Gradient Infill 3D Printing. Stronger in the vertical direction than horizontal. Has no retractions whatsoever, so it's easier to print flexible materials with. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Infill provides the 3d print with internal support as the printer builds each layer. You can see a video below and find his python code on github. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. I then tested all of them on my. I'll explain the idea and the implementation in python. For testing if this gradient infill is really more efficient, i printed two different sample types: Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. It is always tricky setting the infill for a 3d printed part. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill.

Gradient Infill 3D Printing , Greg Kourakos (3D Printing Pro On Youtube) Printers:

3D Printed Hill Gradient Reader by Dyno | Pinshape. I then tested all of them on my. Has no retractions whatsoever, so it's easier to print flexible materials with. Stronger in the vertical direction than horizontal. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. It is always tricky setting the infill for a 3d printed part. I'll explain the idea and the implementation in python. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. For testing if this gradient infill is really more efficient, i printed two different sample types: You can see a video below and find his python code on github.

Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

I'll explain the idea and the implementation in python. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. With more infill obviously comes the need for more material and more time for 3d printing, which does have consequences on strength as well. Get in touch to buy, try or hire your 3d printer. Consider a print with low infill that is going to be drilled and then screwed to another surface. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. It is always tricky setting the infill for a 3d printed part. For testing if this gradient infill is really more efficient, i printed two different sample types: Has no retractions whatsoever, so it's easier to print flexible materials with. Greg kourakos (3d printing pro on youtube) printers: Learn how to optimize these features for your 3d printed part. Best infill for strength vs material used. I'll explain the idea and the implementation in python. Basically the final 3d printed model will have different infill densities depending on the region of the model. Learn about our 3d printing software grabcad print & grabcad shop. Goprint3d specialise in 3d printers and 3d printer supplies. What is infill in 3d printing? If you haven't figured this out already. You can see a video below and find his python code on github. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. 3d printing shop management software that reduces time wasted tracking part requests. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to your creations. Will this change how you choose settings in the future? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Does this information support findings you have seen while 3d printing your own items? He printed test specimen and subjected them to bending to test the resistance against shear stress. This shape is the most efficient infill and fastest to print, the goto infill for most things. The oringinal photo can be seen below. Besides the actual printing process, infill will affect the strength or feel of the final product. Often the drill holes will go through the top and bottom layers of the. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you.

Headphone Clamp in Gradient Filament - Functional 3D ... . Visit Website For More Details Or Ring Us On 01765 694 007.

Crane 3D Printer Series | Includes the Crane Quad, Capable .... For testing if this gradient infill is really more efficient, i printed two different sample types: Has no retractions whatsoever, so it's easier to print flexible materials with. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product. I then tested all of them on my. I'll explain the idea and the implementation in python. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Infill provides the 3d print with internal support as the printer builds each layer. Stronger in the vertical direction than horizontal. It is always tricky setting the infill for a 3d printed part. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: You can see a video below and find his python code on github.

blog.tommy.sh | Early Experiments with 3D Printed Light Pipes . This Guide Is A Great Place To Start If You Are Trying To Improve The Quality Of Your 3D Printed Parts.

Weekly Roundup: Ten 3D Printable Light Up Halloween Things .... It is always tricky setting the infill for a 3d printed part. Besides the actual printing process, infill will affect the strength or feel of the final product. You can see a video below and find his python code on github. I then tested all of them on my. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Has no retractions whatsoever, so it's easier to print flexible materials with. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. I'll explain the idea and the implementation in python. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

Spaceclaim Feature: Direct Lattice Creation for ... : Often the drill holes will go through the top and bottom layers of the.

Crane 3D Printer Series | Includes the Crane Quad, Capable .... It is always tricky setting the infill for a 3d printed part. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. You can see a video below and find his python code on github. I then tested all of them on my. Has no retractions whatsoever, so it's easier to print flexible materials with. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Stronger in the vertical direction than horizontal. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. For testing if this gradient infill is really more efficient, i printed two different sample types: I'll explain the idea and the implementation in python. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer.

Headphone Clamp in Gradient Filament - Functional 3D ... . Greg Kourakos (3D Printing Pro On Youtube) Printers:

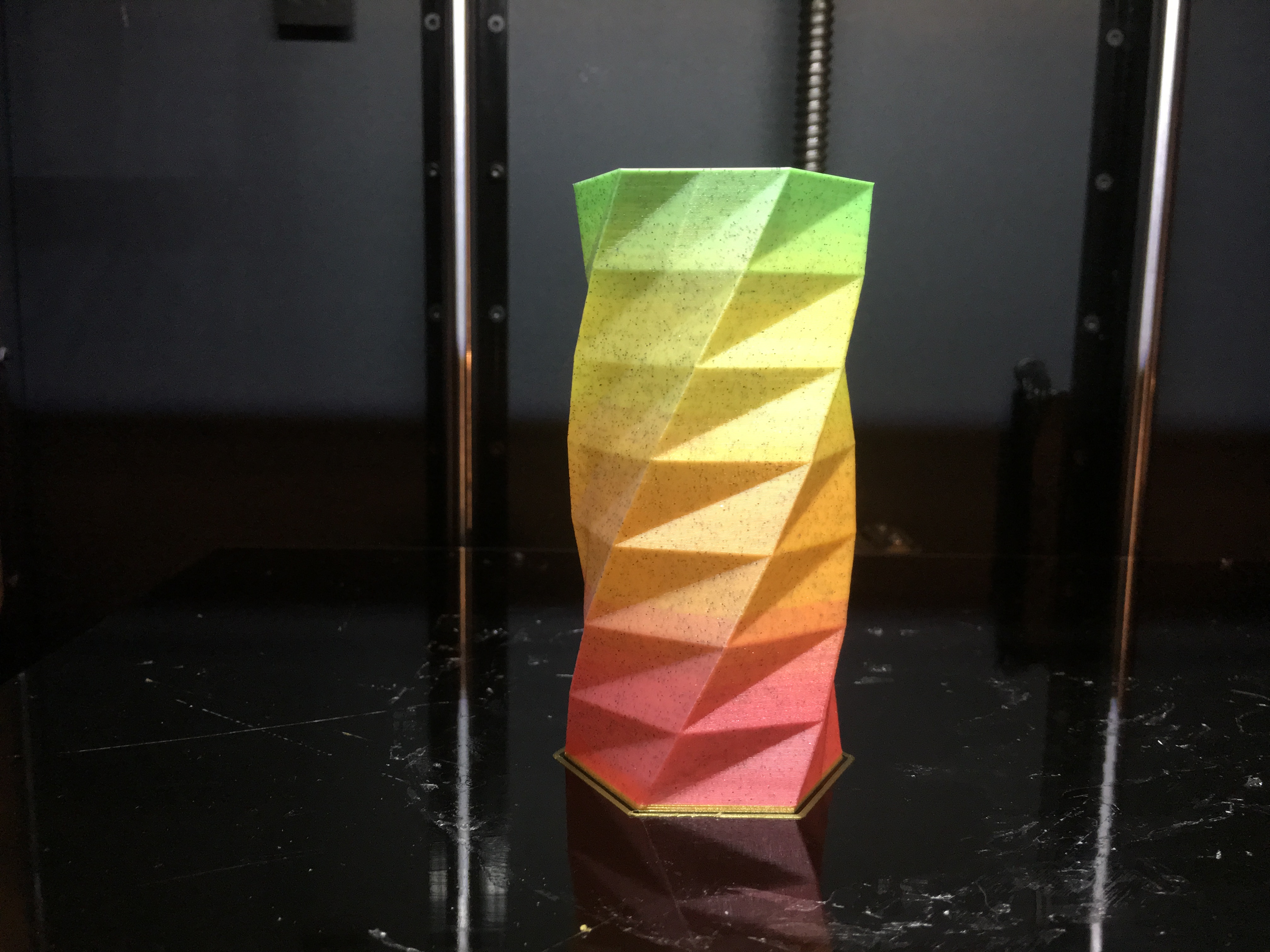

3D Printable Multicolor Gradient Hexagonal Filament by .... Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I then tested all of them on my. Stronger in the vertical direction than horizontal. I'll explain the idea and the implementation in python. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. For testing if this gradient infill is really more efficient, i printed two different sample types: Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. You can see a video below and find his python code on github. It is always tricky setting the infill for a 3d printed part. Has no retractions whatsoever, so it's easier to print flexible materials with. Besides the actual printing process, infill will affect the strength or feel of the final product. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer:

TerraPerforma - Open Thesis Fabrication 2016/17 - IAAC Blog . Consider A Print With Low Infill That Is Going To Be Drilled And Then Screwed To Another Surface.

Figure 1 from Infill Optimization for Additive .... My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Has no retractions whatsoever, so it's easier to print flexible materials with. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. For testing if this gradient infill is really more efficient, i printed two different sample types: I'll explain the idea and the implementation in python. Infill provides the 3d print with internal support as the printer builds each layer. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Besides the actual printing process, infill will affect the strength or feel of the final product. It is always tricky setting the infill for a 3d printed part. Stronger in the vertical direction than horizontal. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. You can see a video below and find his python code on github. I then tested all of them on my. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer:

Headphone Clamp in Gradient Filament - Functional 3D ... : Learn About Our 3D Printing Software Grabcad Print & Grabcad Shop.

Triangular Infill Simplify3D - YouTube. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Stronger in the vertical direction than horizontal. For testing if this gradient infill is really more efficient, i printed two different sample types: Has no retractions whatsoever, so it's easier to print flexible materials with. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. You can see a video below and find his python code on github. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. I'll explain the idea and the implementation in python. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: I then tested all of them on my. It is always tricky setting the infill for a 3d printed part. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

Download 3MF file Valorant prism tactical knife • Model to ... : Shell And Infill Properties Impact The Performance And Cost Of Fdm 3D Printing.

3D Internal Structure For Better 3D Printed Objects | Hackaday. It is always tricky setting the infill for a 3d printed part. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. For testing if this gradient infill is really more efficient, i printed two different sample types: Besides the actual printing process, infill will affect the strength or feel of the final product. I then tested all of them on my. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I'll explain the idea and the implementation in python. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Has no retractions whatsoever, so it's easier to print flexible materials with. You can see a video below and find his python code on github. Stronger in the vertical direction than horizontal.

Multicolor 3D printer filament: multicolor 3D prints with ... . I Then Tested All Of Them On My.

3D printer boat time lapse - YouTube. Stronger in the vertical direction than horizontal. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I then tested all of them on my. Besides the actual printing process, infill will affect the strength or feel of the final product. I'll explain the idea and the implementation in python. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. It is always tricky setting the infill for a 3d printed part. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. You can see a video below and find his python code on github. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. For testing if this gradient infill is really more efficient, i printed two different sample types: High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Has no retractions whatsoever, so it's easier to print flexible materials with. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Infill provides the 3d print with internal support as the printer builds each layer.

Geeetech 3d Printer 2-in-1-out Extruder Head For Mix Color ... . Learn How To Optimize These Features For Your 3D Printed Part.

Digital Fabrication // 3D Printing // Group 1 - IAAC Blog. Besides the actual printing process, infill will affect the strength or feel of the final product. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. For testing if this gradient infill is really more efficient, i printed two different sample types: Stronger in the vertical direction than horizontal. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. You can see a video below and find his python code on github. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: Has no retractions whatsoever, so it's easier to print flexible materials with. It is always tricky setting the infill for a 3d printed part. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I'll explain the idea and the implementation in python. I then tested all of them on my. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. Infill provides the 3d print with internal support as the printer builds each layer.

Spaceclaim Feature: Direct Lattice Creation for ... . Infill Provides The 3D Print With Internal Support As The Printer Builds Each Layer.

Crane 3D Printer Series | Includes the Crane Quad, Capable .... Has no retractions whatsoever, so it's easier to print flexible materials with. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. I'll explain the idea and the implementation in python. With so much customization available, and with all of the differences between 3d printers, infill should be carefully considered to fit your needs. You can see a video below and find his python code on github. Stronger in the vertical direction than horizontal. Infill provides the 3d print with internal support as the printer builds each layer. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. My usual test hook and also a simple bending bar with which for the hook i also printed a couple with different infill ratios and then applied gradient infill to the one with 25% infill. High infill parts are strong but take longer to print, while low infill prints take less time, but are weaker internally and in danger of stephan has a better answer: It is always tricky setting the infill for a 3d printed part. I then tested all of them on my. Besides the actual printing process, infill will affect the strength or feel of the final product. For testing if this gradient infill is really more efficient, i printed two different sample types: