3D Printing Plastic Vs Metal. Some of these plastic materials are in the form of filament spool. Cad design differences betweeen plastic and metal 3d printing. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Most engineers and designers choose metals to. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. Fdm technology is known for using plastic materials in 3d printing. Making friends with the enemy. Plastic does not conduct heat like metal. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. 3d printing with metals offers an unique combination of practical and aesthetic properties. A quick search of google powderized metal has even been used to make medical devices. When metal dust is used for 3d printing, the process allows for a reduced number. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal casting and 3d printing: Metal 3d printing vs metal casting:

3D Printing Plastic Vs Metal , Additive Manufacturing Doesn't Necessarily Another Way Of Combining Additive Manufacturing And Classical Metal Casting Is To 3D Print Plastic Copies Of The Final Product.

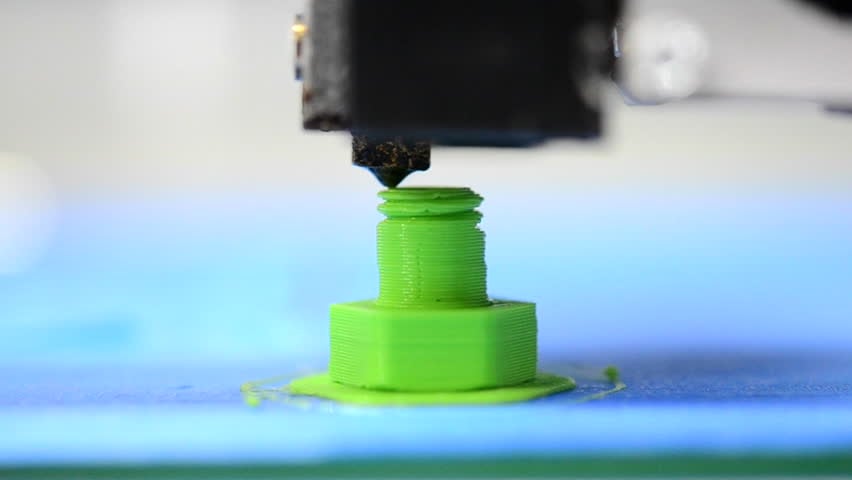

3D Printing Services - FDM | SLA | SLS | DMLS - 3D Print .... Fdm technology is known for using plastic materials in 3d printing. 3d printing with metals offers an unique combination of practical and aesthetic properties. Metal 3d printing vs metal casting: Most engineers and designers choose metals to. Some of these plastic materials are in the form of filament spool. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Making friends with the enemy. Plastic does not conduct heat like metal. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. Cad design differences betweeen plastic and metal 3d printing. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. When metal dust is used for 3d printing, the process allows for a reduced number. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal casting and 3d printing: A quick search of google powderized metal has even been used to make medical devices.

There are many types of filament available with different properties, requiring different temperatures to print.

Metal filaments are made of very finely ground metals combined with pla and a polymer glue. Cad design differences betweeen plastic and metal 3d printing. Making friends with the enemy. Uses the same process as sls but is used when referring to the process of sintering metal alloys vs. Metal 3d printing vs metal casting: Most 3d printers use additive processes to create products from specialized plastics, resins, metals, and other materials. These are printed directly by binding metal dust and firing it to become a hard part. Filament is commonly available in the two standard diameters of 1.75 mm and 2.85 mm. When metal dust is used for 3d printing, the process allows for a reduced number. Metal filaments are made of very finely ground metals combined with pla and a polymer glue. However, one company has recognised the potential of the technology for metal 3d. As a result of the unique materials used for the printing process, 3d parts usually do not have the necessary strength for use in demanding settings including airplanes, vehicles. Cnc and metal 3d printing can be combined to manufacture parts with both organic shape and very tight tolerances at the critical locations. Two or more metals mixed together, generally done to make the metal stronger. We walk you through the steps of 3d printing metal. Find out how 3d printing metal works and how you can create designs infused with metal powder! Every metal 3d printer will generally fall into one of these four categories (with a few exceptions that will be covered at the end): 3d printing with metals offers an unique combination of practical and aesthetic properties. Powder bed fusion, binder jetting, direct energy deposition, and material extrusion. The use of 3d printing in innovative and experimental scenarios has been grabbing recent headlines, but the reality is that the majority of today's plastic parts are manufactured using plastic injection molding. Plastic does not conduct heat like metal. Acrylonitrile butadiene it is similar to the material used in biodegradable plastic packaging and melts at between 180 and what it is: Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. With many metals having a melting point greater than 500° c or 1,000° f, metal 3d printers are expensive and potentially sculpteo, a 3d printing service bureau, prints in ceramic with a z corp 3d printer. 3d printing, plastics, and metallurgy. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Fdm technology is known for using plastic materials in 3d printing. Start studying 3d printing, plastics, and metallurgy. 3d printing allows circuits and batteries to be built into plastic parts used to make devices. Direct metal laser sintering (dmls):

Snapmaker : The All-Metal 3D Printer by Snapmaker —Kickstarter : Some Of These Plastic Materials Are In The Form Of Filament Spool.

6 Advantages of 3d printing vs injection molding -3D .... Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Plastic does not conduct heat like metal. When metal dust is used for 3d printing, the process allows for a reduced number. Fdm technology is known for using plastic materials in 3d printing. Some of these plastic materials are in the form of filament spool. Metal casting and 3d printing: Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Making friends with the enemy. A quick search of google powderized metal has even been used to make medical devices. Cad design differences betweeen plastic and metal 3d printing. Metal 3d printing vs metal casting: 3d printing with metals offers an unique combination of practical and aesthetic properties. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Most engineers and designers choose metals to. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes.

PLA vs ABS 3D Printing Plastic - What's the difference? - Two Or More Metals Mixed Together, Generally Done To Make The Metal Stronger.

Sterling Silver 3D Printing Material Information - Shapeways. Metal casting and 3d printing: Some of these plastic materials are in the form of filament spool. Cad design differences betweeen plastic and metal 3d printing. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. 3d printing with metals offers an unique combination of practical and aesthetic properties. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Most engineers and designers choose metals to. Fdm technology is known for using plastic materials in 3d printing. Metal 3d printing vs metal casting:

20x #2 2-56 Long Brass Threaded Heat Set Inserts for ... - Some of these plastic materials are in the form of filament spool.

Stratasys Objet1000 Plus review - 3D printer. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Fdm technology is known for using plastic materials in 3d printing. Cad design differences betweeen plastic and metal 3d printing. When metal dust is used for 3d printing, the process allows for a reduced number. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal casting and 3d printing: Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Metal 3d printing vs metal casting: Most engineers and designers choose metals to. A quick search of google powderized metal has even been used to make medical devices. Plastic does not conduct heat like metal. Making friends with the enemy. 3d printing with metals offers an unique combination of practical and aesthetic properties. Some of these plastic materials are in the form of filament spool.

FDM vs SLA Printing Technology - How Does 3D Printing ... , Plastic Does Not Conduct Heat Like Metal.

Top Considerations for Using Metal 3D Printing vs. CNC .... When metal dust is used for 3d printing, the process allows for a reduced number. Some of these plastic materials are in the form of filament spool. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal 3d printing vs metal casting: Most engineers and designers choose metals to. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Fdm technology is known for using plastic materials in 3d printing. Cad design differences betweeen plastic and metal 3d printing. Metal casting and 3d printing: Plastic does not conduct heat like metal. A quick search of google powderized metal has even been used to make medical devices. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Making friends with the enemy. 3d printing with metals offers an unique combination of practical and aesthetic properties.

Formlabs Clear versus Shapeways FUD — a comparison | my ... , When Metal Dust Is Used For 3D Printing, The Process Allows For A Reduced Number.

3D Printing Goes Metal: European Space Agency Shows Off .... Cad design differences betweeen plastic and metal 3d printing. 3d printing with metals offers an unique combination of practical and aesthetic properties. Metal 3d printing vs metal casting: Most engineers and designers choose metals to. Some of these plastic materials are in the form of filament spool. When metal dust is used for 3d printing, the process allows for a reduced number. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. A quick search of google powderized metal has even been used to make medical devices. Metal casting and 3d printing: If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Fdm technology is known for using plastic materials in 3d printing. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. Making friends with the enemy. Plastic does not conduct heat like metal. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed.

SLA,SLS,SLM 3D printing,Metal plastic Rapid prototype ... , A Print Made With Abs Filament By The M3D Micro Printer.

3D printing versus injection molding - Make Parts Fast. 3d printing with metals offers an unique combination of practical and aesthetic properties. Metal casting and 3d printing: If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Most engineers and designers choose metals to. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal 3d printing vs metal casting: A quick search of google powderized metal has even been used to make medical devices. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. Some of these plastic materials are in the form of filament spool. When metal dust is used for 3d printing, the process allows for a reduced number. Fdm technology is known for using plastic materials in 3d printing. Making friends with the enemy. Cad design differences betweeen plastic and metal 3d printing. Plastic does not conduct heat like metal. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product.

Ningbo Industrial Grade 3d Printing Service Transparent ... - Start Studying 3D Printing, Plastics, And Metallurgy.

3D Printing Filament - PLA vs ABS: How to Choose the Right One. Making friends with the enemy. Plastic does not conduct heat like metal. 3d printing with metals offers an unique combination of practical and aesthetic properties. A quick search of google powderized metal has even been used to make medical devices. Metal 3d printing vs metal casting: Some of these plastic materials are in the form of filament spool. Fdm technology is known for using plastic materials in 3d printing. Cad design differences betweeen plastic and metal 3d printing. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Most engineers and designers choose metals to. Metal casting and 3d printing: When metal dust is used for 3d printing, the process allows for a reduced number. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes.

Flat / V Type Plastic/Stainless Steel Pulley Concave Idler ... . Cnc And Metal 3D Printing Can Be Combined To Manufacture Parts With Both Organic Shape And Very Tight Tolerances At The Critical Locations.

The Differences Between Metal vs. Plastic 3D Printing .... A quick search of google powderized metal has even been used to make medical devices. Plastic does not conduct heat like metal. Cad design differences betweeen plastic and metal 3d printing. When metal dust is used for 3d printing, the process allows for a reduced number. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal casting and 3d printing: Most engineers and designers choose metals to. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Making friends with the enemy. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Some of these plastic materials are in the form of filament spool. 3d printing with metals offers an unique combination of practical and aesthetic properties. Metal 3d printing vs metal casting: Fdm technology is known for using plastic materials in 3d printing. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes.

SLA,SLS,SLM 3D printing,Metal plastic Rapid prototype ... , Uses The Same Process As Sls But Is Used When Referring To The Process Of Sintering Metal Alloys Vs.

3D printing vs. CNC machining | 3D Hubs. If a certain area on a plastic part gets too hot during printing it simply melts and that's it. Plastic does not conduct heat like metal. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. When metal dust is used for 3d printing, the process allows for a reduced number. Making friends with the enemy. Some of these plastic materials are in the form of filament spool. Most engineers and designers choose metals to. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Metal casting and 3d printing: Metal 3d printing vs metal casting: Fdm technology is known for using plastic materials in 3d printing. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes. A quick search of google powderized metal has even been used to make medical devices. Cad design differences betweeen plastic and metal 3d printing. 3d printing with metals offers an unique combination of practical and aesthetic properties.

Formlabs Clear versus Shapeways FUD — a comparison | my ... : A Print Made With Abs Filament By The M3D Micro Printer.

Flat / V Type Plastic/Stainless Steel Pulley Concave Idler .... Metal 3d printing vs metal casting: If a certain area on a plastic part gets too hot during printing it simply melts and that's it. When metal dust is used for 3d printing, the process allows for a reduced number. Making friends with the enemy. Metal casting and 3d printing: A quick search of google powderized metal has even been used to make medical devices. Plastic items made in 3d printers come in a variety of shapes and consistencies, from flat and round to grooved and meshed. Most engineers and designers choose metals to. Plastic does not conduct heat like metal. Some of these plastic materials are in the form of filament spool. 3d printing with metals offers an unique combination of practical and aesthetic properties. Fdm technology is known for using plastic materials in 3d printing. Cad design differences betweeen plastic and metal 3d printing. Additive manufacturing doesn't necessarily another way of combining additive manufacturing and classical metal casting is to 3d print plastic copies of the final product. Not so with metal, which readily conducts heat and that can affect the rest of the part with sometimes.