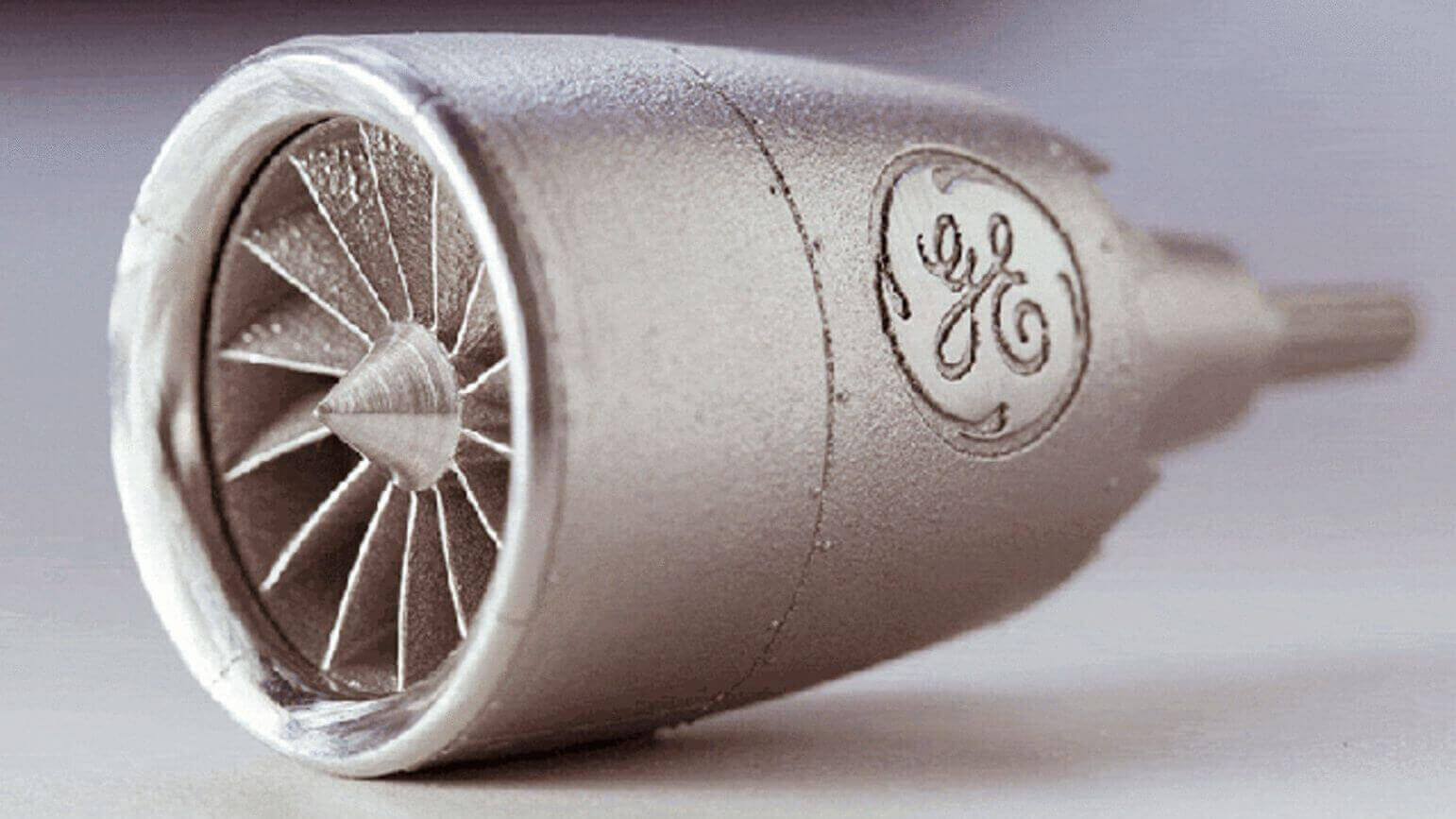

Can You 3D Printing Metal. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Curious about how 3d printing can benefit your business? Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. Look no further than our own additive manufacturing consultancy or 3d printing. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. So metal printing companies created several different approaches. Only two of them are widely used. The first one is called binder jetting. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Metal 3d printing is changing the way we create parts. This set of gripper jaws, for example, moves pieces of sheet metal to. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. The ability to print metal objects is still in its infancy.

Can You 3D Printing Metal - Applications For Metal Am Systems.

Mercedes-Benz Reveals First Metal 3D Printed Truck Part .... Curious about how 3d printing can benefit your business? So metal printing companies created several different approaches. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Look no further than our own additive manufacturing consultancy or 3d printing. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. Only two of them are widely used. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. The ability to print metal objects is still in its infancy. Metal 3d printing is changing the way we create parts. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. This set of gripper jaws, for example, moves pieces of sheet metal to. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. The first one is called binder jetting.

Sculpteo's online 3d printing service for prototyping and production.

Only a couple of years. The ability to print metal objects is still in its infancy. Is that the same filament like those. The first attempts to print with metal can be traced back to the 1880s when the first welders used carbon electrode arcs to fuse two pieces of metal. Using 3d printing for metal can also be applied to recycling aspects of pieces that are not suited to modern tastes as explained in this video: If you have a 3d cad model of your part ready, upload it online now to receive an interactive quote with free design for manufacturability feedback within hours. When modifications are needed to the design, the only additional cost is to 3d print the updated design. The technology can produce complex shapes that are not possible with traditional casting and machining methods, or subtractive techniques. These are then directly used to create a metal prototype. So metal printing companies created several different approaches. Well, the technology is already here. We are here to support these industries with our medical grade durable usp class vi materials in this time of uncertain supply chains, and. With ultimaker 3d printers, sylatech can create a 3d printed model of the customer's design in a matter of days. Takes these questions to the experts at oregon state. A full list of the eos m 290's specifications can be found on padt's website here. Two technologies on the horizon will offer us even higher resolution parts. While you can 3d print individual glasses frames, as you see in the video above, that is not the most efficient use for the. Get an instant quote and your we 3d print it. Metal 3d printing services located in for just $65 and the cost of a trip to japan, you can have a gummi bear that looks just like you. Metal 3d printing provides many benefits to aerospace and defense companies, including lighter, cheaper parts made much faster and with fewer constraints than with traditional manufacturing methods. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. The first one is called binder jetting. You can find the previous parts of this series comparing metal 3d printing technologies here, covering powder bed fusion and directed energy deposition desktop metal is a $200m funded start up which brings together a lot of very talented 3d printing and materials people. Curious about how 3d printing can benefit your business? Sculpteo's online 3d printing service for prototyping and production. Additive manufacturing of new england. Metal 3d printing is changing the way we create parts. Metal 3d printer 3d printing service making out new england. If you don't find the content relevant, you can unsubscribe with one click. Printers that work directly with metals are generally expensive. This metal 3d printer can be operated remotely via a tablet application, which also gives access to its onboard camera stream.

NVBOTS' 3D printer can make one component in 21 different ... - How Can You 3D Print Solid Metal?

Metal 3D Printing at home! - Bitfab. The first one is called binder jetting. Only two of them are widely used. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. So metal printing companies created several different approaches. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. Curious about how 3d printing can benefit your business? The ability to print metal objects is still in its infancy. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Look no further than our own additive manufacturing consultancy or 3d printing. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Metal 3d printing is changing the way we create parts. This set of gripper jaws, for example, moves pieces of sheet metal to. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid.

3D Printing Copper: How to Get Copper 3D Prints | All3DP , Renishaw Is A Systems Manufacturer And Solutions Provider For Additive Manufacturing (Am).

Prototyping: Six Things You Didn't Know You Can 3D Print. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Look no further than our own additive manufacturing consultancy or 3d printing. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. Metal 3d printing is changing the way we create parts. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. This set of gripper jaws, for example, moves pieces of sheet metal to. The first one is called binder jetting.

Shapeways: metal 3D printing in Titanium contest ... . In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid.

New filament means you can print metal on any 3D printer .... This set of gripper jaws, for example, moves pieces of sheet metal to. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: The first one is called binder jetting. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. So metal printing companies created several different approaches. The ability to print metal objects is still in its infancy. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Curious about how 3d printing can benefit your business? Metal 3d printing is changing the way we create parts. Look no further than our own additive manufacturing consultancy or 3d printing. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. Only two of them are widely used. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more.

Shapeways: metal 3D printing in Titanium contest ... . The First One Is Called Binder Jetting.

The Metal 3D Printer Buyer's Guide | All3DP Pro. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Metal 3d printing is changing the way we create parts. Only two of them are widely used. Look no further than our own additive manufacturing consultancy or 3d printing. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. This set of gripper jaws, for example, moves pieces of sheet metal to. Curious about how 3d printing can benefit your business? But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. The ability to print metal objects is still in its infancy. So metal printing companies created several different approaches. The first one is called binder jetting.

World's First 3D Printer Metal Gun Hits Bullseyes - Off ... . Takes These Questions To The Experts At Oregon State.

Industrial-Grade 3D Printers : metal 3d printer. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. The ability to print metal objects is still in its infancy. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: This set of gripper jaws, for example, moves pieces of sheet metal to. Metal 3d printing is changing the way we create parts. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. The first one is called binder jetting. Only two of them are widely used. Look no further than our own additive manufacturing consultancy or 3d printing. Curious about how 3d printing can benefit your business? So metal printing companies created several different approaches. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more.

How Much Does a Metal 3D Printer Cost in 2019? | All3DP - How Can You 3D Print Solid Metal?

Mercedes-Benz Reveals First Metal 3D Printed Truck Part .... Only two of them are widely used. The first one is called binder jetting. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Look no further than our own additive manufacturing consultancy or 3d printing. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. Metal 3d printing is changing the way we create parts. This set of gripper jaws, for example, moves pieces of sheet metal to. The ability to print metal objects is still in its infancy. So metal printing companies created several different approaches. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Curious about how 3d printing can benefit your business?

2019 Metal 3D Printer Guide - All About Metal 3D Printing ... , With Ultimaker 3D Printers, Sylatech Can Create A 3D Printed Model Of The Customer's Design In A Matter Of Days.

NVBOTS' 3D printer can make one component in 21 different .... The first one is called binder jetting. Look no further than our own additive manufacturing consultancy or 3d printing. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. Metal 3d printing is changing the way we create parts. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Only two of them are widely used. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Curious about how 3d printing can benefit your business? Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. The ability to print metal objects is still in its infancy. This set of gripper jaws, for example, moves pieces of sheet metal to. So metal printing companies created several different approaches. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more.

The top 7 design tips for 3D metal printing , Curious About How 3D Printing Can Benefit Your Business?

New filament means you can print metal on any 3D printer .... Metal 3d printing is changing the way we create parts. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. The first one is called binder jetting. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Only two of them are widely used. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. So metal printing companies created several different approaches. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Curious about how 3d printing can benefit your business? This set of gripper jaws, for example, moves pieces of sheet metal to. Look no further than our own additive manufacturing consultancy or 3d printing. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. The ability to print metal objects is still in its infancy.

How Much Does a Metal 3D Printer Cost in 2019? | All3DP : Renishaw Is A Systems Manufacturer And Solutions Provider For Additive Manufacturing (Am).

3D Printing Copper: How to Get Copper 3D Prints | All3DP. Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Metal 3d printing is changing the way we create parts. The first one is called binder jetting. Look no further than our own additive manufacturing consultancy or 3d printing. The ability to print metal objects is still in its infancy. So metal printing companies created several different approaches. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. This set of gripper jaws, for example, moves pieces of sheet metal to. Only two of them are widely used. Curious about how 3d printing can benefit your business? Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate.

Can This Metal 3D Printing System Make Production Additive ... , We Are Here To Support These Industries With Our Medical Grade Durable Usp Class Vi Materials In This Time Of Uncertain Supply Chains, And.

3D Printing Copper: How to Get Copper 3D Prints | All3DP. Metal 3d printing is changing the way we create parts. This set of gripper jaws, for example, moves pieces of sheet metal to. 3d metal printing can help you to create impossible designs that are lightweight, strong and ideal for demanding applications in aerospace, automotive, medical and more. But it's growing up quickly, allowing for lighter and more complex designs than with traditional methods. The ability to print metal objects is still in its infancy. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Metal 3d printing has come a long way in the last few years and it continues to get bigger (and smaller), faster, more precise, cheaper, and easier to use. In the metal 3d printing process, a number of issues can occur that machine operators attempt to avoid. But to get the most from metal 3d printing technology it's critical that you adhere to certain engineering and design rules appropriate. Only two of them are widely used. So metal printing companies created several different approaches. Look no further than our own additive manufacturing consultancy or 3d printing. The first one is called binder jetting. Leading producer of metal powders for additive manufacturing, praxair surface technologies, shows you how 3d metal printing works. Curious about how 3d printing can benefit your business?