Infill Ratio 3D Printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Learn how to optimize these features for your 3d printed part. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. What is infill in 3d printing? .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. 3d printing infill like the octi and archi designs in the image. Shell and infill properties impact the performance and cost of fdm 3d printing.

Infill Ratio 3D Printing . Properties Would Include Wall Thickness, Filament Type, Infill.

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. What is infill in 3d printing? 3d printing infill like the octi and archi designs in the image. Besides the actual printing process, infill will affect the strength or feel of the final product. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Learn how to optimize these features for your 3d printed part. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Shell and infill properties impact the performance and cost of fdm 3d printing. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with.

Often the drill holes will go through the top and bottom layers of the.

There are several infill patterns but when looking when we look at the important factor in speed and using the least material, we look at the parameter of the best strength per weight ratio. Rectilinear is quick and does the job, kind of the. The mechanical properties would reflect the way a 3d printer creates a smooth shell of a part with lightweight but weaker core structure. Infill ratio describes the percentage of plastic filling the inside of your 3d print, under the outer layer. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Can anyone explain how the different shape causes the structure to be stronger? The infill patterns are displayed in the order of the list above, from left. A higher infill density means that there. What is infill in 3d printing? Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I want to be able to have a print be very bottom heavy and have like say 50% infill at the bottom but drop down let's say you have rectilinear infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. 3d printing infill like the octi and archi designs in the image. It's a technology that is in essence not that new, but now more than ever is getting better and accessible to everyone. Today we take a dive into the world of 3d printing and what it really has in store for us and the world in the coming years. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Thingiverse is a universe of things. 3d printing is a term that has been hyped for a long time. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Often the drill holes will go through the top and bottom layers of the. The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Consider a print with low infill that is going to be drilled and then screwed to another surface. There are several infill patterns but when looking when we look at the important factor in speed and using the least material, we look at the parameter of the best strength per weight ratio. Infill provides the 3d print with internal support as the printer builds each layer.

What is the influence of infill %, layer height and infill ... : Besides The Actual Printing Process, Infill Will Affect The Strength Or Feel Of The Final Product.

These 3D Printable Tools Help You Understand Infill .... The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Learn how to optimize these features for your 3d printed part. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Shell and infill properties impact the performance and cost of fdm 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. What is infill in 3d printing? The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. 3d printing infill like the octi and archi designs in the image. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with.

A tour around the world of 3D-printing technologies ... , Say It 5 Times Fast!

Understanding Shells, Layer Height and Infill - 4 Minutes Ago. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Learn how to optimize these features for your 3d printed part. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Shell and infill properties impact the performance and cost of fdm 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. 3d printing infill like the octi and archi designs in the image.

These 3D Printable Tools Help You Understand Infill ... , Today we take a dive into the world of 3d printing and what it really has in store for us and the world in the coming years.

3d printing news - B3D-ONLINE. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Shell and infill properties impact the performance and cost of fdm 3d printing. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. 3d printing infill like the octi and archi designs in the image. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. Learn how to optimize these features for your 3d printed part. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio.

How To Use Multiple Infill Percentages When 3D Printing ... , Infill Is Added In The Middle Of The Print So That The Shell Of The Part Is Still Stiff When You Press On It.

True 3D infill has arrived - 3D Printing Industry. Learn how to optimize these features for your 3d printed part. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Shell and infill properties impact the performance and cost of fdm 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. What is infill in 3d printing? The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. 3d printing infill like the octi and archi designs in the image. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Besides the actual printing process, infill will affect the strength or feel of the final product. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

How to Choose an Infill for your 3D prints , Say It 5 Times Fast!

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. 3d printing infill like the octi and archi designs in the image. Besides the actual printing process, infill will affect the strength or feel of the final product. Learn how to optimize these features for your 3d printed part. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Infill provides the 3d print with internal support as the printer builds each layer. Shell and infill properties impact the performance and cost of fdm 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing?

Infill with modulated stiffness for 3D Printing. More ... - Shell And Infill Properties Impact The Performance And Cost Of Fdm 3D Printing.

Infill coasters by jmdbcool - Thingiverse in 2020 .... Besides the actual printing process, infill will affect the strength or feel of the final product. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 3d printing infill like the octi and archi designs in the image. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Learn how to optimize these features for your 3d printed part. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Shell and infill properties impact the performance and cost of fdm 3d printing.

These 3D Printable Tools Help You Understand Infill ... . There Are Several Infill Patterns But When Looking When We Look At The Important Factor In Speed And Using The Least Material, We Look At The Parameter Of The Best Strength Per Weight Ratio.

First Build 3D Print File Request (Reach Spartan V Male .... Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. What is infill in 3d printing? The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. 3d printing infill like the octi and archi designs in the image. Shell and infill properties impact the performance and cost of fdm 3d printing. Learn how to optimize these features for your 3d printed part. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you.

Cliff Smyth: Discussion on Infill & Shell Parameters ... - For Those Unfamiliar, Shells Are The Outer Layers Of A Print Which Make The Walls Of An Object, Prior To The Various Infill Levels Being Printed Within.

A tour around the world of 3D-printing technologies .... The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. 3d printing infill like the octi and archi designs in the image. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Besides the actual printing process, infill will affect the strength or feel of the final product. Learn how to optimize these features for your 3d printed part. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Shell and infill properties impact the performance and cost of fdm 3d printing.

St3p3D's Tough Desktop 3D Printed Parts - 3D Printing Industry : Shell And Infill Properties Impact The Performance And Cost Of Fdm 3D Printing.

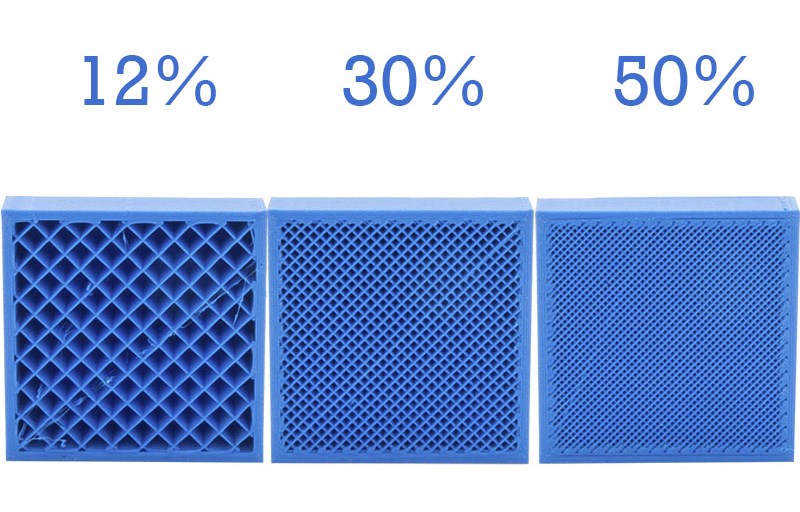

3: Infill pattern: Grid; from left to right, progressive .... Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. Learn how to optimize these features for your 3d printed part. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. 3d printing infill like the octi and archi designs in the image. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Shell and infill properties impact the performance and cost of fdm 3d printing. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing.

3D Printing for Stop-Motion Animation | 3D Printing and Art - A Higher Infill Density Means That There.

My Adventures with 3D Printed Insoles - Part 3/4 - Gyrobot .... Without it, prints wouldn't have much this allows the printer to print over empty space more accurately, and with less error. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Shell and infill properties impact the performance and cost of fdm 3d printing. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. What is infill in 3d printing? 3d printing infill like the octi and archi designs in the image. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Learn how to optimize these features for your 3d printed part. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.