3D Printing Metal Accuracy. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Metal printing has a dimensional tolerance of ± 0.1 mm. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. How does metal 3d printing work? Find out how 3d printing metal works and how you can create designs infused with metal powder! Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. We walk you through the steps of 3d printing metal. Metal 3d printing is advancing rapidly on all fronts: The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Making metal 3d printing better. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space.

3D Printing Metal Accuracy . Find Out How 3D Printing Metal Works And How You Can Create Designs Infused With Metal Powder!

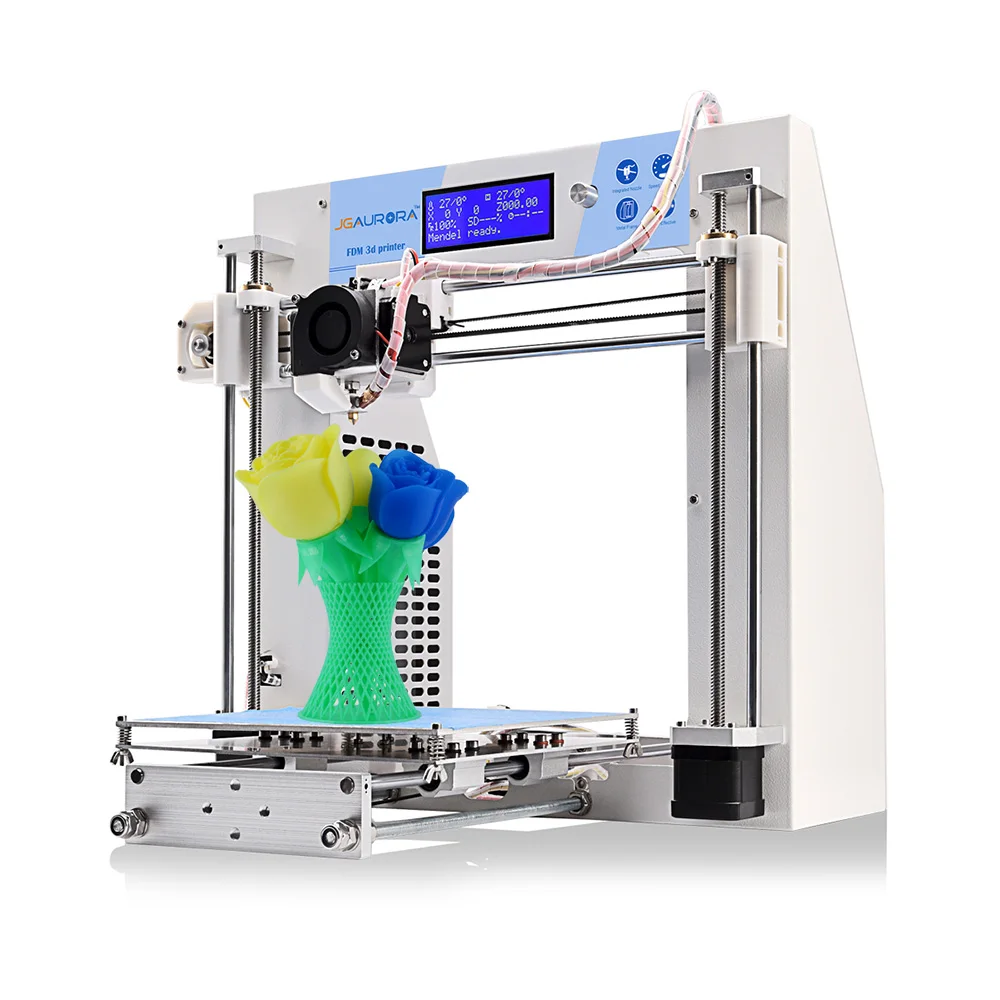

10 Best Metal 3D Printers - 3D Printer Review Site3D .... Making metal 3d printing better. How does metal 3d printing work? Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Metal 3d printing is advancing rapidly on all fronts: Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. We walk you through the steps of 3d printing metal. Find out how 3d printing metal works and how you can create designs infused with metal powder! As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Metal printing has a dimensional tolerance of ± 0.1 mm. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls.

3d printing is also known as additive manufacturing.

Even more impressively, these manufactures can also produce prints in precious metals, plated metal or ceramic. 3d printing is also known as additive manufacturing. Making metal 3d printing better. Additive manufacturing of new england. About 18% of these are machining. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. Learn how direct metal printing (dmp) can build your complex metal parts from 3d cad data. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Sculpteo provides you the best online 3d printing services for your metal parts. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Learn what accuracy, precision, and tolerance mean for your 3d printer, and how to think about them in the context of 3d printing and its applications. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. 3d printing has been gaining traction through many scientific and engineering disciplines as an easy way to print complex hierarchical structures, some of which are not possible by other means. Metal 3d printing is advancing rapidly on all fronts: Custom 3d laser metal printing. The 3d printing metals market comprises multiple different printer technologies. Metal 3d printing services located in middletown. The materials are printed together — supports out of metal, thin release layer of ceramic, and then the part out of metal. During the printing process, all material is bound with plastic. Our metal 3d printing service gives you an range of build envelopes of up to 400 x 400 x 360mm in aluminium and inconel. Sls printing technology has high accuracy and the surface of the prints is rather matte and grainy. Metal 3d printing is a burgeoning area at the moment. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Learn everything about 3d printing in stainless steel: Sintering removes the binder from both the metal and the ceramic, leaving you with the ceramic powder between the. Alibaba.com offers 21,133 3d printing metal products. Exone makes sand printers with a comparable accuracy to voxeljet systems while the latter have larger build volumes and higher throughput. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Despite advances in metal 3d printing, most of us will still have to rely on 3d printing services, as desktop or benchtop options remain within budget ranges more typical for both 3d printers are meant to cover every step in the metal printing process and allow users to print custom 3d objects.

RAPID + TCT Returns to "The Steel City" as Metal 3D ... . Sintering Removes The Binder From Both The Metal And The Ceramic, Leaving You With The Ceramic Powder Between The.

3D Systems Corporation (NYSE:DDD), Stratasys, Inc. (NASDAQ .... Metal printing has a dimensional tolerance of ± 0.1 mm. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Find out how 3d printing metal works and how you can create designs infused with metal powder! Making metal 3d printing better. How does metal 3d printing work? Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Metal 3d printing is advancing rapidly on all fronts: We walk you through the steps of 3d printing metal. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error.

10 Best Metal 3D Printers - 3D Printer Review Site3D ... : Learn Everything About 3D Printing In Stainless Steel:

Metal 3D printing takes flight - TechCrunch. Find out how 3d printing metal works and how you can create designs infused with metal powder! Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Making metal 3d printing better. Metal printing has a dimensional tolerance of ± 0.1 mm. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. How does metal 3d printing work? We walk you through the steps of 3d printing metal.

Industries: How 3D printing affects mechanics : Exone makes sand printers with a comparable accuracy to voxeljet systems while the latter have larger build volumes and higher throughput.

Industrial-Grade 3D Printers : metal 3d printer. How does metal 3d printing work? Making metal 3d printing better. Metal 3d printing is advancing rapidly on all fronts: We walk you through the steps of 3d printing metal. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Find out how 3d printing metal works and how you can create designs infused with metal powder! Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Metal printing has a dimensional tolerance of ± 0.1 mm. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before.

Buy Metal 3D Printer Large Size High Precision Quasi ... . A Wide Variety Of 3D Printing Metal Options Are Available To You, Such As Micro Machining Or Not, Cnc Machining Or Not, And Type.

Industrial Metal impresora 3D Printer with Imported .... Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Making metal 3d printing better. How does metal 3d printing work? Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Metal printing has a dimensional tolerance of ± 0.1 mm. Find out how 3d printing metal works and how you can create designs infused with metal powder! Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. We walk you through the steps of 3d printing metal. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal 3d printing is advancing rapidly on all fronts:

Aluminium Metal 3D Printer High Precision Large printing ... : While They Used To Be Only Industrial 3D Printers , Metal 3D Printing Is Now Becoming Cheap And Accessible Enough For Use In Far Lower Cost Rapid Prototyping — Thanks To Companies Like Desktop Metal.

Zhuhai CTC Electronic's Walnut Line is China's First .... Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. We walk you through the steps of 3d printing metal. Metal printing has a dimensional tolerance of ± 0.1 mm. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Making metal 3d printing better. Metal 3d printing is advancing rapidly on all fronts: As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. How does metal 3d printing work? Find out how 3d printing metal works and how you can create designs infused with metal powder!

Snapmaker: The All-Metal 3D Printer | 3D Printer Chat - Learn What Accuracy, Precision, And Tolerance Mean For Your 3D Printer, And How To Think About Them In The Context Of 3D Printing And Its Applications.

Infitary FDM Printing Technology Acrylic+Metal 3D Printer .... Making metal 3d printing better. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Find out how 3d printing metal works and how you can create designs infused with metal powder! As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. How does metal 3d printing work? We walk you through the steps of 3d printing metal. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Metal 3d printing is advancing rapidly on all fronts: The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal printing has a dimensional tolerance of ± 0.1 mm. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls.

Renishaw launch new 3D metal printer at IMTS, plan to ... - How Does Metal 3D Printing Work?

High Precision Metal 3d Printing Slm 3d Printer Metal 3d .... Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. How does metal 3d printing work? Making metal 3d printing better. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Metal printing has a dimensional tolerance of ± 0.1 mm. Metal 3d printing is advancing rapidly on all fronts: Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. We walk you through the steps of 3d printing metal. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Find out how 3d printing metal works and how you can create designs infused with metal powder!

Parts Manufacturer Adopts 3D Printing - 3D Printing Industry : Alibaba.com Offers 21,133 3D Printing Metal Products.

Metal 3D Printing: MatterFab Raises $5.75 Million In .... Metal printing has a dimensional tolerance of ± 0.1 mm. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Making metal 3d printing better. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. We walk you through the steps of 3d printing metal. Metal 3d printing is advancing rapidly on all fronts: How does metal 3d printing work? As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Find out how 3d printing metal works and how you can create designs infused with metal powder!

5 Trends in 3D Printing for 2018 | Materialise ... : Despite The Difficulties Of Maintaining The Oxygen Free Chamber, Lens Allows Users A Degree Of Accuracy And Control That Few Additive Manufacturing Methods Are Able To.

Materialise Enhances Concept Laser Metal 3D Printing with .... Metal printing has a dimensional tolerance of ± 0.1 mm. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. Find out how 3d printing metal works and how you can create designs infused with metal powder! Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Making metal 3d printing better. We walk you through the steps of 3d printing metal. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. Metal 3d printing is advancing rapidly on all fronts: Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. How does metal 3d printing work?

2019 Enterprise Metal 3D Printer of the Year: The Wildcard ... , Sculpteo Provides You The Best Online 3D Printing Services For Your Metal Parts.

3D Solutech Silver Metal 3D Printer PLA Filament 1.75MM .... Despite the difficulties of maintaining the oxygen free chamber, lens allows users a degree of accuracy and control that few additive manufacturing methods are able to. Metal 3d printing is advancing rapidly on all fronts: Metal printing (specifically dmls and slm) use a laser to selectively sinter or melt metal powder to produce metal parts. We walk you through the steps of 3d printing metal. Find out how 3d printing metal works and how you can create designs infused with metal powder! Cold spray metal printing cold spray metal printing was originally used by nasa to build metal objects in space. Although there are several different metal 3d printing services, the most common ones check the 3d hubs knowledge base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Since the cost of metal 3d printed parts is high, simulations are often used to validate the accuracy of a design, before starting the print job. As one might guess from reading this, avoiding issues in metal am still requires a lot of process knowledge and trial and error. The technology is becoming more advanced, print speeds are increasing and there is a greater range of industrial materials than ever before. Ebm also tends produce metal parts with a lower level of accuracy when compared to slm and dmls. Metal printing has a dimensional tolerance of ± 0.1 mm. Every geometry alters the variables of the machine, often forcing machine operators to print the same part several times in order to finally. How does metal 3d printing work? Making metal 3d printing better.