Exone Metal 3D Printing Process. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. First, it lays down a layer of powdered metal. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Desktop metal , exone , digital metal , hp. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.

Exone Metal 3D Printing Process . This Short Clip Shows The Metal 3D Printing Process Using Exone's Exclusive Binder Jetting Technology.

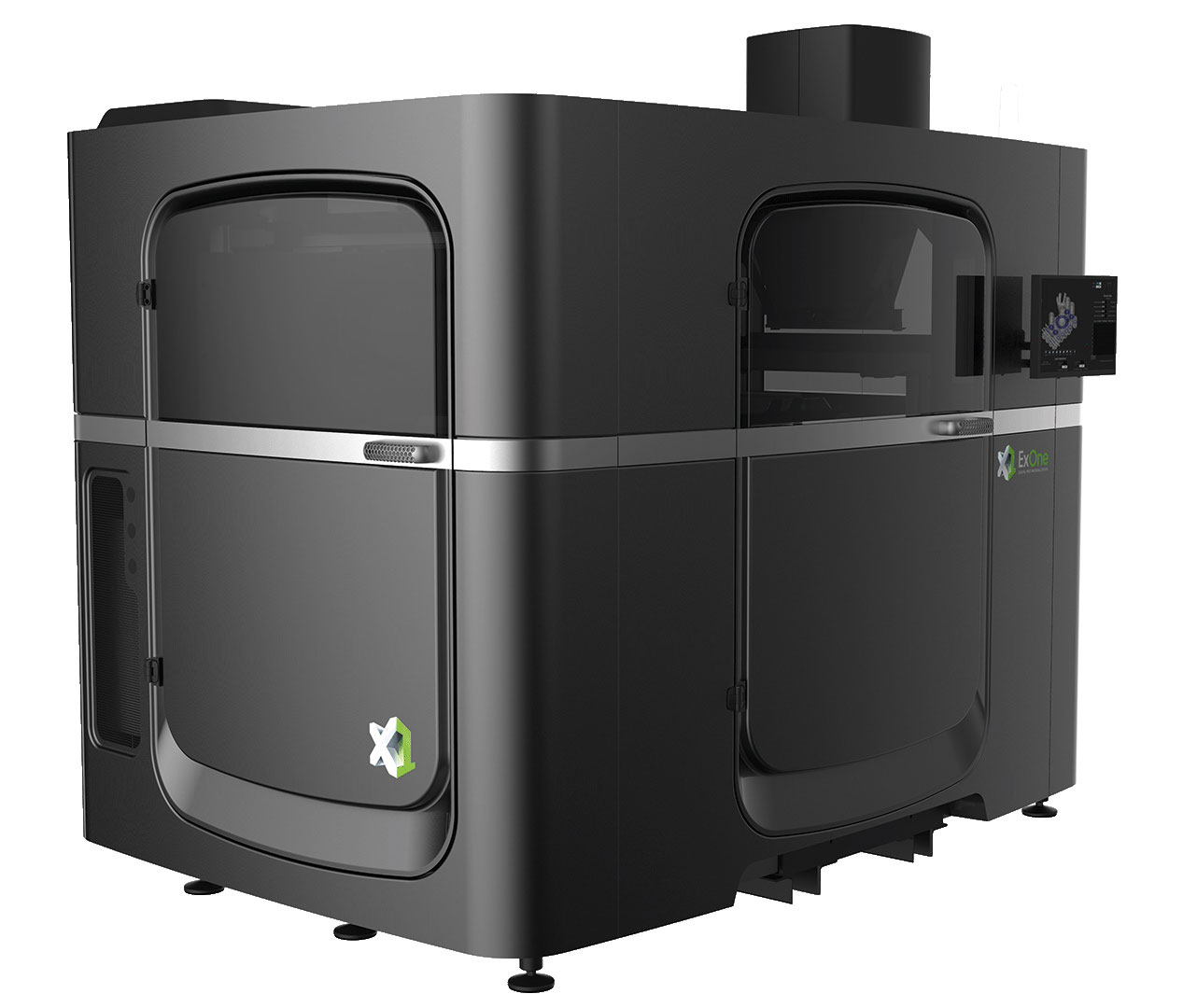

The ExOne X1 25PRO 3D Printer. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Desktop metal , exone , digital metal , hp. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. First, it lays down a layer of powdered metal. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Видео exone metal 3d printing process канала exone. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology.

Exone metal 3d printing process.

First, it lays down a layer of powdered metal. Once the process is over, an the metal binder jetting technology was developed by the company exone since 1996. When the printing process is complete, the build box is removed from the printer and placed into an oven for curing. Exone metal 3d printing process. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. Way ahead of its time! First, it lays down a layer of powdered metal. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. The german company's 3d printers are. This fragile model is then put in an oven where it is sintered while digital metal's build volumes are very small. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. The surface quality, level of detail and accuracy make it a very mature process for printing out tiny metal. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Metal 3d printing has been one of the most outstanding developments in the am industry in recent years. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Innoventpro rounds out exone's full family of production metal binder jetting systems and accessories, which now includes the x1d1 automated guided binder jetting is a groundbreaking 3d printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand. Desktop metal , exone , digital metal , hp. Exone company is an expert in binder jetting 3d printing technology applied to sand, metal and ceramic materials. Binder jetting technology is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. In 2018, wohlers report reported that 80 exone is a publicly traded german manufacturing company that specialises in industrial 3d printing machines. Exone metal 3d printing process. The exone metal printing process works by depositing binder on a metal powder. The 3d metal printer receives its instructions from the computer which instructs the laser what shape to.

3D Printing and COVID-19: Reusable Metal Filters Being ... - The German Company's 3D Printers Are.

ExOne pushes to make metal 3D printing green - TCT Magazine. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Desktop metal , exone , digital metal , hp. First, it lays down a layer of powdered metal. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.

ExOne to Partner with Xometry to Offer Metal Binder ... . Exone Company Is An Expert In Binder Jetting 3D Printing Technology Applied To Sand, Metal And Ceramic Materials.

ExOne | Innovent+. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Binder jetting of metal was then licensed to exone in 1995. First, it lays down a layer of powdered metal. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density.

ExOne to Partner with Xometry to Offer Metal Binder ... - Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.

ExOne | Binder Jet 3D Printing Metal for Manufacturing. Видео exone metal 3d printing process канала exone. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Desktop metal , exone , digital metal , hp. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. First, it lays down a layer of powdered metal. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

ExOne | ExOne Adds Two New Stainless Steels to Updated ... , When Printing Metals, The Final Part Must Be Sintered In Order To Fuse The Particles Together Into A Solid Object.

ExOne launches new metal X1 160PRO 3D printer - 3Dnatives. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. First, it lays down a layer of powdered metal. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Desktop metal , exone , digital metal , hp. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

The ExOne X1 25PRO 3D Printer : Exone Company Is An Expert In Binder Jetting 3D Printing Technology Applied To Sand, Metal And Ceramic Materials.

ExOne appoint new CEO - 3D Printing Industry. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Desktop metal , exone , digital metal , hp. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. First, it lays down a layer of powdered metal. Видео exone metal 3d printing process канала exone.

3Dnatives . Exone Company Is An Expert In Binder Jetting 3D Printing Technology Applied To Sand, Metal And Ceramic Materials.

ExOne M-Flex 3D Metal Printer - Machine Animation - YouTube. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. First, it lays down a layer of powdered metal. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Desktop metal , exone , digital metal , hp. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Видео exone metal 3d printing process канала exone.

ExOne 3D prints steel necklace - Materials Today . This Video Demonstrates The Process And Technology Involved In Creating Dense, Usable Parts In Industrial Grade Materials.

ExOne appoint new CEO - 3D Printing Industry. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. First, it lays down a layer of powdered metal. Desktop metal , exone , digital metal , hp. Видео exone metal 3d printing process канала exone. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.

ExOne joins Xometry network as exclusive metal binder jet ... : In 2018, Wohlers Report Reported That 80 Exone Is A Publicly Traded German Manufacturing Company That Specialises In Industrial 3D Printing Machines.

ExOne forms multiple partnerships to simplify sintering .... This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. First, it lays down a layer of powdered metal. Видео exone metal 3d printing process канала exone. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Binder jetting of metal was then licensed to exone in 1995. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Desktop metal , exone , digital metal , hp.

ExOne forms multiple partnerships to simplify sintering ... , The German Company's 3D Printers Are.

ExOne launches X1 160PRO, its largest metal binder jetting .... Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. First, it lays down a layer of powdered metal. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Desktop metal , exone , digital metal , hp. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. Binder jetting of metal was then licensed to exone in 1995. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.

ExOne Introduce New Nickel-based Inconel(R) Alloy 625 For ... . Desktop Metal , Exone , Digital Metal , Hp.

MatterFab Reveals Their Affordable Metal 3D Printer, 'An .... Since exone leverages mim powders in metal 3d printing, the conceptual models showcase the characteristics that will be present after the injection molding process is complete for. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object. This short clip shows the metal 3d printing process using exone's exclusive binder jetting technology. The exone research team has been 3d printing a variety of nanoparticles suspended in its exone binder jet systems now process more than 20 metal, ceramic and composite materials. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. First, it lays down a layer of powdered metal. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. They are typically produced in powder form and must meet certain characteristics, like particle shape and size, and powder density. Видео exone metal 3d printing process канала exone. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Desktop metal , exone , digital metal , hp. Binder jetting of metal was then licensed to exone in 1995. This video demonstrates the process and technology involved in creating dense, usable parts in industrial grade materials. Exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production.