3D Printing Metal Explained. Metal 3d printing is considered the apex of all 3d printing. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing is for special cases. Metal 3d printing with the desktop metal studio system. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Several industries rely on parts created on metal powder bed fusion 3d printers. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. The cost is cheaper in comparison with conventional methods of manufacturing. This print head moves over the build platform, depositing. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. The benefits of metal 3d printing are manifold. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal 3d printing walkthrough | markforged metal x. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means.

3D Printing Metal Explained . We Walk You Through The Steps Of 3D Printing Metal.

Desktop Metal Studio 3D Printer | Affordable Metal 3D Printing. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing is for special cases. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. The cost is cheaper in comparison with conventional methods of manufacturing. Metal 3d printing with the desktop metal studio system. Metal 3d printing is advancing rapidly on all fronts: The benefits of metal 3d printing are manifold. Metal 3d printing is considered the apex of all 3d printing. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing walkthrough | markforged metal x. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. This print head moves over the build platform, depositing. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers:

The term 3d printing can refer to a variety of processes in which.

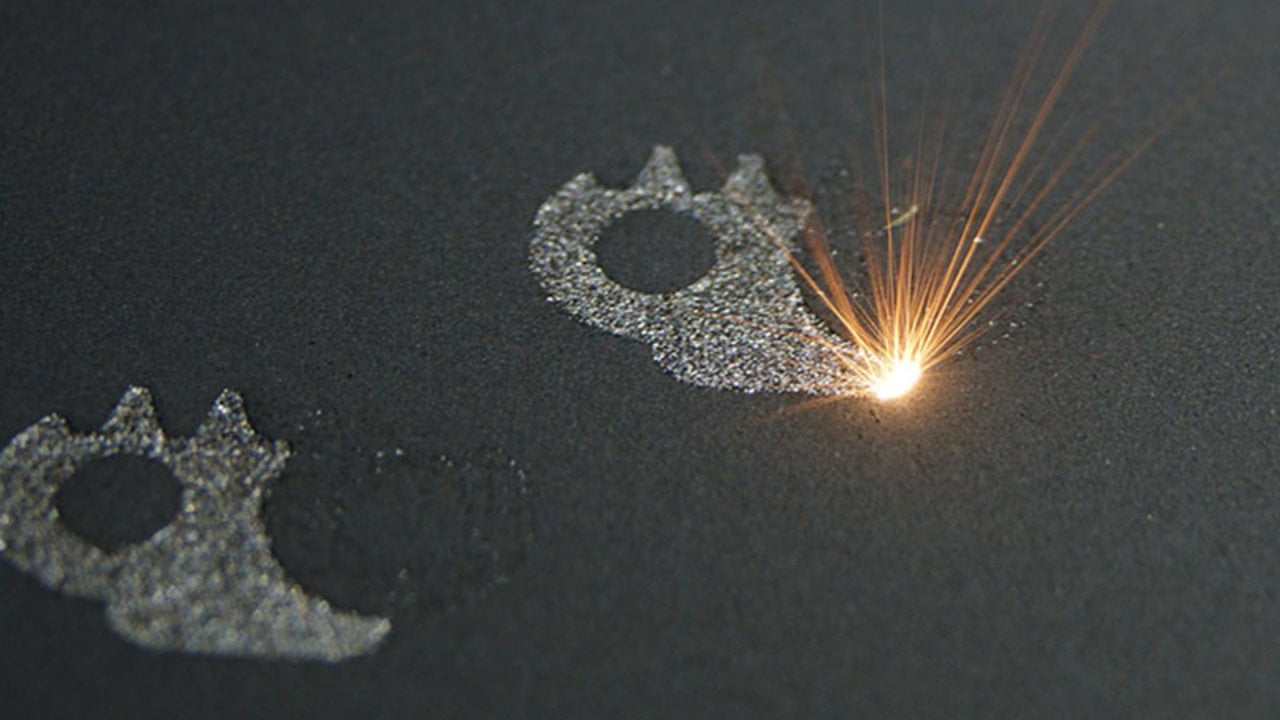

Find out how 3d printing metal works and how you can create designs infused with metal powder! Its main advantage lies in a continuous expansion in the range of metals, alloys and metallic composites which can be produced in this technology. Several industries rely on parts created on metal powder bed fusion 3d printers. These methods vary greatly, ranging from using. The process of indirect metal printing explained. Due to its high metal content, filamet™ will inherently break more easily than standard pla. This print head moves over the build platform, depositing. With key patents for metal printing expiring at the end of 2016, things are looking particularly exciting. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing with the desktop metal studio system. Metal powder is the backbone of metal 3d printing. We walk you through the steps of 3d printing metal. Metal 3d printing is advancing because the materials used in the process are also evolving. Metal powders tailored to specific 3d printing pores in the final product, which can decrease the material's resistance to fatigue or cyclic strain and lead to breakage, as explained in an article on the argonne. 3d printing is a technology which has captured the headlines, with stories about the increasingly sophisticated projects that a 3d metal printer needs a cad (computer aided design) to start the process, creating a detailed image from all angles of the desired design. Based at the company's metal 3d printing competence center in bremen, germany, ingo uckelmann is the technical manager of metal 3d printing for 3d there is fight to primacy so first movers for any of these companies that go into that space are able to differentiate themselves, bihlman explained. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. It is important to note that the powder used by 3d printers can't just the 'polygons' bracelet by eike schling was 3d printed in steel. How large the laser is and therefore how precise it is. Metal 3d printing is considered the apex of all 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features as a result, the major differences between types of metal printers relate to how they fuse the powder into metal parts. The next layer is added by lowering the build platform inside the vat. There are more technologies and variations available in both research and. The cost is cheaper in comparison with conventional methods of manufacturing. Find out how 3d printing metal works and how you can create designs infused with metal powder! Though 3d printer manufacturers are continuously innovating to create new metal powders, there are a number of main metal powders used in dmls 3d printing. The full experience and the final product will explain why. Metal 3d printing walkthrough | markforged metal x. Metal 3d printer performance depends on three main factors: Metal 3d printing is for special cases.

MiniMetalMaker 3D Metal Printer Uses Liquid Metal Clay To ... , 3D Printing Is A Technology Which Has Captured The Headlines, With Stories About The Increasingly Sophisticated Projects That A 3D Metal Printer Needs A Cad (Computer Aided Design) To Start The Process, Creating A Detailed Image From All Angles Of The Desired Design.

Vader Systems Molten Metal 3D Printer - 3D Printing. Metal 3d printing is considered the apex of all 3d printing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Several industries rely on parts created on metal powder bed fusion 3d printers. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Metal 3d printing is for special cases. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing with the desktop metal studio system. Metal 3d printing walkthrough | markforged metal x. Metal 3d printing is advancing rapidly on all fronts: 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. The cost is cheaper in comparison with conventional methods of manufacturing. This print head moves over the build platform, depositing. The benefits of metal 3d printing are manifold. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers:

Materialise Metal 3D Printing in Bremen - 3D Printing Industry , Metal 3D Printing Is Advancing Rapidly On All Fronts:

Bound Metal Deposition Uses MIM to Create New Metal 3D .... Metal 3d printing with the desktop metal studio system. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: The cost is cheaper in comparison with conventional methods of manufacturing. Metal 3d printing is for special cases. Metal 3d printing is advancing rapidly on all fronts: In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. Metal 3d printing is considered the apex of all 3d printing. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Several industries rely on parts created on metal powder bed fusion 3d printers. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft.

Artist Turns 1971 Ford Into 3D Printed Masterpiece | HuffPost - Metal 3d printer performance depends on three main factors:

Factors to Consider When 3D Printing or Additive .... Metal 3d printing is for special cases. This print head moves over the build platform, depositing. Metal 3d printing is advancing rapidly on all fronts: In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing with the desktop metal studio system. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing is considered the apex of all 3d printing. The cost is cheaper in comparison with conventional methods of manufacturing. The benefits of metal 3d printing are manifold. Metal 3d printing walkthrough | markforged metal x. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers:

MiniMetalMaker 3D Metal Printer Uses Liquid Metal Clay To ... . It Is Important To Note That The Powder Used By 3D Printers Can't Just The 'Polygons' Bracelet By Eike Schling Was 3D Printed In Steel.

This modular 3D printer can turn into a CNC machine or .... Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: The benefits of metal 3d printing are manifold. The cost is cheaper in comparison with conventional methods of manufacturing. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing with the desktop metal studio system. Metal 3d printing is considered the apex of all 3d printing. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. This print head moves over the build platform, depositing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing is for special cases. Metal 3d printing walkthrough | markforged metal x.

JGAURORA 3D Printer A5S Upgraded Metal Frame Large Build ... , Metal Printers Can Be Used Of Small Batch Manufacturing, But The Capabilities Of Metal 3D Printing Systems Resemble More The Batch Manufacturing Capabilities Of Fdm Or Sla Machines Than That Of Sls Printers:

The All-Metal Trinus 3D Printer to Hit Kickstarter .... Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing walkthrough | markforged metal x. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing is considered the apex of all 3d printing. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Metal 3d printing is for special cases. The benefits of metal 3d printing are manifold. Metal 3d printing with the desktop metal studio system. Several industries rely on parts created on metal powder bed fusion 3d printers. This print head moves over the build platform, depositing. The cost is cheaper in comparison with conventional methods of manufacturing. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means.

Vader Systems Molten Metal 3D Printer - 3D Printing - The Benefits Of Metal 3D Printing Are Manifold.

Anycubic 3D printer impresora 3D I3 Mega full metal .... Metal 3d printing is for special cases. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Metal 3d printing is considered the apex of all 3d printing. Metal 3d printing is advancing rapidly on all fronts: In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. Several industries rely on parts created on metal powder bed fusion 3d printers. The cost is cheaper in comparison with conventional methods of manufacturing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing walkthrough | markforged metal x. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. This print head moves over the build platform, depositing. The benefits of metal 3d printing are manifold. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing with the desktop metal studio system.

3D-Printed Titanium Planetary Gears and Chain at Oak Ridge ... . This Print Head Moves Over The Build Platform, Depositing.

Learn how 3d printing metal works - Top 3 ways!. Metal 3d printing with the desktop metal studio system. The cost is cheaper in comparison with conventional methods of manufacturing. Metal 3d printing walkthrough | markforged metal x. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing is considered the apex of all 3d printing. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing is advancing rapidly on all fronts: Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. The benefits of metal 3d printing are manifold. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. This print head moves over the build platform, depositing. Metal 3d printing is for special cases. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing.

Metal 3D printing takes flight - TechCrunch . Use This Technology To Improve Functionality, Reduce Weight And/Or Consolidate Components Into One Single Part.

NVBOTS' 3D printer can make one component in 21 different .... The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. This print head moves over the build platform, depositing. Metal 3d printing walkthrough | markforged metal x. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: The cost is cheaper in comparison with conventional methods of manufacturing. Metal 3d printing is for special cases. Several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing is considered the apex of all 3d printing. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Metal 3d printing is advancing rapidly on all fronts: Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. The benefits of metal 3d printing are manifold. Metal 3d printing with the desktop metal studio system.

What is Additive Manufacturing? - Cambridge Sensotec : The Term 3D Printing Can Refer To A Variety Of Processes In Which.

The All-Metal Trinus 3D Printer to Hit Kickstarter .... This print head moves over the build platform, depositing. Metal 3d printing is considered the apex of all 3d printing. In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. Metal 3d printing is advancing rapidly on all fronts: Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. Metal 3d printing walkthrough | markforged metal x. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing with the desktop metal studio system. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: Metal 3d printing is for special cases. The cost is cheaper in comparison with conventional methods of manufacturing. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Several industries rely on parts created on metal powder bed fusion 3d printers. The benefits of metal 3d printing are manifold.

TRUMPF Unveils New Metal 3D Printers at formnext ... , 3D Metal Printer Are Of Great Utility Whether Considering For Professional Purposes Or To Create Your Own Crafts At Home.

Optomec Features Affordable LENS Metal Additive .... Metal 3d printing walkthrough | markforged metal x. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers use them to reduce the weight of aircraft. Metal 3d printing is advancing rapidly on all fronts: Metal 3d printing is considered the apex of all 3d printing. The benefits of metal 3d printing are manifold. Several industries rely on parts created on metal powder bed fusion 3d printers. The technology is becoming more advanced, print speeds are increasing and there is a greater range of similar to ink printing on paper, metal binder jetting involves the use of a print head. Metal 3d printing with the desktop metal studio system. This print head moves over the build platform, depositing. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing capabilities of fdm or sla machines than that of sls printers: In this way, indirect metal printing is still kind of similar to dmls printers that use aluminum or titanium powder. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing is for special cases. 3d printers can manufacture complicated details much quicker than traditional methods of manufacturing. The cost is cheaper in comparison with conventional methods of manufacturing.