3D Printing Infill Shapes. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. There are several infill shapes typically available in most slicer programs. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill percentage in 3d printing. Infill can look cool, add strength, and save money, but it all depends on the print. It's also decent as a flexible pattern, as the triangles can. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. For example, cura's infill patterns include honeycomb and triangles among others. And from a printing perspective, it saves valuable time! The infill the amount of material that occupies the internal part of the piece. Each style has its own strengths and weaknesses, and each its own use. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3D Printing Infill Shapes , Infill Patterns Are Sometimes Overlooked In 3D Printing Because It's Just One Part Of Many Settings For Your Prints.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly. It's also decent as a flexible pattern, as the triangles can. And from a printing perspective, it saves valuable time! For example, cura's infill patterns include honeycomb and triangles among others. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The infill the amount of material that occupies the internal part of the piece. Each style has its own strengths and weaknesses, and each its own use. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. There are several infill shapes typically available in most slicer programs. Infill percentage in 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill can look cool, add strength, and save money, but it all depends on the print. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part.

Printer material estimates are accurate and easy to calculate with 3d printing, because a printer knows how much material it uses when it extrudes a toolpath.

Infill percentage in 3d printing. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Basically the final 3d printed model will have different infill densities depending on the region of the model. Though a consistent infill pattern and size is sufficient for some 3d prints, this parameter can limit the possibilities of other objects. There are several infill shapes typically available in most slicer programs. The four most common infill shapes are for cheap rapid prints rectangular infill it the best selection due to its quick print speed. Thingiverse is a universe of things. I'm working on printing parts for a maker select v2 rebuild i designed, but i've noticed an excessive amount of ringing on my prints, mostly due. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. For a standard print, infill is simply printed as an angled hatch or a honeycomb shape. It's also decent as a flexible pattern, as the triangles can. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. While adding 3d structure to the infill of 3d printed objects won't make the objects any stronger, it will drastically reduce delamination, and be much more resistant to stresses in all three dimensions. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Make custom products in plastic, metal, full color and more high quality 3d printing materials. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Unfortunately we designed this the hard way, by literally drawing a cube and subtracting out the honeycomb shapes to leave behind the. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced cool huh? Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. This shape is the most efficient infill and fastest to print, the goto infill for most things. The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. Infill percentage in 3d printing. Make many of the shape in 3d printer with different patterns. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Can anyone explain how the different shape causes the structure to be stronger? Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. For example, cura's infill patterns include honeycomb and triangles among others. You can see the varied infill percentages of these shapes, with higher density at more sensitive spots, and lower at points where pressure is spread more evenly. Printing an object with 20% infill might mean a grid of squares with 5mm or 2mm spacing. If strength is critical to the function of a 3d printed part honeycomb or triangular. The infill the amount of material that occupies the internal part of the piece.

The importance of the type of infill in 3D printing - Firstly, I Am Unclear On How Hexagonal Infill Is Stronger Than, Say, Diamond Pattern.

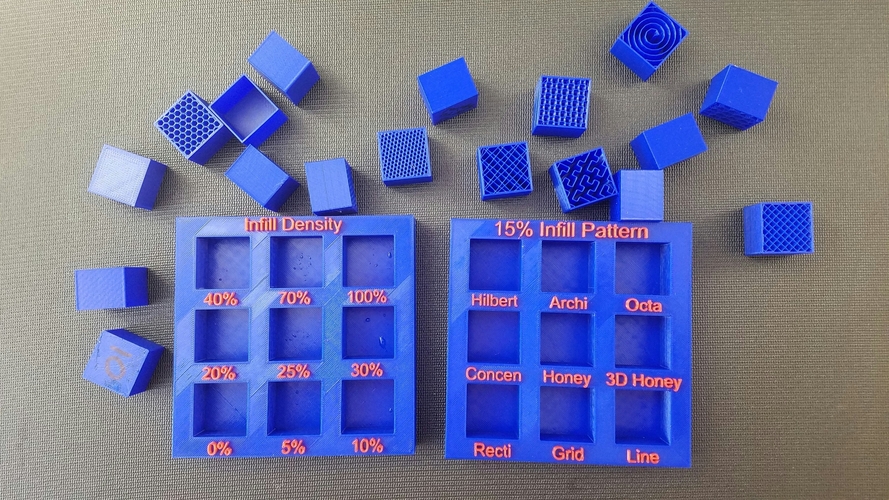

Posted @withrepost @neu3dlaboratories Testing different .... It's also decent as a flexible pattern, as the triangles can. For example, cura's infill patterns include honeycomb and triangles among others. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Infill percentage in 3d printing. There are several infill shapes typically available in most slicer programs. Each style has its own strengths and weaknesses, and each its own use. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill can look cool, add strength, and save money, but it all depends on the print. The infill the amount of material that occupies the internal part of the piece. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. And from a printing perspective, it saves valuable time!

3D Printing Infill: The Basics - Simply Explained | All3DP - Thingiverse Is A Universe Of Things.

These 3D Printable Tools Help You Understand Infill .... Each style has its own strengths and weaknesses, and each its own use. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. It's also decent as a flexible pattern, as the triangles can. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill percentage in 3d printing. Infill can look cool, add strength, and save money, but it all depends on the print. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. For example, cura's infill patterns include honeycomb and triangles among others. And from a printing perspective, it saves valuable time! The infill the amount of material that occupies the internal part of the piece.

3D Printed Infill percent display for learning 3D printer ... - Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

These 3D Printable Tools Help You Understand Infill .... Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. And from a printing perspective, it saves valuable time! Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. It's also decent as a flexible pattern, as the triangles can. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Each style has its own strengths and weaknesses, and each its own use. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. For example, cura's infill patterns include honeycomb and triangles among others. There are several infill shapes typically available in most slicer programs. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Infill can look cool, add strength, and save money, but it all depends on the print. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly - News, Information, Links, Help And Fun Related To 3D Printing, 3D Printers, Additive Manufacturing, Etc.

SEM images of 3D printed CHA scaffolds at different infill .... It's also decent as a flexible pattern, as the triangles can. Each style has its own strengths and weaknesses, and each its own use. Infill can look cool, add strength, and save money, but it all depends on the print. There are several infill shapes typically available in most slicer programs. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. The infill the amount of material that occupies the internal part of the piece. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Infill percentage in 3d printing. For example, cura's infill patterns include honeycomb and triangles among others. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. And from a printing perspective, it saves valuable time! Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

What's the Best Cura Infill Pattern for You Needs? | All3DP : It's Also Decent As A Flexible Pattern, As The Triangles Can.

Every material has a limit, but in 3D printing, those .... Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Infill percentage in 3d printing. For example, cura's infill patterns include honeycomb and triangles among others. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. It's also decent as a flexible pattern, as the triangles can. Each style has its own strengths and weaknesses, and each its own use. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. And from a printing perspective, it saves valuable time! Infill can look cool, add strength, and save money, but it all depends on the print. There are several infill shapes typically available in most slicer programs. The infill the amount of material that occupies the internal part of the piece.

How Does Infill Affect 3D Printing? - 3D Printing Industry , What Are The Cura Infill Shapes?

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. It's also decent as a flexible pattern, as the triangles can. Infill can look cool, add strength, and save money, but it all depends on the print. Infill percentage in 3d printing. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Each style has its own strengths and weaknesses, and each its own use. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. And from a printing perspective, it saves valuable time! The infill the amount of material that occupies the internal part of the piece. There are several infill shapes typically available in most slicer programs. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. For example, cura's infill patterns include honeycomb and triangles among others. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality.

How to Get Started with 3D Printing - 3D Printing Blog ... . Make Many Of The Shape In 3D Printer With Different Patterns.

How Does Infill Affect 3D Printing? - 3D Printing Industry. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. For example, cura's infill patterns include honeycomb and triangles among others. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill the amount of material that occupies the internal part of the piece. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. There are several infill shapes typically available in most slicer programs. And from a printing perspective, it saves valuable time! Infill percentage in 3d printing. Each style has its own strengths and weaknesses, and each its own use. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill can look cool, add strength, and save money, but it all depends on the print. It's also decent as a flexible pattern, as the triangles can. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part.

3D Printed Lamp Shade with Visible Gyroid Infill by ... : Make Custom Products In Plastic, Metal, Full Color And More High Quality 3D Printing Materials.

3D Printed Patches for Esophageal Tissue Engineering - 3D .... Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill can look cool, add strength, and save money, but it all depends on the print. The infill the amount of material that occupies the internal part of the piece. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill percentage in 3d printing. Each style has its own strengths and weaknesses, and each its own use. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. And from a printing perspective, it saves valuable time! There are several infill shapes typically available in most slicer programs. For example, cura's infill patterns include honeycomb and triangles among others. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. It's also decent as a flexible pattern, as the triangles can. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

These 3D Printable Tools Help You Understand Infill ... : Which One Is Right For You Depends On What Type Of Object You're Planning On Creating And The 3D Printing Infill Strength You Require.

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. There are several infill shapes typically available in most slicer programs. The infill the amount of material that occupies the internal part of the piece. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. And from a printing perspective, it saves valuable time! Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. Infill can look cool, add strength, and save money, but it all depends on the print. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. For example, cura's infill patterns include honeycomb and triangles among others. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Each style has its own strengths and weaknesses, and each its own use. It's also decent as a flexible pattern, as the triangles can. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Infill percentage in 3d printing.

3D Print Infill Jewelry in 2020 | 3d printing, 3d printed ... . Unfortunately We Designed This The Hard Way, By Literally Drawing A Cube And Subtracting Out The Honeycomb Shapes To Leave Behind The.

3D Printable Infill percent display for teaching tool of .... Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. For example, cura's infill patterns include honeycomb and triangles among others. The triangle shape is just known to be extremely strong geometrically, and it definitely shows in the print quality. The cross 3d infill pattern creates those curves with spaces in between, replicating cross shapes inside infill density affects a number of important parameters for your 3d printed part. Each style has its own strengths and weaknesses, and each its own use. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. There are several infill shapes typically available in most slicer programs. It's also decent as a flexible pattern, as the triangles can. Without it, prints wouldn't have much infill comes in many shapes, sizes, and patterns. And from a printing perspective, it saves valuable time! Infill can look cool, add strength, and save money, but it all depends on the print. Which one is right for you depends on what type of object you're planning on creating and the 3d printing infill strength you require. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.