3D Printing Infill. What is infill in 3d printing? Best infill for strength vs material used. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The density of your infill makes a huge difference in the weight and durability of your print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill inside your 3d printed part plays a very important role in the overall strength of your model. 0% is generally equivalent to no infill. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Amongst the ten standard types. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong.

3D Printing Infill : Without Infill, Printing The Top Layers Would Be Very Difficult , As The Plastic Would Sag Over The Empty Parts Of The Print.

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. What is infill in 3d printing? Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. Best infill for strength vs material used. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. The density of your infill makes a huge difference in the weight and durability of your print. Amongst the ten standard types. 0% is generally equivalent to no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill inside your 3d printed part plays a very important role in the overall strength of your model.

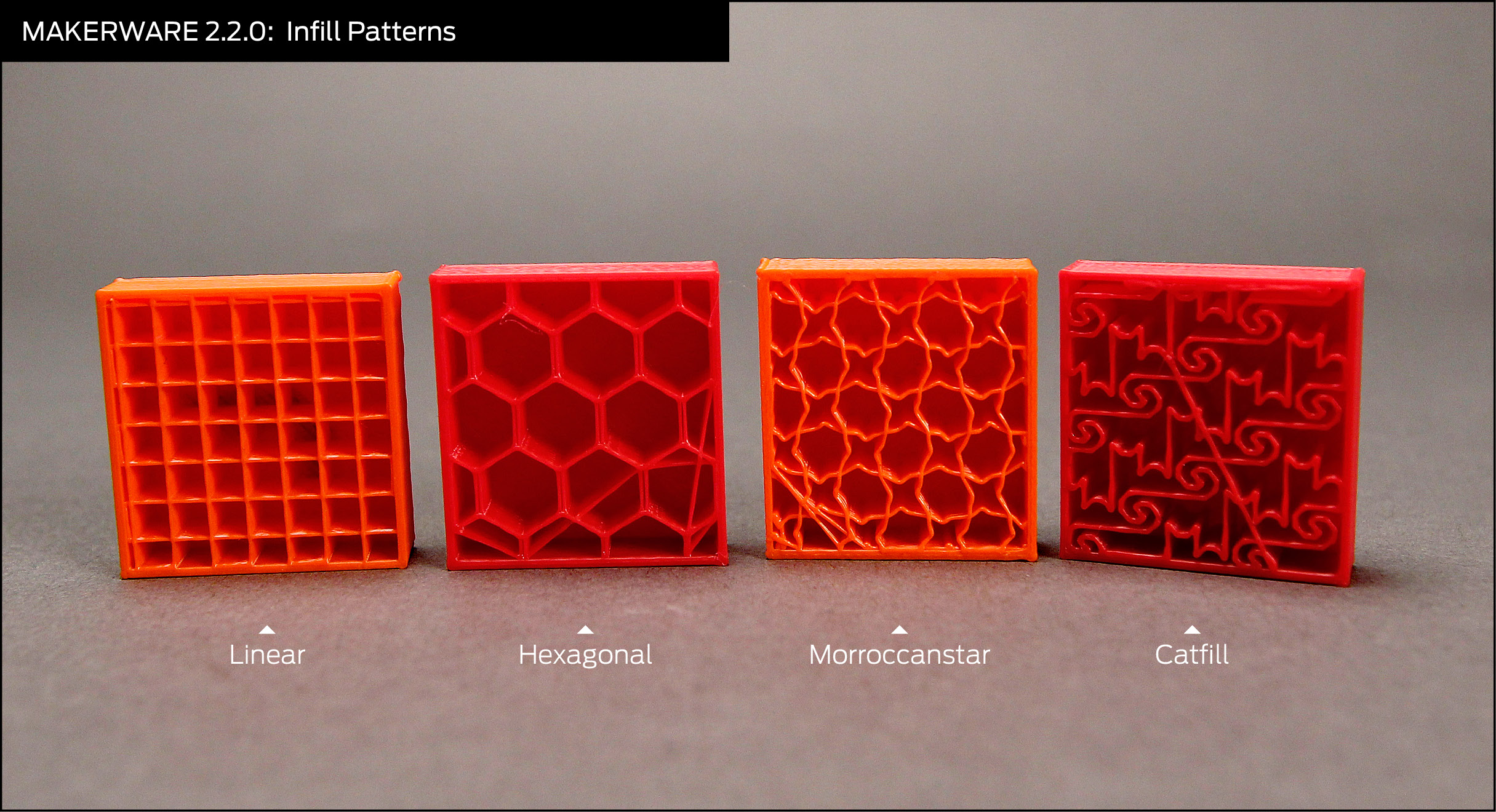

Amongst the ten standard types.

Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Basically the final 3d printed model will have different infill densities depending on the region of the model. The infill the amount of material that occupies the internal part of the piece. 0% is generally equivalent to no infill. The workflow was based in the following processes the 3d parts were 3d printed without the tops and bottoms for a better visualization of the different infill densities. The slicer, also called slicing software, is computer software used in the majority of 3d printing processes for the conversion of a 3d object model to specific instructions for the printer. Print with dual multiple extruders. The density of your infill makes a huge difference in the weight and durability of your print. The key parameters we look into are infill %, layer height and infill pattern. They are least likely to deform and provide the best support structure behind the walls of the strength and the speed combined makes triangular infill one of the best choices for infill in 3d printing. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. There is a little more to infill patterns than i first realized, so i will go into. As of right now i can choose from a total of 7 different infill. Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like: Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Best infill for strength vs material used. In the main body of this study, we provide a detailed description of the influence these parameters have on max stress, elongation at. Infill percentage in 3d printing. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. It can be difficult to explain important 3d printing concepts like infill percentage, shells, resolution, and the need for supports, smith explains. Often the drill holes will go through the top and bottom layers of the for cheap rapid prints rectangular infill it the best selection due to its quick print speed. The infill lines usually print at a 45° angle. If strength is critical to the function of a 3d printed part. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. Use brim for the best adhesion. Print beautiful colored objects, or use your secondary extruder to build support material. If the top of the model closes gradually, it can be printed hollow (0% infill), though we generally do not recommend it. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This unique feature improves built plate adhesion by generating a base flange around your. Consider a print with low infill that is going to be drilled and then screwed to another surface.

INFILL pattern and SHELLS - How to get the maximum ... , This Shape Is The Most Efficient Infill And Fastest To Print, The Goto Infill For Most Things.

Infill and Strength: Functional Design Doesn't Stop at the .... Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. 0% is generally equivalent to no infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. What is infill in 3d printing? A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The density of your infill makes a huge difference in the weight and durability of your print. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Amongst the ten standard types. Best infill for strength vs material used. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill inside your 3d printed part plays a very important role in the overall strength of your model.

Infill Percent Display by duncan916 - Thingiverse : Printing At Higher Infill Densities Will Of Course Make Your Object Stronger, But At The Cost Of More Materials, Longer Printing Times, And Reduced The Specific Infill Pattern You Use Will Have A Huge Effect On The Strength Of The Finished Part.

INFILL pattern and SHELLS - How to get the maximum .... What is infill in 3d printing? This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. Amongst the ten standard types. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The density of your infill makes a huge difference in the weight and durability of your print. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to.

3D Printing infill 100% vs 20% GoPro - YouTube . Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part.

The Best Cura Infill Pattern (for Your Needs) | All3DP. What is infill in 3d printing? Best infill for strength vs material used. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The density of your infill makes a huge difference in the weight and durability of your print. 0% is generally equivalent to no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Amongst the ten standard types. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

Delta WASP 3MT clay extruder / 3D PRINTING CERAMICS ... , 3D Printer Designs 3D Printer Projects 3D Projects Printer Hacks 3D Printing Diy 3D Printing Service Printing Process Impression 3D Drones.

How to Use 3D Print Infill Settings - Increase Strength .... A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Best infill for strength vs material used. The infill inside your 3d printed part plays a very important role in the overall strength of your model. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. The density of your infill makes a huge difference in the weight and durability of your print. 0% is generally equivalent to no infill. Amongst the ten standard types. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

How strong is a 3D printed object? Single layer shell, 3% ... : Print With Dual Multiple Extruders.

What is the influence of infill %, layer height and infill .... The infill inside your 3d printed part plays a very important role in the overall strength of your model. Best infill for strength vs material used. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Amongst the ten standard types. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. 0% is generally equivalent to no infill. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. This shape is the most efficient infill and fastest to print, the goto infill for most things. The density of your infill makes a huge difference in the weight and durability of your print. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent.

3D Printing & Internal Geometry | An Often Overlooked ... : This Shape Is The Most Efficient Infill And Fastest To Print, The Goto Infill For Most Things.

3D Printing Infill Guide Basics, Patterns & Stability. The density of your infill makes a huge difference in the weight and durability of your print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. What is infill in 3d printing? 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. 0% is generally equivalent to no infill. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Amongst the ten standard types. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print.

Infill Percent Display by duncan916 - Thingiverse , Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

3D Printing - Layer Height Under The Microscope | 3D .... Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Amongst the ten standard types. 0% is generally equivalent to no infill. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Best infill for strength vs material used. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. The density of your infill makes a huge difference in the weight and durability of your print. What is infill in 3d printing?

139 best images about 3D Printing on Pinterest | 3d ... . Often The Drill Holes Will Go Through The Top And Bottom Layers Of The For Cheap Rapid Prints Rectangular Infill It The Best Selection Due To Its Quick Print Speed.

How to Choose an Infill for your 3D prints | 3d printing .... The infill inside your 3d printed part plays a very important role in the overall strength of your model. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. What is infill in 3d printing? The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Amongst the ten standard types. The density of your infill makes a huge difference in the weight and durability of your print. Best infill for strength vs material used. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 0% is generally equivalent to no infill. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent.

Common Problems in 3D Printing & How to Resolve Them ... - Consider A Print With Low Infill That Is Going To Be Drilled And Then Screwed To Another Surface.

Infill and Strength: Functional Design Doesn't Stop at the .... Amongst the ten standard types. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. The density of your infill makes a huge difference in the weight and durability of your print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. 0% is generally equivalent to no infill. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Infill and Strength: Functional Design Doesn't Stop at the ... : This Shape Is The Most Efficient Infill And Fastest To Print, The Goto Infill For Most Things.

Reprap development and further adventures in DIY 3D .... Without it, prints wouldn't have much once you've decided on a style, the next step is to set the density of your 3d printing infill, measured in percent. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Amongst the ten standard types. Best infill for strength vs material used. The density of your infill makes a huge difference in the weight and durability of your print. 0% is generally equivalent to no infill. The infill inside your 3d printed part plays a very important role in the overall strength of your model. What is infill in 3d printing? The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print.