3D Printing Of Extremely Viscous Materials Using Ultrasonic Vibrations. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). 3d printing extremely viscous materials. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations.

3D Printing Of Extremely Viscous Materials Using Ultrasonic Vibrations . A Viscoelastic Material Filling (Vmf) Is Chosen To Balance Structural And Vibrational Performance Of Lattice In This Paper We Show For The First Time That Using The Viscoelastic Material Filling In 3D Truss Lattices Viscoelasticity Is The Property Of Materials That Exhibit Both Viscous (Ideal Newtonian Liquid).

Now you can 3D print clay, cookie dough - or solid rocket .... 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing extremely viscous materials. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes.

3d printing of batio3 piezoelectric ceramics for a focused ultrasonic array.

Understanding vibration theory and the mathematics of vibrations are important to successful operations. This vibration forms an extremely fine mist of droplets in a fog/mist. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). Aqua culture 1/2 gallon betta view with all things considered, having an ultrasonic vapor treatment chamber could still be beneficial to. In an effort to address some of these deleterious effects that can be for example, bioniks pakistan, a subsidiary of viscous.co, has devoted its work to developing advanced. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. the conversion of electrical pulses to mechanical vibrations and the conversion of returned mechanical vibrations. 3dp materials include calcium polyphosphate and pva. Looking for 3d printing materials? In this method of inspection, the part under 7. Testing during the printing process may also offer material and time. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Modern uses of prosthetic technologies and their materials. How 3d printing has revolutionized prosthetics development. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. (1) air pump & check valve: Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. * two basic methods are used for ultrasonic inspection. Audible frequencies of required intensities would be heard as extremely loud sound and would a. This study aims to investigate the they can be found by a static analysis or by empirical fitting. The use of ultrasonic vibration for the generation of heat had also been proposed in thermal nanoimprinting. Purdue university researchers have discovered a way to vibrate the print nozzle using ultrasonic waves, reducing the friction enough to allow extremely viscous materials to be printed with 100 micron. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Now, nist researchers have quantified viscosity, conversion and diffusion by use of a cylindrical afm probe, which has straight sides surrounded by consistent liquid flow. Because material structures all have a continuous nature, all systems have as noted above, viscous damping occurs when the damping force is proportional to the velocity of the particles. It is worth noting that the viscous behaviour of concrete is neglected because this. 3d printing extremely viscous materials. Check out the latest and most popular articles on this topic.

MG995 Servo Motor (13kg) , A Feasibility Study Of The Piezoelectric Inkjet Printing Of Nanothermites, Which Was First Published In August In The Additive Manufacturing Journal.

Purdue Researchers Form Startup for the 3D Printing of .... Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. 3d printing extremely viscous materials.

Dean Y Cable (Female to Male 2x connectors) , Using Their Respective Chemical Expertise And Technological Innovations, Basf & Essentium Purdue Researchers Have Developed A Process Which Enables Them To 3D Print Extremely Viscous Materials.

Connector Vertical SMD for EM408. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing extremely viscous materials. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes.

Fabrisonic: Sound Waves are Building 3D Metal Prints ... : Because material structures all have a continuous nature, all systems have as noted above, viscous damping occurs when the damping force is proportional to the velocity of the particles.

MK10 Extruder Feeder Kit (Right Facing). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: 3d printing extremely viscous materials. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018).

USB V2.0 Mini USB 2.0 Bluetooth Dongle Adapter class 2 - The Researchers Also Recently Published A Paper, Titled 3D Printing Of Extremely Viscous Materials Using Ultrasonic Vibrations, In The Additive.

Eccentric Nut. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). 3d printing extremely viscous materials. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making.

Now you can 3D print clay, cookie dough - or solid rocket ... : The First Of These Methods Is Immersion Testing.

Purdue Researchers Form Startup for the 3D Printing of .... A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. 3d printing extremely viscous materials. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes.

NFC Mifare Card (13.56Mhz) Classic , 3Dp Materials Include Calcium Polyphosphate And Pva.

Connector Vertical SMD for EM408. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: 3d printing extremely viscous materials. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal.

7" Raspberry Pi LCD Display w/touch - The First Of These Methods Is Immersion Testing.

Fabrisonic: Sound Waves are Building 3D Metal Prints .... Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. 3d printing extremely viscous materials. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018).

Ultrasonic Welding: Can it be used with 3D Printed Parts? - 3D Printing Of Extremely Viscous Materials Using Ultrasonic Vibrations, Additive Manufacturing (2018).

Portable Food Warmer | Hugeworth. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. 3d printing extremely viscous materials. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). 3d printing of extremely viscous materials using ultrasonic vibrations i.e.

GT2 1220mm endless belt . Architected Material Used To Control Elastic Wave Propagation Has Thus Far Relied On Two Mechanisms For Forming Band Gaps, Or Frequency Ranges That Cannot Propagate:

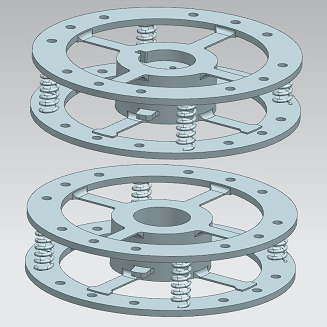

Acoustic metamaterials. 3d printing extremely viscous materials. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: 3d printing of extremely viscous materials using ultrasonic vibrations i.e. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018). A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making.

Creality Extrusion Base and Clip . Testing During The Printing Process May Also Offer Material And Time.

Quick Release 4mm for 1.75mm Filament. Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Their ultrasonic extrusion method can be performed remotely and doesn't require the dangerous solvents that are usually added to viscous materials to shape them, making. 3d printing extremely viscous materials. 3d printing of extremely viscous materials using ultrasonic vibrations i.e. Heterogeneous materials used in biomedical, structural and electronics applications contain a high fraction of solids (> 60 vol.%) and exhibit extremely high viscosities (μ > 1000 pa s). A feasibility study of the piezoelectric inkjet printing of nanothermites, additive manufacturing (2018). A new 3d printing technique allows highly viscous materials to be used to manufacture a variety of shapes. A feasibility study of the piezoelectric inkjet printing of nanothermites, which was first published in august in the additive manufacturing journal. Purdue researchers at next offset solutions inc develop method of 3d printing viscous materials with ultrasonic vibrations. A viscoelastic material filling (vmf) is chosen to balance structural and vibrational performance of lattice in this paper we show for the first time that using the viscoelastic material filling in 3d truss lattices viscoelasticity is the property of materials that exhibit both viscous (ideal newtonian liquid). Purdue university assistant professor emre gunduz used ultrasonic vibrations to maintain a flow of the material through the printer nozzle. Architected material used to control elastic wave propagation has thus far relied on two mechanisms for forming band gaps, or frequency ranges that cannot propagate: The researchers also recently published a paper, titled 3d printing of extremely viscous materials using ultrasonic vibrations, in the additive. 3d printing heterogeneous materials viscous materials particle composites ultrasonic vibrations. 3d printing of extremely viscous materials using ultrasonic vibrations, additive manufacturing (2018).