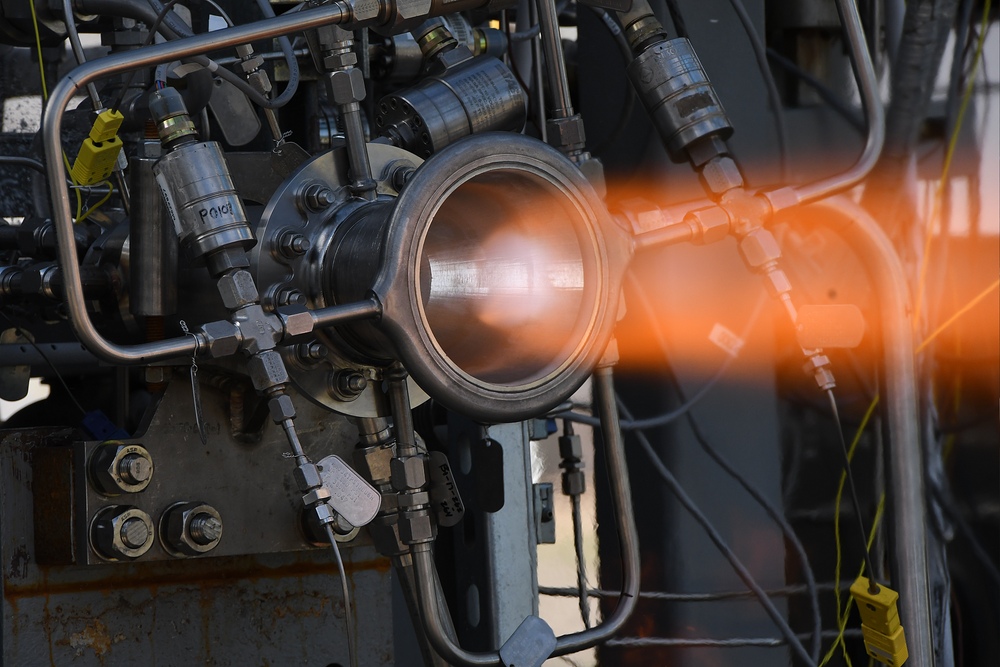

Scientists at nasa's jet propulsion laboratory. Nasa looks to advance 3d printing construction systems for the moon and mars. Read more on how new 3d printing technologies can help us build bases on the moon and be used in other creative ways in space, in the full version of the article, available to our. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. It's already experimented with rocket components that were 3d printed from a single metal. Nasa has 3d printed entire rocket engines. In space exploration, for example, industry leaders such as elon musk's spacex and nasa have fully embraced metal 3d printing as a way to produce rocket ship parts that have drastically. To make the printing process easier, nasa has even cut some of the rounded objects in half, to aid in their printing, without the need for support certainly more of nasa's 3d models will eventually be converted over to stl files for printing, as this is just the beginning of what could become quite an. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Every day new 3d models from all over the world. Plastic printing arrived first, initially used for rapid prototyping purposes, but metals and ceramics came soon after. Nasa's marshall space flight center team examining the printed metal cross sections. Spaceships are also increasingly relying on metal 3d printing. And in july, nasa announced that it had successfully tested a. Nasa's space station 3d printer is also designed to print abs, so the wrench design was specifically intended for an abs printer. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. And nasa has leased us a building at its stennis space center, in bay st. These fabrics were not sewn by hand; The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Nasa and made in space are. Since the aaa hasn't got their space tow trucks sorted out yet, the scientists at nasa are always looking for new materials and processes that. To keep all3dp free and. Eventually, that 3d printing technology may find its way to the automotive industry. Editorial content, on principle, can not be bought or influenced. Nasa 3d prints combustion chamber liners and uses 3d printing for their next move on mars. We offer these assets for your use, free and without copyright. What's more, 3d printing enables us to incorporate many more tiny cooling channels than can be produced by milling the metal. With key patents for metal printing expiring at the end of 2016, things are looking particularly exciting. Advances in 3d printing have been slow to replace traditional manufacturing, but nasa is looking toward the technology as a way to fabricate parts for rockets.

Une nouvelle technologie d'impression 3D de la Nasa pour ... : Overcoming The Problem That Prevented The Use Of 3D Printing In Space Technology Construction, Nasa's Jet Propulsion Lab, Together With Caltech And.

NASA develops 3D-printed metal fabrics for use in space .... Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Nasa looks to advance 3d printing construction systems for the moon and mars. Eventually, that 3d printing technology may find its way to the automotive industry. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. To keep all3dp free and. All3dp is an editorially independent publication. Nasa's marshall space flight center team examining the printed metal cross sections. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. These fabrics were not sewn by hand; The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. Editorial content, on principle, can not be bought or influenced. This process sees a stream of.

NASA Funds Made In Space with US$73M For Orbital 3D ... , 3D Printing Could Revolutionize Space Exploration By Helping Astronauts To Create Objects In Space And On Demand:

Fabrisonic's Whitepaper on Metal 3D Printed Heat .... To keep all3dp free and. Nasa's marshall space flight center team examining the printed metal cross sections. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. This process sees a stream of. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Editorial content, on principle, can not be bought or influenced. Nasa looks to advance 3d printing construction systems for the moon and mars.

NASA Plans to 3D Print Spacecraft in Orbit | ArchDaily - Nasa and made in space are.

3D Printer Headed for Space Station Is Ready for Launch. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. All3dp is an editorially independent publication. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Nasa looks to advance 3d printing construction systems for the moon and mars. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Editorial content, on principle, can not be bought or influenced. To keep all3dp free and. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Eventually, that 3d printing technology may find its way to the automotive industry. This process sees a stream of. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Nasa's marshall space flight center team examining the printed metal cross sections. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. These fabrics were not sewn by hand;

3D printing news Sliced: RESHAPE, GE Additive, NASA, Hawk ... : Nasa And Made In Space Are.

NASA 3D Prints First Rocket Part Composed of Two Metals .... Nasa looks to advance 3d printing construction systems for the moon and mars. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Eventually, that 3d printing technology may find its way to the automotive industry. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. This process sees a stream of. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. Nasa's marshall space flight center team examining the printed metal cross sections. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. These fabrics were not sewn by hand; To keep all3dp free and. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas.

NASA's Perseverance Rover Bringing 3D-Printed Metal Parts ... , The Inability To Print Solid 3D Objects From Several Different Alloys, A Challenging Obstacle To Using Such Parts In Spacecraft, Has Been Overcome By Nasa.

NASA to 3D Print Rocket Parts with Metal Powder and Lasers .... All3dp is an editorially independent publication. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. Eventually, that 3d printing technology may find its way to the automotive industry. To keep all3dp free and. These fabrics were not sewn by hand; Editorial content, on principle, can not be bought or influenced. Nasa looks to advance 3d printing construction systems for the moon and mars. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Nasa's marshall space flight center team examining the printed metal cross sections. This process sees a stream of. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various.

What NASA's First 3D Printed Rocket Parts Mean for the ... , All3Dp Is An Editorially Independent Publication.

Hybrid Metal 3D Printer from Made In Space Gets NASA .... Eventually, that 3d printing technology may find its way to the automotive industry. These fabrics were not sewn by hand; All3dp is an editorially independent publication. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Editorial content, on principle, can not be bought or influenced. Nasa's marshall space flight center team examining the printed metal cross sections. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. To keep all3dp free and. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Nasa looks to advance 3d printing construction systems for the moon and mars. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. This process sees a stream of.

NASA 3D Prints First Rocket Part Composed of Two Metals ... : Icon Will Work With Nasa's Marshall Space Flight Center In Huntsville, Alabama, Under The Moon To Mars Planetary Autonomous Construction Technologies (Mmpact) Project To Test Lunar Soil Simulant With Various.

NASA's JPL reveals that its Mars Perseverance rover .... All3dp is an editorially independent publication. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Nasa's marshall space flight center team examining the printed metal cross sections. To keep all3dp free and. These fabrics were not sewn by hand; Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. Eventually, that 3d printing technology may find its way to the automotive industry. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Nasa looks to advance 3d printing construction systems for the moon and mars. Editorial content, on principle, can not be bought or influenced. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. This process sees a stream of.

NASA uses 3D printing to create rocket engine alloys ... - Nasa Has 3D Printed Entire Rocket Engines.

Fabrisonic's Whitepaper on Metal 3D Printed Heat .... Nasa looks to advance 3d printing construction systems for the moon and mars. Nasa's marshall space flight center team examining the printed metal cross sections. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. This process sees a stream of. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Eventually, that 3d printing technology may find its way to the automotive industry. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. To keep all3dp free and. These fabrics were not sewn by hand; Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and.

NASA awards Pitt researchers $500K to advance metal 3D ... , The Inability To Print Solid 3D Objects From Several Different Alloys, A Challenging Obstacle To Using Such Parts In Spacecraft, Has Been Overcome By Nasa.

NASA 3D Prints Copper Rocket Part « Fabbaloo. Nasa's marshall space flight center team examining the printed metal cross sections. Editorial content, on principle, can not be bought or influenced. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. All3dp is an editorially independent publication. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas. Eventually, that 3d printing technology may find its way to the automotive industry. This process sees a stream of. These fabrics were not sewn by hand; To keep all3dp free and. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Nasa looks to advance 3d printing construction systems for the moon and mars.

NASA to launch zero gravity 3D printer into space : What's More, 3D Printing Enables Us To Incorporate Many More Tiny Cooling Channels Than Can Be Produced By Milling The Metal.

NASA's Perseverance Rover Bringing 3D-Printed Metal Parts .... We've talked about 3d printing multiple materials before, but so far it's only been done with plastics. Instead, they were made using a technique called additive manufacturing, otherwise known as 3d printing. The nasa approach eliminates the brazing step by using a hybrid 3d printing process called automated blown powder laser deposition. Overcoming the problem that prevented the use of 3d printing in space technology construction, nasa's jet propulsion lab, together with caltech and. All3dp is an editorially independent publication. These fabrics were not sewn by hand; To keep all3dp free and. Icon will work with nasa's marshall space flight center in huntsville, alabama, under the moon to mars planetary autonomous construction technologies (mmpact) project to test lunar soil simulant with various. Eventually, that 3d printing technology may find its way to the automotive industry. Nasa looks to advance 3d printing construction systems for the moon and mars. Nasa's marshall space flight center team examining the printed metal cross sections. Editorial content, on principle, can not be bought or influenced. This process sees a stream of. The inability to print solid 3d objects from several different alloys, a challenging obstacle to using such parts in spacecraft, has been overcome by nasa. Nasa's jet propulsion laboratory is developing 3d printed woven metal fabrics to use within astronaut suits and large antennas.