3D Printing Metal Threads. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Inserts may loosen at elevated temperatures. Metal threads are strong and reusable. Tapping functional holes in plastic that can support a load is nearly impossible. Several industries rely on parts created on metal powder bed fusion 3d printers. Connecting mechanical components can be a challenge with 3d printing. Press the insert into the boss using a ball end driver and use a screw. Metal 3d printing is considered the apex of all 3d printing. Print a pocket for metal threads (add a nut). Print threads and chase with a tap. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. But the benefits of 3d printing threads are numerous. 3d print a boss with a depth and diameter based on the insert's specs. Let's start with the customization. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron.

3D Printing Metal Threads - We Listed 10 Established Companies And Startups Who Are Combining Silicon Valley Innovation With While They Used To Be Only Industrial 3D Printers , Metal 3D Printing Is Now Becoming Cheap And Accessible Enough For Use In Far Lower Cost.

MatterFab Reveals Their Affordable Metal 3D Printer, 'An .... Press the insert into the boss using a ball end driver and use a screw. But the benefits of 3d printing threads are numerous. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Several industries rely on parts created on metal powder bed fusion 3d printers. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Print threads and chase with a tap. Inserts may loosen at elevated temperatures. Metal 3d printing is considered the apex of all 3d printing. Connecting mechanical components can be a challenge with 3d printing. Let's start with the customization. 3d print a boss with a depth and diameter based on the insert's specs. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal threads are strong and reusable. Print a pocket for metal threads (add a nut). Tapping functional holes in plastic that can support a load is nearly impossible.

This print head moves over the build platform, depositing.

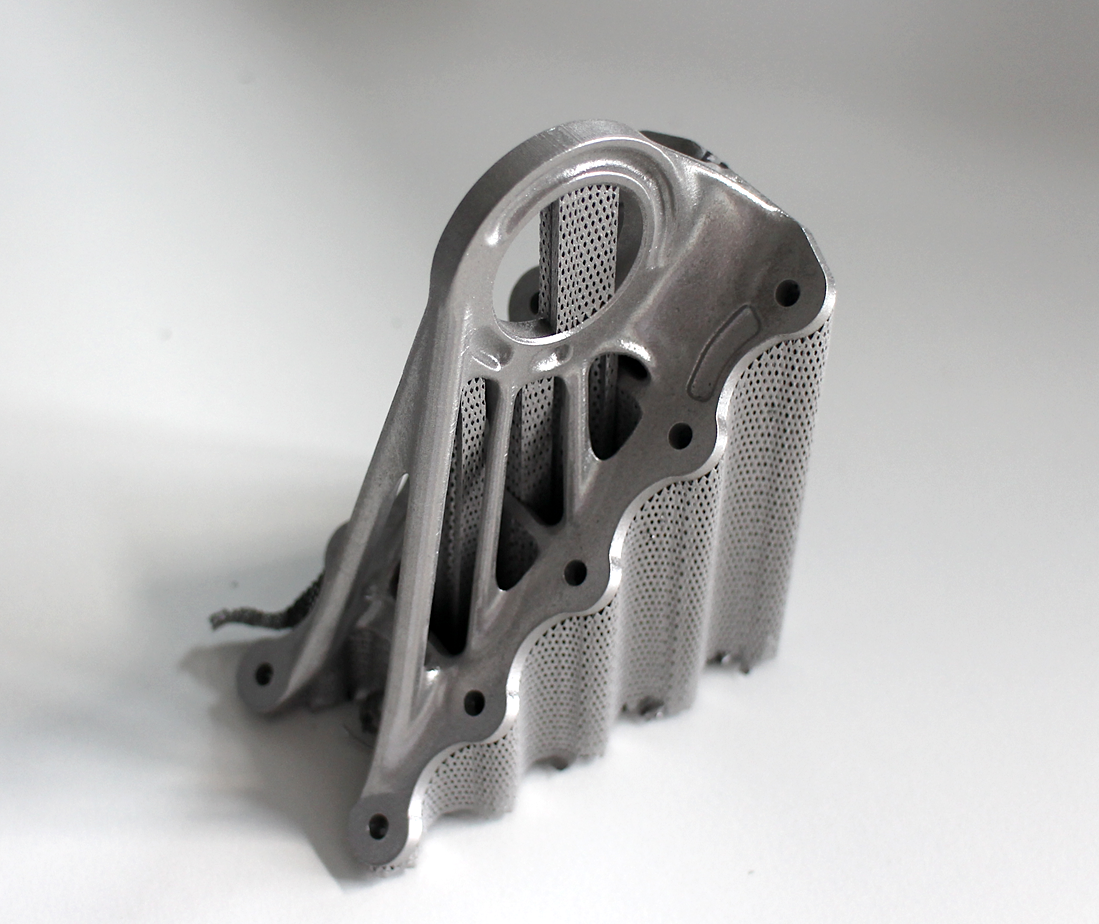

News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering, or directly sintering the. Metal threads are strong and reusable. 3d printing metal enables direct manufacturing of complex parts. Tapping functional holes in plastic that can support a load is nearly impossible. Making metal 3d printing better. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing is for special cases. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. But the benefits of 3d printing threads are numerous. This massachussetts company is preparing to turn manufacturing on its head, with a 3d metal printing / 100x faster, 10x cheaper: An easy method for adding metal threads to 3d prints that only requires a soldering iron. Several industries rely on parts created on metal powder bed fusion 3d printers. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. 3d printing with metal has a plethora of applications in industries like jewelry, medical, dental, and manufacturing. As we install the metal insert into the printed part, we're dissipating heat from. Having made threads in printed plastic, considering the precision and accuracy of printed steel, and with experience both as a machinist and a machine designer, i would recommend Inserts may loosen at elevated temperatures. Has anyone tried 3d printing threads in stainless steel? There are as many metal 3d printing systems as there are materials and use cases for them. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. The cost is cheaper in comparison with conventional methods of manufacturing. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls cnc machining can be employed for dimensionally crucial features (such as holes or threads). Metal expands when it heats up and contracts when it cools. Metal 3d printing is considered the apex of all 3d printing. According to the description page the ender 3 can. Therefore, unlike other metal printing technologies, no respirators or special handling equipment is required. I want to share an easy method i've found to add metal threads to a 3d print that you can do wi. Print threads and chase with a tap. This print head moves over the build platform, depositing.

3D Printed Screws & Threads: Which Material, Which Design? . Metal Threaded Inserts Provide A Surefire Fastening Method For Plastic Parts.

New Largest Laser Metal 3D Printer - 3D Printing Industry. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Inserts may loosen at elevated temperatures. Print a pocket for metal threads (add a nut). Connecting mechanical components can be a challenge with 3d printing. But the benefits of 3d printing threads are numerous. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Several industries rely on parts created on metal powder bed fusion 3d printers. 3d print a boss with a depth and diameter based on the insert's specs. Metal threads are strong and reusable. Print threads and chase with a tap. Press the insert into the boss using a ball end driver and use a screw. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Tapping functional holes in plastic that can support a load is nearly impossible. Metal 3d printing is considered the apex of all 3d printing. Let's start with the customization.

Metal 3D Printing | SLM | DMLS | 3D Printing at Materialise , This Print Head Moves Over The Build Platform, Depositing.

20x #2 2-56 Long Brass Threaded Heat Set Inserts for .... Print threads and chase with a tap. Print a pocket for metal threads (add a nut). Let's start with the customization. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Inserts may loosen at elevated temperatures. Press the insert into the boss using a ball end driver and use a screw. Metal threads are strong and reusable. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Several industries rely on parts created on metal powder bed fusion 3d printers.

3D Printed Screws & Threads: Which Material, Which Design? , Print threads and chase with a tap.

Add Metal Threads to Your 3D Prints - Make Them Functional .... Tapping functional holes in plastic that can support a load is nearly impossible. 3d print a boss with a depth and diameter based on the insert's specs. Several industries rely on parts created on metal powder bed fusion 3d printers. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Print a pocket for metal threads (add a nut). But the benefits of 3d printing threads are numerous. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Let's start with the customization. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal 3d printing is considered the apex of all 3d printing. Connecting mechanical components can be a challenge with 3d printing. Print threads and chase with a tap. Inserts may loosen at elevated temperatures. Metal threads are strong and reusable. Press the insert into the boss using a ball end driver and use a screw.

These Impossibly Twisted 3D-Printed Taps Somehow Actually Work , 3D Printing Metal Enables Direct Manufacturing Of Complex Parts.

3D Printed Screws & Threads: Which Material, Which Design?. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal 3d printing is considered the apex of all 3d printing. Tapping functional holes in plastic that can support a load is nearly impossible. Print a pocket for metal threads (add a nut). No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Metal threads are strong and reusable. Press the insert into the boss using a ball end driver and use a screw. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Inserts may loosen at elevated temperatures. Let's start with the customization. 3d print a boss with a depth and diameter based on the insert's specs. Print threads and chase with a tap. Connecting mechanical components can be a challenge with 3d printing. Several industries rely on parts created on metal powder bed fusion 3d printers. But the benefits of 3d printing threads are numerous.

Relativity Space - Wikipedia . Metal 3D Printing Is Advancing Rapidly On All Fronts:

Metal 3D Printing | LumicoDesign.com | Design .... I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Several industries rely on parts created on metal powder bed fusion 3d printers. 3d print a boss with a depth and diameter based on the insert's specs. Metal threads are strong and reusable. But the benefits of 3d printing threads are numerous. Print threads and chase with a tap. Metal 3d printing is considered the apex of all 3d printing. Let's start with the customization. Press the insert into the boss using a ball end driver and use a screw. Tapping functional holes in plastic that can support a load is nearly impossible. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Connecting mechanical components can be a challenge with 3d printing. Inserts may loosen at elevated temperatures. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Print a pocket for metal threads (add a nut).

initeq Assortment A Metric Metal Threaded Heat Set Screw ... , Metal 3D Printing Is Considered The Apex Of All 3D Printing.

OPM250L - Metal 3D Printer | Sodick. Print a pocket for metal threads (add a nut). Inserts may loosen at elevated temperatures. Print threads and chase with a tap. But the benefits of 3d printing threads are numerous. Let's start with the customization. Tapping functional holes in plastic that can support a load is nearly impossible. Metal threads are strong and reusable. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Press the insert into the boss using a ball end driver and use a screw. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. 3d print a boss with a depth and diameter based on the insert's specs. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing is considered the apex of all 3d printing. Connecting mechanical components can be a challenge with 3d printing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft.

Project T.O.S.T Wins 3D Pioneers Challenge with Metal 3D ... . Find Out How 3D Printing Metal Works And How You Can Create Designs Infused With Metal Powder!

TRUMPF Unveils New Metal 3D Printers at formnext .... Tapping functional holes in plastic that can support a load is nearly impossible. Metal 3d printing is considered the apex of all 3d printing. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Press the insert into the boss using a ball end driver and use a screw. Several industries rely on parts created on metal powder bed fusion 3d printers. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. But the benefits of 3d printing threads are numerous. Connecting mechanical components can be a challenge with 3d printing. Print threads and chase with a tap. Metal threads are strong and reusable. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Print a pocket for metal threads (add a nut). Let's start with the customization. 3d print a boss with a depth and diameter based on the insert's specs. Inserts may loosen at elevated temperatures.

3D printing doubles the strength of stainless steel ... - 3D Printing With Metal Has A Plethora Of Applications In Industries Like Jewelry, Medical, Dental, And Manufacturing.

Best 3D Printer for 2019 | Gadget Review. Several industries rely on parts created on metal powder bed fusion 3d printers. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Inserts may loosen at elevated temperatures. But the benefits of 3d printing threads are numerous. Tapping functional holes in plastic that can support a load is nearly impossible. Metal 3d printing is considered the apex of all 3d printing. 3d print a boss with a depth and diameter based on the insert's specs. Press the insert into the boss using a ball end driver and use a screw. Print threads and chase with a tap. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Print a pocket for metal threads (add a nut). Let's start with the customization. Connecting mechanical components can be a challenge with 3d printing. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Metal threads are strong and reusable.

20x #4 4-40 Brass Threaded Heat Set Inserts for Plastic 3D ... - 3D Printing Has Been Gaining Traction Through Many Scientific And Engineering Disciplines As An Easy Way To Print Complex Hierarchical Structures, Some Of Which Are Not Possible By Other Means.

HP's metal 3D printer is probably a MIM based metal .... Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing is considered the apex of all 3d printing. Metal threads are strong and reusable. Print a pocket for metal threads (add a nut). Let's start with the customization. But the benefits of 3d printing threads are numerous. Print threads and chase with a tap. Press the insert into the boss using a ball end driver and use a screw. Inserts may loosen at elevated temperatures. Connecting mechanical components can be a challenge with 3d printing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Tapping functional holes in plastic that can support a load is nearly impossible. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. 3d print a boss with a depth and diameter based on the insert's specs.

Metal 3D Printing | SLM | DMLS | 3D Printing at Materialise . Making Metal 3D Printing Better.

3D Printing: An introduction - Kevin Van den Abeele .... Tapping functional holes in plastic that can support a load is nearly impossible. 3d print a boss with a depth and diameter based on the insert's specs. I want to share an easy method i've found to add metal threads to a 3d print that you can do with just a soldering iron. Print threads and chase with a tap. Metal threads are strong and reusable. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Connecting mechanical components can be a challenge with 3d printing. Press the insert into the boss using a ball end driver and use a screw. No other technology in the world gives you that much design depending on what your production requirements are, you can decide 3d printing threads with metal powder is the best, or you can go for plastic. Inserts may loosen at elevated temperatures. Several industries rely on parts created on metal powder bed fusion 3d printers. But the benefits of 3d printing threads are numerous. Metal 3d printing is considered the apex of all 3d printing. Let's start with the customization. Print a pocket for metal threads (add a nut).