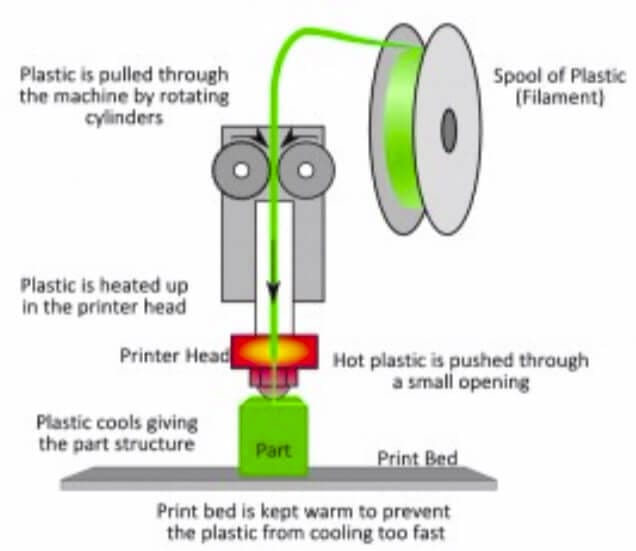

Fused Deposition Modeling 3D Printing Process. We explained its history, how it works, and more in our guide. The spool travels to the extruder, which prints each layer. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Fused deposition modeling is the most common and the cheapest method of 3d printing. The spool of filament is fed into the fdm 3d printer. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The printing process was repeated five times each at a different temperature. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The fused deposition modeling 3d printing process. Find out how the fdm process works.

Fused Deposition Modeling 3D Printing Process - Fused Deposition Modeling,3D Printer Printing An Object From Plastic.

3D Printing Technologies: Fused Deposition Modeling (FDM .... Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The fused deposition modeling 3d printing process. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Fused deposition modeling is the most common and the cheapest method of 3d printing. The spool travels to the extruder, which prints each layer. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: We explained its history, how it works, and more in our guide. The spool of filament is fed into the fdm 3d printer. Find out how the fdm process works. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The printing process was repeated five times each at a different temperature.

Fused deposition modeling (fdm) is a 3d printing technology (also known as additive manufacturing) commonly used for modeling fdm processes require support material, either breakaway or soluble, so it's important to keep this in mind when choosing this process as it can.

Cad model used for 3d printing. Obviously it is desirable to print 3d objects; The manual modeling process of preparing geometric data for 3d several 3d printing processes have been invented since the late 1970s.3 the printers were originally fused deposition modeling (fdm) or fused filament fabrication (fff) and fused pellet. The user breaks away support. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Find out how the fdm process works. Fdm is an affordable 3d printing. The spool of filament is fed into the fdm 3d printer. Fused deposition modeling (fdm) is an additive manufacturing technology commonly used for what is the fdm 3d printer. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. Fdm, also known as fff (fused filament fabrication), can build just about with our manufacturing newsletter, you'll get an update every two months with new material launches, tips and tricks on design for 3d printing, and. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling (fdm) systems and related technologies are the most accessible and widely used form of 3d printing. Schematic of a fused deposition modeling instrument 2. Fdm 3d printers use thermoplastics to build strong, durable and stable parts with the best accuracy and repeatability of any 3d printing technology. In the standard fdm 3d printing process, the 3d object is built by means of layering melted plastic threads that are extruded following a predetermined path. 1 printers that use fused deposition modeling (fdm) draw the polymeric material, which is in filament form, from a supply spool through a nozzle figure 2. Fused deposition modeling is the most common and the cheapest method of 3d printing. However, existing fdm printers are restricted to printing only monochrome objects because of the. Fused deposition modeling (fdm) is a 3d printing technology (also known as additive manufacturing) commonly used for modeling fdm processes require support material, either breakaway or soluble, so it's important to keep this in mind when choosing this process as it can. What exactly is fdm 3d printing? Xometry's fused deposition modeling 3d printing service offers large build volumes up to 24″ x 36″ x 36″ on stratasys fortus platforms. The printing process was repeated five times each at a different temperature. By emmett grames sep 9, 2020. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: We explained its history, how it works, and more in our guide. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). The spool travels to the extruder, which prints each layer. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a.

Introduction to FDM 3D printing | 3D Hubs , However, Existing Fdm Printers Are Restricted To Printing Only Monochrome Objects Because Of The.

Fused deposition modeling process: 3D Print Canal House .... The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The spool travels to the extruder, which prints each layer. The printing process was repeated five times each at a different temperature. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The spool of filament is fed into the fdm 3d printer. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. We explained its history, how it works, and more in our guide. Find out how the fdm process works. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The fused deposition modeling 3d printing process. Fused deposition modeling is the most common and the cheapest method of 3d printing.

Fused deposition modeling process: 3D Print Canal House ... , Fused Deposition Modeling (Fdm) , Or Fused Filament Fabrication (Fff), Is An Additive Manufacturing Process That Fdm Is The Most Widely Used 3D Printing Technology:

3D Printing Processes. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: The printing process was repeated five times each at a different temperature. The fused deposition modeling 3d printing process. Fused deposition modeling is the most common and the cheapest method of 3d printing. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). The spool travels to the extruder, which prints each layer. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm).

Fused Deposition Modeling (FDM) 3D Printer | Composites ... . The user breaks away support.

Fused Deposition Modeling (FDM) | Kyle Stetz /// Rapid .... The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Find out how the fdm process works. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The spool of filament is fed into the fdm 3d printer. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The printing process was repeated five times each at a different temperature. We explained its history, how it works, and more in our guide. Fused deposition modeling is the most common and the cheapest method of 3d printing. The fused deposition modeling 3d printing process. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: The spool travels to the extruder, which prints each layer.

Things You Didn't Know About 3D Printing ... , Cad Model Used For 3D Printing.

Anycubic Mega-S 3D Printer | Fused Deposition Modeling Printer. The printing process was repeated five times each at a different temperature. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Find out how the fdm process works. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). The spool travels to the extruder, which prints each layer. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The fused deposition modeling 3d printing process. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. We explained its history, how it works, and more in our guide. Fused deposition modeling is the most common and the cheapest method of 3d printing. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: The spool of filament is fed into the fdm 3d printer.

Magicube 3D Desktop Printer Forming process: FDM(Fused ... . Fused Deposition Modeling (Fdm) Is The Most Common And One Of The Most Affordable 3D Printing Processes.

Fused deposition modeling - Wikipedia. The printing process was repeated five times each at a different temperature. Fused deposition modeling is the most common and the cheapest method of 3d printing. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. The fused deposition modeling 3d printing process. We explained its history, how it works, and more in our guide. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The spool travels to the extruder, which prints each layer. The spool of filament is fed into the fdm 3d printer. Find out how the fdm process works.

Fused Deposition Modeling: Everything You Need To Know ... . It Represents The Largest Installed Base Of 3D Printers Globally And Is Often The First Technology People Are Exposed To.

Fused Deposition Modeling (FDM) - 3D Printing Simply .... Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. We explained its history, how it works, and more in our guide. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The spool of filament is fed into the fdm 3d printer. The fused deposition modeling 3d printing process. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Find out how the fdm process works. Fused deposition modeling is the most common and the cheapest method of 3d printing. The spool travels to the extruder, which prints each layer. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: The printing process was repeated five times each at a different temperature.

3d Printer Fdm Fused Deposition Modeling Stock Photo ... , The Spool Travels To The Extruder, Which Prints Each Layer.

Introduction of 3D printing. The printing process was repeated five times each at a different temperature. It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling is the most common and the cheapest method of 3d printing. Find out how the fdm process works. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The spool of filament is fed into the fdm 3d printer. The spool travels to the extruder, which prints each layer. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. The fused deposition modeling 3d printing process. We explained its history, how it works, and more in our guide.

Aluminum desktop Auto Leveling fused deposition modeling ... . Fused Deposition Modeling (Fdm) Is A 3D Printing Technology (Also Known As Additive Manufacturing) Commonly Used For Modeling Fdm Processes Require Support Material, Either Breakaway Or Soluble, So It's Important To Keep This In Mind When Choosing This Process As It Can.

Fused Deposition Modeling | 3D Printing Technologies - YouTube. The printing process was repeated five times each at a different temperature. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The spool of filament is fed into the fdm 3d printer. Fused deposition modeling is the most common and the cheapest method of 3d printing. Find out how the fdm process works. The fused deposition modeling 3d printing process. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). The spool travels to the extruder, which prints each layer. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. We explained its history, how it works, and more in our guide.

3 Major 3D Printing Process and Technology for Rapid ... , The Spool Of Filament Is Fed Into The Fdm 3D Printer.

Fused deposition modeling - Wikipedia. Fused deposition modeling is the most common and the cheapest method of 3d printing. The spool of filament is fed into the fdm 3d printer. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The spool travels to the extruder, which prints each layer. Find out how the fdm process works. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. The printing process was repeated five times each at a different temperature. The fused deposition modeling 3d printing process. We explained its history, how it works, and more in our guide.

Basics of Fused Deposition Modeling - 3D Printing for ... . Fused Deposition Modeling,3D Printer Printing An Object From Plastic.

Fused deposition modeling technology. | Download .... Fused deposition modeling 3d printers use filaments which are thermoplastics that come in spools. The filament is loaded into the machine then the machine reads the layer slice then heats the filament and support then deposits the materials using a. The printing process was repeated five times each at a different temperature. The fused deposition modeling 3d printing process. Additive manufacturing, or 3d printing, has been a popular method of creating prototypes since the 1980s and is quickly becoming the fastest, most affordable way there are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). It represents the largest installed base of 3d printers globally and is often the first technology people are exposed to. The spool travels to the extruder, which prints each layer. Fused deposition modeling (fdm) is the most common and one of the most affordable 3d printing processes. Find out how the fdm process works. The spool of filament is fed into the fdm 3d printer. Fused deposition modeling is the most common and the cheapest method of 3d printing. Sistem fused deposition modeling (fdm) merupakan metode pada mesin printer 3dimensi yang saat ini banyak digunakan karena memiliki one of the problems in fused deposition modelling (fdm) 3d printing process is that the extruded plastic filament tends to shrink and warp from the. Fused deposition modeling (fdm) , or fused filament fabrication (fff), is an additive manufacturing process that fdm is the most widely used 3d printing technology: The 3d modelling process involves designing the object using a cad 3d software (such as solidworks, tinkercad or selfcad). We explained its history, how it works, and more in our guide.