3D Printing Process Types. When you purchase using a shopping link on our site we earn an affiliate commission. There are at least a half dozen distinct types of 3d printing. 3d printing is also known as additive manufacturing. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. They work by a process where a spool of. The process of printing includes several steps. Get it 3d printed for the best price using our 3d printing service marketplace! Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. In an additive process an object is created by laying down successive layers of material until the object is created. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates.

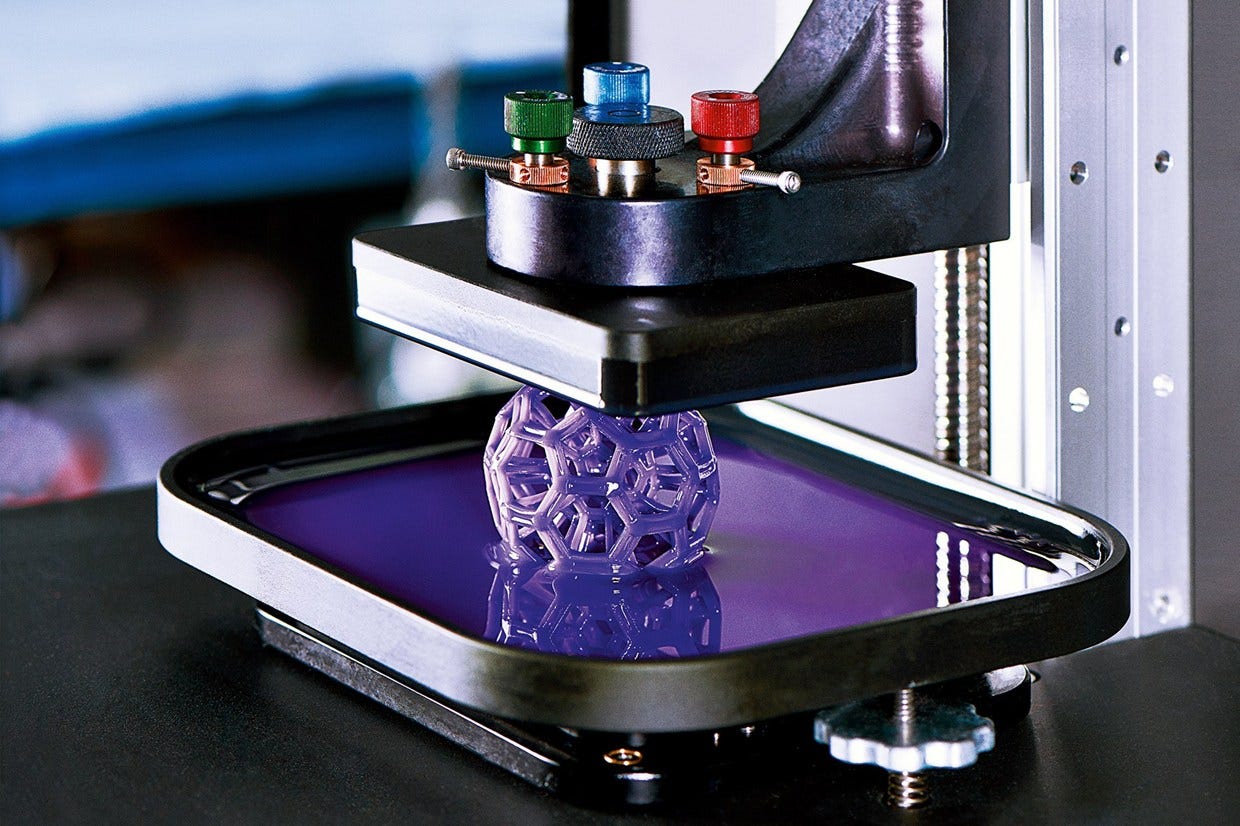

3D Printing Process Types : 3D Printing Is A Manufacturing Process That Creates A Three Dimensional Object By Incrementally Adding Material Until The Object Is Complete (This Stereolithography (Sla):

3D Printing Technology. Get it 3d printed for the best price using our 3d printing service marketplace! When you purchase using a shopping link on our site we earn an affiliate commission. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. The process of printing includes several steps. They work by a process where a spool of. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. In an additive process an object is created by laying down successive layers of material until the object is created. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. There are at least a half dozen distinct types of 3d printing. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. 3d printing is also known as additive manufacturing.

3d printing is a manufacturing process that creates a three dimensional object by incrementally adding material until the object is complete (this stereolithography (sla):

3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. In an additive process an object is created by laying down successive layers of material until the object is created. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Get it 3d printed for the best price using our 3d printing service marketplace! The process of printing includes several steps. Honestly i'm considering just packing the whole 3d printing thing in. Just by pressing a button, whatever you design will be made. Technically the first type of 3d printing to be invented back in the 1980s, sla beams a laser at a reactive liquid resin so it. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. There are also different types of 3d printing depending on the size, detail and scope of a project. Other manufacturing methods, like the there are a couple different types of 3d printing processes: The dlp technology was made in 1987 by larry hornbeck of texas instruments. Sls, dmls & slm (powder bed fusion). Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. The dlp technology was created in 1987 by larry hornbeck of how many types of 3d printers are there? is a question that generally keeps popping up in one's mind. The seven different types of 3d printers. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. Types of 3d printing processes. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Each different type of printer will vary slightly on how an object gets. This question gets harder to answer with. The iso/astm 52900 standard categorized all different types of 3d printing under one of these seven. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. Each distinct additive manufacturing approach has its positives, negatives, and overlap in the pp process, sections are printed first, like a waffle. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Digital light processing is another 3d printing process very similar to stereolithography. Because the process yields batch parts very quickly, it's being hailed as the technology that will propel 3d printing into mass production. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. Schematic representation of the 3d printing technique known as fused filament fabrication; 3d printing is also known as additive manufacturing. With so many printing techniques and types of 3d printing machines, there is bound to be confusion.

The 10 types of 3D Printing Technology - Future Today - Medium : Parts Built With 3D Printers Type Like This Usually Have Smooth Surfaces But Its Quality Very Depends On The Quality Of Sla Machine Used.

Types of 3D Printers: Complete Guide - SLA, DLP, FDM, SLS .... A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. Get it 3d printed for the best price using our 3d printing service marketplace! It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. The process of printing includes several steps. There are at least a half dozen distinct types of 3d printing. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. In an additive process an object is created by laying down successive layers of material until the object is created. When you purchase using a shopping link on our site we earn an affiliate commission. They work by a process where a spool of. 3d printing is also known as additive manufacturing. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion.

Learn how 3d printing metal works - Top 3 ways! | | 3d ... , Additive Manufacturing In An Umbrella Term Used To Describe Different Types Of Technologies Used To Create 3D Objects By The Process Of Layering The Raw Material Used.

Types of 3D printers or 3D printing technologies overview. 3d printing is also known as additive manufacturing. Get it 3d printed for the best price using our 3d printing service marketplace! When you purchase using a shopping link on our site we earn an affiliate commission. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. The process of printing includes several steps. In an additive process an object is created by laying down successive layers of material until the object is created. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates.

3D Printing technologies | 3d printing technology ... - Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines.

3D Printing - A 2014 Horizonwatching Trend Summary Report. When you purchase using a shopping link on our site we earn an affiliate commission. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Get it 3d printed for the best price using our 3d printing service marketplace! Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. There are at least a half dozen distinct types of 3d printing. In an additive process an object is created by laying down successive layers of material until the object is created. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. They work by a process where a spool of. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. 3d printing is also known as additive manufacturing. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. The process of printing includes several steps.

2019 3D Printing Technology Guide - 10 Types of 3D ... . Stacked Layers Of Material Form The Final 3D Printed Object.

Interactive Map of 3D Printing Tech Available. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. In an additive process an object is created by laying down successive layers of material until the object is created. When you purchase using a shopping link on our site we earn an affiliate commission. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. They work by a process where a spool of. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Get it 3d printed for the best price using our 3d printing service marketplace! There are at least a half dozen distinct types of 3d printing. 3d printing is also known as additive manufacturing. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. The process of printing includes several steps. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

3D Printing - A 2014 Horizonwatching Trend Summary Report . Because The Process Yields Batch Parts Very Quickly, It's Being Hailed As The Technology That Will Propel 3D Printing Into Mass Production.

Laser SLA vs DLP vs Masked SLA 3D Printing Technology .... The process of printing includes several steps. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. There are at least a half dozen distinct types of 3d printing. When you purchase using a shopping link on our site we earn an affiliate commission. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. In an additive process an object is created by laying down successive layers of material until the object is created. 3d printing is also known as additive manufacturing. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. Get it 3d printed for the best price using our 3d printing service marketplace! A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. They work by a process where a spool of. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Overwhelmed by the Amount of Processes and Materials ... - The Dlp Technology Was Created In 1987 By Larry Hornbeck Of How Many Types Of 3D Printers Are There? Is A Question That Generally Keeps Popping Up In One's Mind.

15 best The Types Of 3D Printing images on Pinterest .... They work by a process where a spool of. When you purchase using a shopping link on our site we earn an affiliate commission. There are at least a half dozen distinct types of 3d printing. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. In an additive process an object is created by laying down successive layers of material until the object is created. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. Get it 3d printed for the best price using our 3d printing service marketplace! The process of printing includes several steps. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing is also known as additive manufacturing.

Cladding (metalworking) - Wikipedia . Sls, Dmls & Slm (Powder Bed Fusion).

Mastering 3D Printing: Some Technical Insights in 2020 .... It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. They work by a process where a spool of. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. In an additive process an object is created by laying down successive layers of material until the object is created. The process of printing includes several steps. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. 3d printing is also known as additive manufacturing. When you purchase using a shopping link on our site we earn an affiliate commission. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. There are at least a half dozen distinct types of 3d printing. Get it 3d printed for the best price using our 3d printing service marketplace! Ok, so printers, printing materials, printed objects, and 3d printing software can all vary.

3D printing is also called as additive manufacturing. It ... : Schematic Representation Of The 3D Printing Technique Known As Fused Filament Fabrication;

Metal 3D Printing: An Overview of the Most Common Types .... There are at least a half dozen distinct types of 3d printing. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. The process of printing includes several steps. They work by a process where a spool of. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing is also known as additive manufacturing. In an additive process an object is created by laying down successive layers of material until the object is created. Get it 3d printed for the best price using our 3d printing service marketplace! When you purchase using a shopping link on our site we earn an affiliate commission. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time.

Lasers for 3D Printing: Additive manufacturing with NIR ... , Additive Manufacturing In An Umbrella Term Used To Describe Different Types Of Technologies Used To Create 3D Objects By The Process Of Layering The Raw Material Used.

18 3D Printer Filament Types And Uses Comparison Guide .... Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. There are at least a half dozen distinct types of 3d printing. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. When you purchase using a shopping link on our site we earn an affiliate commission. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. In an additive process an object is created by laying down successive layers of material until the object is created. They work by a process where a spool of. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. The process of printing includes several steps. 3d printing is also known as additive manufacturing. Get it 3d printed for the best price using our 3d printing service marketplace!

3D Printing | Office of Distance Education and eLearning : With The Evolution Of The Trend, 3D Printing Has Become A Applied In Clinical Research, Represented By Three Types Of Medical Device Implants, The Need For Clinical, Process And Other Aspects Of Data.

How to choose the best 3D Printer - A buyer's guide. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping let's first discuss how 3d printing fits within the product development cycle and then take a look at common types of 3d printing technologies and. They work by a process where a spool of. Yet despite this, the process from design to end product before we begin to look at the various 3d printer types and printing practices, we'll take a moment to list the main components of these machines. A precise process, material jetting is one of the most expensive 3d printing methods, and the parts tend to be brittle and will degrade over time. It starts from creation of 3d model in cad program, special piece of software processes the cad model and generates. The process of printing includes several steps. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. There are at least a half dozen distinct types of 3d printing. Sometimes called fused filament fabrication (fff) is a 3d printing technology that uses a process called material extrusion. Get it 3d printed for the best price using our 3d printing service marketplace! 3d printing is also known as additive manufacturing. In an additive process an object is created by laying down successive layers of material until the object is created. Parts built with 3d printers type like this usually have smooth surfaces but its quality very depends on the quality of sla machine used. When you purchase using a shopping link on our site we earn an affiliate commission.