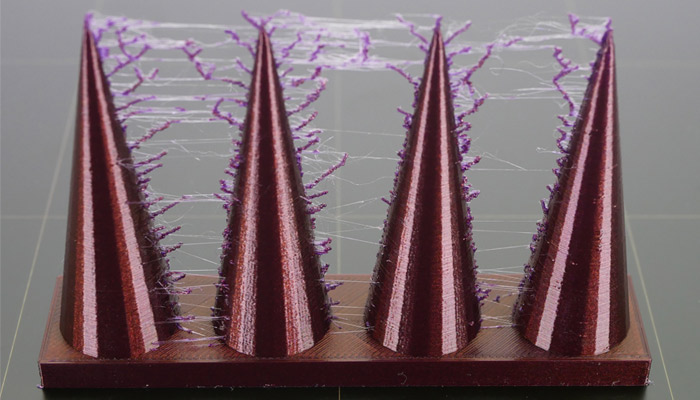

3D Printing Retraction Problems. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. Following the first episode's success, i decided to keep going. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. A common problem encountered with plastic extrusion 3d printers is stripped filament. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. I've been having major problems with stringing on my sindoh 3dwox printer. Overcome this issue with these 5 simple solutions. So much more to come as the requests for assistance keep coming in :)if you have any 3d. I've been printing these blocks all morning long and still have issues. This is because the most common aesthetic issues originate from. The extruder of a 3d printer is the mechanism that. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. This represents about the worst oozing/stringing possible on this machine. If you want flawless prints then you need to adjust properly your retraction settings. In 3d printing, stringing is a common problem, especially with flexible materials.

3D Printing Retraction Problems : Are You Referring To Frequency Or Distance Of Retraction?

Retraction vs ABS cooling? - Ultimaker Cura - Ultimaker .... Overcome this issue with these 5 simple solutions. The extruder of a 3d printer is the mechanism that. This is because the most common aesthetic issues originate from. So much more to come as the requests for assistance keep coming in :)if you have any 3d. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. If you want flawless prints then you need to adjust properly your retraction settings. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. In 3d printing, stringing is a common problem, especially with flexible materials. I've been having major problems with stringing on my sindoh 3dwox printer. A common problem encountered with plastic extrusion 3d printers is stripped filament. This represents about the worst oozing/stringing possible on this machine. Following the first episode's success, i decided to keep going. I've been printing these blocks all morning long and still have issues.

Retraction can easily be activated through your slicer software and can even be tweaked through a few settings.

Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Offcourse, it is difficult to join two pieces of filament together without leaving any mark, but there are several tools in simplify3d that can be used to. Too much and the molten filament will solidify further up the nozzle, possibly. These 3d printing problems are typical signs that the print bed hasn't been leveled properly. At the base of the model, the print bends upwards until it's no longer level with the retraction is an important factor when it comes to quality of finish and can be enabled through most slicing software. This is because the most common aesthetic issues originate from. We have compiled an extensive list of the most common 3d use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. A common problem encountered with plastic extrusion 3d printers is stripped filament. I've been having major problems with stringing on my sindoh 3dwox printer. My printed objects have horizontal holes in them (as seen i the picture below) looking carefully at the printing process i can see that after a retraction there's a small amount of time the hotend isn't extruding plastic. The retraction of the filament prevents the liquid material from escaping through the. I have many frequent retractions but don't have a noticeable problem with the geometry. After the 3d print of a section, the retract function causes the material to retract into the nozzle. Slipping of the filament drive during retraction. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. By retracting, it means that pulling 3d printing problems can be easily reduced to null when reading thoroughly. Overcome this issue with these 5 simple solutions. Are you referring to frequency or distance of retraction? I've been printing these blocks all morning long and still have issues. Below you'll find a list of the problems we cover in this article. Going through every guideline and ensuring that you know in and out. This article should help you identify the different problems related to 3d printing. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. Other problems with the same symptoms: This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. See what people are saying on from bad to worse: Following the first episode's success, i decided to keep going. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. The retraction works by retracting the. This might help me fix my problems too.

3D Printer Retraction Speed - What Does It Mean? | All3DP , The 3D Printing Experts Use This Method Most Of The Time To Avoid Stringing Problem.

2019 Troubleshooting Guide to Common 3D Printing Problems .... If you want flawless prints then you need to adjust properly your retraction settings. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. The extruder of a 3d printer is the mechanism that. This is because the most common aesthetic issues originate from. In 3d printing, stringing is a common problem, especially with flexible materials. I've been having major problems with stringing on my sindoh 3dwox printer. So much more to come as the requests for assistance keep coming in :)if you have any 3d. Following the first episode's success, i decided to keep going. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Overcome this issue with these 5 simple solutions. This represents about the worst oozing/stringing possible on this machine. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. I've been printing these blocks all morning long and still have issues. A common problem encountered with plastic extrusion 3d printers is stripped filament. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with.

The Prometheus System - Intuitive Multi-Filament 3D ... , Most Problems You Run Into Are Already Common To Other Hobbyists In The 3D Printing Community.

Identify and correct 3D printing problems ・ Cults. This represents about the worst oozing/stringing possible on this machine. Overcome this issue with these 5 simple solutions. I've been having major problems with stringing on my sindoh 3dwox printer. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. If you want flawless prints then you need to adjust properly your retraction settings. In 3d printing, stringing is a common problem, especially with flexible materials. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. So much more to come as the requests for assistance keep coming in :)if you have any 3d. Following the first episode's success, i decided to keep going.

3D Printer Retraction Speed - What Does It Mean? | All3DP : A common problem encountered with plastic extrusion 3d printers is stripped filament.

extruder - Retraction Causing Skipping - 3D Printing Stack .... We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. If you want flawless prints then you need to adjust properly your retraction settings. This represents about the worst oozing/stringing possible on this machine. In 3d printing, stringing is a common problem, especially with flexible materials. I've been having major problems with stringing on my sindoh 3dwox printer. A common problem encountered with plastic extrusion 3d printers is stripped filament. The extruder of a 3d printer is the mechanism that. I've been printing these blocks all morning long and still have issues. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. This is because the most common aesthetic issues originate from. Overcome this issue with these 5 simple solutions. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. So much more to come as the requests for assistance keep coming in :)if you have any 3d. Following the first episode's success, i decided to keep going.

Fan installation (Page 1) — Hacks & Mods — SoliForum - 3D ... : Its Function Is Pretty Simple And.

3D Printer Retraction Speed - What Does It Mean? | All3DP. This represents about the worst oozing/stringing possible on this machine. I've been printing these blocks all morning long and still have issues. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. So much more to come as the requests for assistance keep coming in :)if you have any 3d. This is because the most common aesthetic issues originate from. If you want flawless prints then you need to adjust properly your retraction settings. In 3d printing, stringing is a common problem, especially with flexible materials. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. Overcome this issue with these 5 simple solutions. I've been having major problems with stringing on my sindoh 3dwox printer. The extruder of a 3d printer is the mechanism that. Following the first episode's success, i decided to keep going. A common problem encountered with plastic extrusion 3d printers is stripped filament. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right.

The Insidious Problem of 3D Print Retraction : The Extruder Of A 3D Printer Is The Mechanism That.

Common 3D printing problem: Stringing - Ira3D Team - Medium. Following the first episode's success, i decided to keep going. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. If you want flawless prints then you need to adjust properly your retraction settings. This represents about the worst oozing/stringing possible on this machine. In 3d printing, stringing is a common problem, especially with flexible materials. I've been printing these blocks all morning long and still have issues. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. A common problem encountered with plastic extrusion 3d printers is stripped filament. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. The extruder of a 3d printer is the mechanism that. So much more to come as the requests for assistance keep coming in :)if you have any 3d. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. I've been having major problems with stringing on my sindoh 3dwox printer. This is because the most common aesthetic issues originate from. Overcome this issue with these 5 simple solutions.

Review: Copymaster 3D 300 desktop 3D printer - 3D Printing ... , Most Problems You Run Into Are Already Common To Other Hobbyists In The 3D Printing Community.

Inconsistent Extrusion · Issue #602 · prusa3d/Prusa .... Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. Overcome this issue with these 5 simple solutions. So much more to come as the requests for assistance keep coming in :)if you have any 3d. I've been printing these blocks all morning long and still have issues. If you want flawless prints then you need to adjust properly your retraction settings. In 3d printing, stringing is a common problem, especially with flexible materials. The extruder of a 3d printer is the mechanism that. This is because the most common aesthetic issues originate from. This represents about the worst oozing/stringing possible on this machine. A common problem encountered with plastic extrusion 3d printers is stripped filament. Following the first episode's success, i decided to keep going. I've been having major problems with stringing on my sindoh 3dwox printer.

Most Common 3D Printing Problems with Solutions ... - After The 3D Print Of A Section, The Retract Function Causes The Material To Retract Into The Nozzle.

Musings on Blobbing and Stringing - Part 2 | Sublime Layers. Following the first episode's success, i decided to keep going. A common problem encountered with plastic extrusion 3d printers is stripped filament. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. The extruder of a 3d printer is the mechanism that. This is because the most common aesthetic issues originate from. I've been printing these blocks all morning long and still have issues. Overcome this issue with these 5 simple solutions. In 3d printing, stringing is a common problem, especially with flexible materials. This represents about the worst oozing/stringing possible on this machine. So much more to come as the requests for assistance keep coming in :)if you have any 3d. If you want flawless prints then you need to adjust properly your retraction settings. I've been having major problems with stringing on my sindoh 3dwox printer.

Common 3D printing problem: Stringing - Ira3D Team - Medium : Hunter626103D Printers 3D Printing 3D Printers.

creality cr 10 - Question about retraction distance and .... The extruder of a 3d printer is the mechanism that. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. A common problem encountered with plastic extrusion 3d printers is stripped filament. Following the first episode's success, i decided to keep going. If you want flawless prints then you need to adjust properly your retraction settings. So much more to come as the requests for assistance keep coming in :)if you have any 3d. I've been printing these blocks all morning long and still have issues. This is because the most common aesthetic issues originate from. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. Overcome this issue with these 5 simple solutions. This represents about the worst oozing/stringing possible on this machine. I've been having major problems with stringing on my sindoh 3dwox printer. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. In 3d printing, stringing is a common problem, especially with flexible materials.

Troubleshooting Guide to 24 Common 3D Printing Problems ... : I Have Printed A 3Dbenchy Prior To Changing The Retraction To Have A Control.

A visual Ultimaker troubleshooting guide - 3DVerkstan .... I've been printing these blocks all morning long and still have issues. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. The extruder of a 3d printer is the mechanism that. Overcome this issue with these 5 simple solutions. A common problem encountered with plastic extrusion 3d printers is stripped filament. So much more to come as the requests for assistance keep coming in :)if you have any 3d. This is because the most common aesthetic issues originate from. Following the first episode's success, i decided to keep going. If you want flawless prints then you need to adjust properly your retraction settings. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. I've been having major problems with stringing on my sindoh 3dwox printer. This represents about the worst oozing/stringing possible on this machine. In 3d printing, stringing is a common problem, especially with flexible materials. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings.

print quality - How to fix bad extrusion on my printer ... , Too Little And You Still Get The Effects Above.

end of print retraction problem? - Ultimaker 3D printers .... The extruder of a 3d printer is the mechanism that. We saw that retraction speed isn't going to resolve our problems and looking better at our tests it obvious that we need to get this parameter right. I've been having major problems with stringing on my sindoh 3dwox printer. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. I've been printing these blocks all morning long and still have issues. In 3d printing, stringing is a common problem, especially with flexible materials. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. A common problem encountered with plastic extrusion 3d printers is stripped filament. Following the first episode's success, i decided to keep going. So much more to come as the requests for assistance keep coming in :)if you have any 3d. To determine the optimal retraction values, you must first know the extruder you will be using and the material you will be printing with. This is because the most common aesthetic issues originate from. If you want flawless prints then you need to adjust properly your retraction settings. Overcome this issue with these 5 simple solutions. This represents about the worst oozing/stringing possible on this machine.