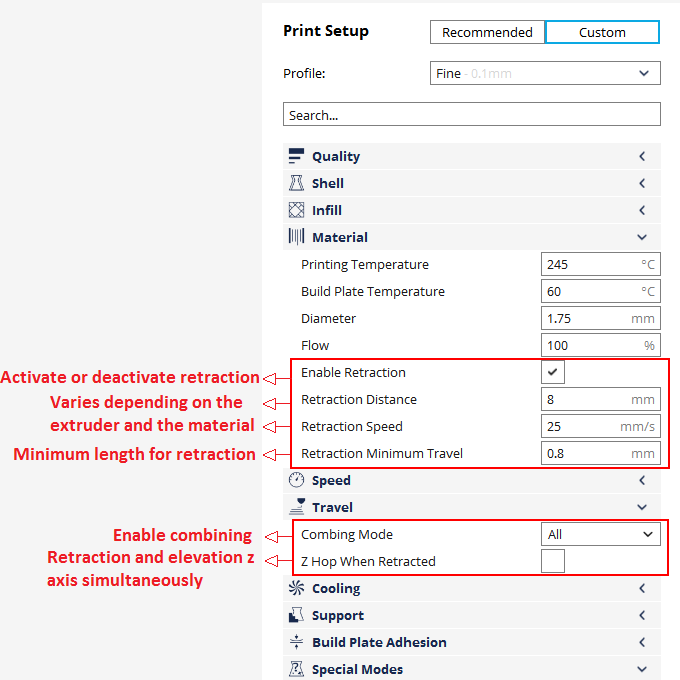

3D Printing Retraction Explained. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. The extruder of a 3d printer is the mechanism that. 3d printer retraction speed is one of three main retraction settings. Molten plastic is then layered to produce a model. Dialing in retraction helps you get the best possible part every time. It determines the speed at which the extruder retracts the filament. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Today, we cover retraction, a crucial part of basic tuning! While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. When your printer does not retract enough, visible oozing will occur as.

3D Printing Retraction Explained : We'll Explain How You Use It, Including What To Avoid.

3D Hubs on Twitter: "FDM 3D Printing explained in an easy .... Today, we cover retraction, a crucial part of basic tuning! Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Dialing in retraction helps you get the best possible part every time. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Molten plastic is then layered to produce a model. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. When your printer does not retract enough, visible oozing will occur as. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. 3d printer retraction speed is one of three main retraction settings. The extruder of a 3d printer is the mechanism that. It determines the speed at which the extruder retracts the filament.

By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing.

Dialing in retraction helps you get the best possible part every time. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Download files and build them with your 3d printer, laser cutter, or cnc. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Instead of generating extra e moves, the slicer just outputs. From there, you can specify the size and orientation for printing. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Could someone explain what all the different cura settings for retraction are? Guys in another forum explained how to fix it, but by that time i was already hooked on slic3r. This determines how fast the filament is retracted from the nozzle. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. Application of 3d printing technology in orthopedic. Today, we cover retraction, a crucial part of basic tuning! Historical perspectives, current usage, and future. Pla is very probably the most popular 3d printing filament around. Also this setup will retract a lot (as it should). Petg is notorious for creating strings and blobs, where finding the correct retraction values will help to minimize this. Entitled use of 3d printing in complex spinal surgery: The first is to allow the user to specify the extrusion multiplier for the solid infill layers. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Thingiverse is a universe of things. This 3d skin printer helps heal wounds and burns explained how 3d printing can be used to bioprint replacement skin for wound and burn victims as you can see in the video below. It determines the speed at which the extruder retracts the filament. Printed parts can have high dimensional accurately however if simplify3d implemented three additional settings. Molten filament extrusion is an inexact science at best. Suggested corrections place more coins on the platter when printing. Looking carefully at the printing process i can see that after a retraction there's a small amount of time the hotend isn't extruding plastic.

Retraction setting change? | E3D Online 3D Printing Forum : Both The Printer And Print Bed Are Properly Leveled.

Qu'est-ce que la rétraction en impression 3D? Définition .... Today, we cover retraction, a crucial part of basic tuning! While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Dialing in retraction helps you get the best possible part every time. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. It determines the speed at which the extruder retracts the filament. When your printer does not retract enough, visible oozing will occur as. Molten plastic is then layered to produce a model. The extruder of a 3d printer is the mechanism that. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. 3d printer retraction speed is one of three main retraction settings.

Cura settings explanation: retraction? : 3Dprinting | Free ... . How Does Retraction Work And When Should To Understand Retraction, We Must First Briefly Discuss What Extruders Are And How They Work.

Retraction Calibration - YouTube. When your printer does not retract enough, visible oozing will occur as. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. It determines the speed at which the extruder retracts the filament. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Dialing in retraction helps you get the best possible part every time. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. 3d printer retraction speed is one of three main retraction settings.

3D printing filament - Wikipedia : The nozzle will therefore print more objects and thus give the part more time to cool down before ironing.

10 Advanced 3D Slicer Settings That Will Save Your Prints!. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Dialing in retraction helps you get the best possible part every time. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. When your printer does not retract enough, visible oozing will occur as. Molten plastic is then layered to produce a model. The extruder of a 3d printer is the mechanism that. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. It determines the speed at which the extruder retracts the filament. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Today, we cover retraction, a crucial part of basic tuning! 3d printer retraction speed is one of three main retraction settings. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement.

3D Printing in Aerospace & Defense Industry - Detailed ... . The Extruder Of A 3D Printer Is The Mechanism That.

Retraction: Just say | 3d printing, Printing process .... 3d printer retraction speed is one of three main retraction settings. It determines the speed at which the extruder retracts the filament. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. The extruder of a 3d printer is the mechanism that. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Molten plastic is then layered to produce a model. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. Today, we cover retraction, a crucial part of basic tuning! While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Dialing in retraction helps you get the best possible part every time. When your printer does not retract enough, visible oozing will occur as.

3D printing process explained at the PROTIQ booth! - YouTube : Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

3D PRINTING EXPLAINED - YouTube. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Today, we cover retraction, a crucial part of basic tuning! It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. When your printer does not retract enough, visible oozing will occur as. 3d printer retraction speed is one of three main retraction settings. Molten plastic is then layered to produce a model. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. The extruder of a 3d printer is the mechanism that. Dialing in retraction helps you get the best possible part every time. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. It determines the speed at which the extruder retracts the filament.

3D Printing in Aerospace & Defense Industry - Detailed ... , Suggested Corrections Place More Coins On The Platter When Printing.

Retraction, A Powerful Setting Against Stringing - Best .... How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. 3d printer retraction speed is one of three main retraction settings. Today, we cover retraction, a crucial part of basic tuning! Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Molten plastic is then layered to produce a model. Dialing in retraction helps you get the best possible part every time. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. When your printer does not retract enough, visible oozing will occur as. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. It determines the speed at which the extruder retracts the filament. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. The extruder of a 3d printer is the mechanism that.

By understanding a little more about the 3D printing ... . Also Activate The 'Avoid Crossing Outline For Travel Movements' This Second Option It's Like Combing Of Cura.

TPE Filament: Durable, Elastic, and Versatile 3D Printing .... Today, we cover retraction, a crucial part of basic tuning! By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. When your printer does not retract enough, visible oozing will occur as. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. 3d printer retraction speed is one of three main retraction settings. Molten plastic is then layered to produce a model. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Dialing in retraction helps you get the best possible part every time. The extruder of a 3d printer is the mechanism that. It determines the speed at which the extruder retracts the filament. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work.

3D 프린터를 사용하게 되면, 맞닥뜨리게 되는 문제 중 하나가 바로, String 발생 문제 입니다 ... . Of Retraction In 3D Printing As It's A Very Important Parameter To Achieve Quality Prints, Without Material Depositions On The Exterior Face Of The Model, Or Retraction Is The Recoil Movement Of The Filament Necessary To Prevent Dripping Of Material During Movements And Displacements That The Vacuum.

3D Hubs on Twitter: "FDM 3D Printing explained in an easy .... 3d printer retraction speed is one of three main retraction settings. Dialing in retraction helps you get the best possible part every time. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. When your printer does not retract enough, visible oozing will occur as. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Molten plastic is then layered to produce a model. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. The extruder of a 3d printer is the mechanism that. Today, we cover retraction, a crucial part of basic tuning! It determines the speed at which the extruder retracts the filament. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement.

How 3D Printer works Explanation in Tamil language (3டி ... . Suggested Corrections Decrease Retraction Speed And Length When Printing.

Troubleshooting: Are your 3D Prints Stringing? Here's What .... By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Today, we cover retraction, a crucial part of basic tuning! The extruder of a 3d printer is the mechanism that. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Dialing in retraction helps you get the best possible part every time. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. 3d printer retraction speed is one of three main retraction settings. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Molten plastic is then layered to produce a model. When your printer does not retract enough, visible oozing will occur as. It determines the speed at which the extruder retracts the filament.

Stop the stringing with Retraction! 3D Printing 101 - YouTube : Retraction Is A Super Useful Setting You Can Use Within Your Slicer To Greatly Improve The Quality Of Your 3D Prints, But It's Very Misunderstood!

How do 3D printers work? - Explain that Stuff. Too much retraction results in little gaps, or even globbing due to air pockets within the print head. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Dialing in retraction helps you get the best possible part every time. It determines the speed at which the extruder retracts the filament. When your printer does not retract enough, visible oozing will occur as. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Molten plastic is then layered to produce a model. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. 3d printer retraction speed is one of three main retraction settings. How does retraction work and when should to understand retraction, we must first briefly discuss what extruders are and how they work. Retraction can easily be activated through your slicer software and can even be tweaked through a few settings. Today, we cover retraction, a crucial part of basic tuning! By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and all parts were printed with a skirt, but the skirt was removed for some of the pictures in order to more clearly visualize the oozing/stringing. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. The extruder of a 3d printer is the mechanism that.