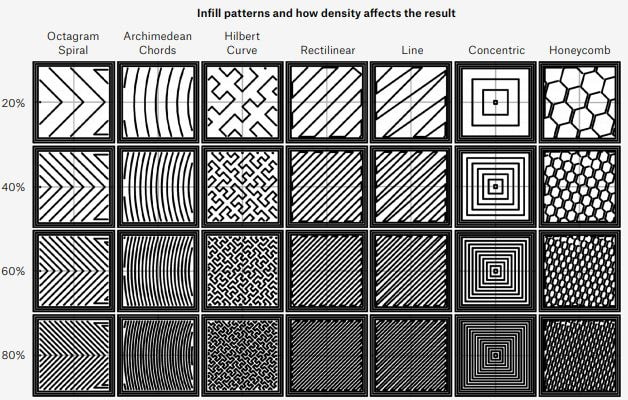

3D Printing Infill Settings. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to infill patterns, i think slic3r has. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. What is infill in 3d printing? The infill inside your 3d printed part plays a very important role in the overall strength of your model. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions.

3D Printing Infill Settings . The Printer Will Still Ooze A Little Bit Of Filament Due To The Pressure In The Nozzle, But By Stopping The Extrusion Early, You'll Reduce Over Extrusion On The Shell.

3D Print Infill Patterns Explained - The 3D Bros. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. The infill inside your 3d printed part plays a very important role in the overall strength of your model. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. When it comes to infill patterns, i think slic3r has. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

I know you said to disable the print outlines before the infill but the screenshot you link to says the.

When having a small numbers of shells, and infill. Our standard quality print settings are at a.25mm layer height. Many of the problems that makers run into when 3d printing is during filament extrusion. Having trouble with your 3d printer settings? Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Before i begin i wanted to say a special thanks to shaji on facebook and @shaji84 on instagram for providing the photo. In this step, i will show some photos of the printing process, and the final 3d prints. Most people like a honeycomb pattern. Getting a good baseline is crucial. The truth is that as long as you go with a regular infill like honeycomb, grid, rectilinear, etc., then you're probably good. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. The infill settings can affect the outcome of your print in various ways There are several infill patterns but when looking through the list, i wondered to myself, which infill pattern is the best in 3d printing? Shell and infill properties impact the performance and cost of fdm 3d printing. I'm trying to have this bracket printed, but i don't know what settings i should use. Learn how to optimize these features for your 3d printed part. We then hone in the retraction settings for pla. The project details say 50% for infill, but is there a reason why i wouldn't get 100% for making it sturdier? Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Upon clicking the … next to enable retraction we have our infill overlap refers to the percentage the infill will overlap onto the shells. If you want your print to be strong, choose infills like grid. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Consider a print with low infill that is going to be drilled and then screwed to another surface. Often the drill holes will go through the top and bottom layers of the. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. I continued to have issues with certain. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls.

Simplify3d-docs . Consider A Print With Low Infill That Is Going To Be Drilled And Then Screwed To Another Surface.

3D Printer Infill Settings - The Basics - YouTube. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill inside your 3d printed part plays a very important role in the overall strength of your model. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. When it comes to infill patterns, i think slic3r has. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. Infill provides the 3d print with internal support as the printer builds each layer. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly . Furthermore, Infill Allows Printers To Print Flat Horizontal Edges Over Empty Space Reliably And Efficiently.

MakerBot Introduces MinFill: A Fast, Thrifty New 3D .... This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to infill patterns, i think slic3r has. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. What is infill in 3d printing? The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print.

PLA 3D Printing Settings & Tips | PLA Material Profile ... : Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like:

How infill and shell parameters affect the strength of an .... What is infill in 3d printing? Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. When it comes to infill patterns, i think slic3r has. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. The infill inside your 3d printed part plays a very important role in the overall strength of your model. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls.

Ashley's Gold Box of Wonders | Simplify3D Software : Some Of The More Common Problems Are The Strength Of Your Print Will Vary Depending On What Kind Of Internal Infill You Choose.

How to Use Infill Percentage and Pattern - Enhance .... Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. When it comes to infill patterns, i think slic3r has. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions.

3D Slicing Settings for Big 3D Print - FLASHFORGE - Rectangular Infill Is The Only Infill Type That Can Achieve A 100% Dense Part Because It Consists Of A Grid Of Parallel And Perpendicular Extrusions.

Infill and Strength: Functional Design Doesn't Stop at the .... The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. What is infill in 3d printing? When it comes to infill patterns, i think slic3r has. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions.

Common Problems in 3D Printing & How to Resolve Them ... , Often The Drill Holes Will Go Through The Top And Bottom Layers Of The.

3d printing news - B3D-ONLINE. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. When it comes to infill patterns, i think slic3r has. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Infill provides the 3d print with internal support as the printer builds each layer. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Learn how infill %, infill patterns and layer height impact the strength of a 3d print.

Change Infill Density in a Specific Section on a 3D Model ... , The Infill Inside Your 3D Printed Part Plays A Very Important Role In The Overall Strength Of Your Model.

10 Advanced 3D Slicer Settings That Will Save Your Prints!. Infill provides the 3d print with internal support as the printer builds each layer. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. When it comes to infill patterns, i think slic3r has. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. What is infill in 3d printing? Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. The infill inside your 3d printed part plays a very important role in the overall strength of your model. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs.

PLA 3D Printing Settings & Tips | PLA Material Profile ... - Getting A Good Baseline Is Crucial.

The various infill patterns available in Ultimaker Cura .... Learn how infill %, infill patterns and layer height impact the strength of a 3d print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Infill provides the 3d print with internal support as the printer builds each layer. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. When it comes to infill patterns, i think slic3r has. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. What is infill in 3d printing? Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions.

Infill Percentage 3D Printing Terminology Demo by ... : Upon Clicking The … Next To Enable Retraction We Have Our Infill Overlap Refers To The Percentage The Infill Will Overlap Onto The Shells.

3d Printer Infill - Circuit Diagram Images. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. When it comes to infill patterns, i think slic3r has. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Infill provides the 3d print with internal support as the printer builds each layer.

Download free 3D printer files 3D print infill percentage ... . Just Curious Whether You're Recommending Infill Or Walls/Outlines Should Be Printed First.

Infill settings - Ultimaker Support. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Without infill, printing the top layers would be very difficult , as the plastic infill is a hugely important part of any print you'll do, but you need to know the right settings to use. Infill also affects the speed of printing, structural strength, filament consumption and even the look of the printed object. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Regardless of infill type or layer height, parts utilizing fff printing techniques can only achieve the strength of their base plastic at maximum. Infill provides the 3d print with internal support as the printer builds each layer. The printer will still ooze a little bit of filament due to the pressure in the nozzle, but by stopping the extrusion early, you'll reduce over extrusion on the shell. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. The infill is responsible for connecting the outer shells of your 3d print, and must also support the upper one of the first settings you should investigate is the infill pattern that is used for your print. What is infill in 3d printing? When it comes to infill patterns, i think slic3r has. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions.