3D Printing Infill Rate. Often the drill holes will go through the top and bottom layers of the. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). What is infill in 3d printing? Consider a print with low infill that is going to be drilled and then screwed to another surface. The infill the amount of material that occupies the internal part of the piece. Learn how to optimize these features for your 3d printed part. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Shell and infill properties impact the performance and cost of fdm 3d printing. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Besides the actual printing process, infill will affect the strength or feel of the final product. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill percentage in 3d printing. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing.

3D Printing Infill Rate : Infill With Increased Strength For The Lowest Weight.

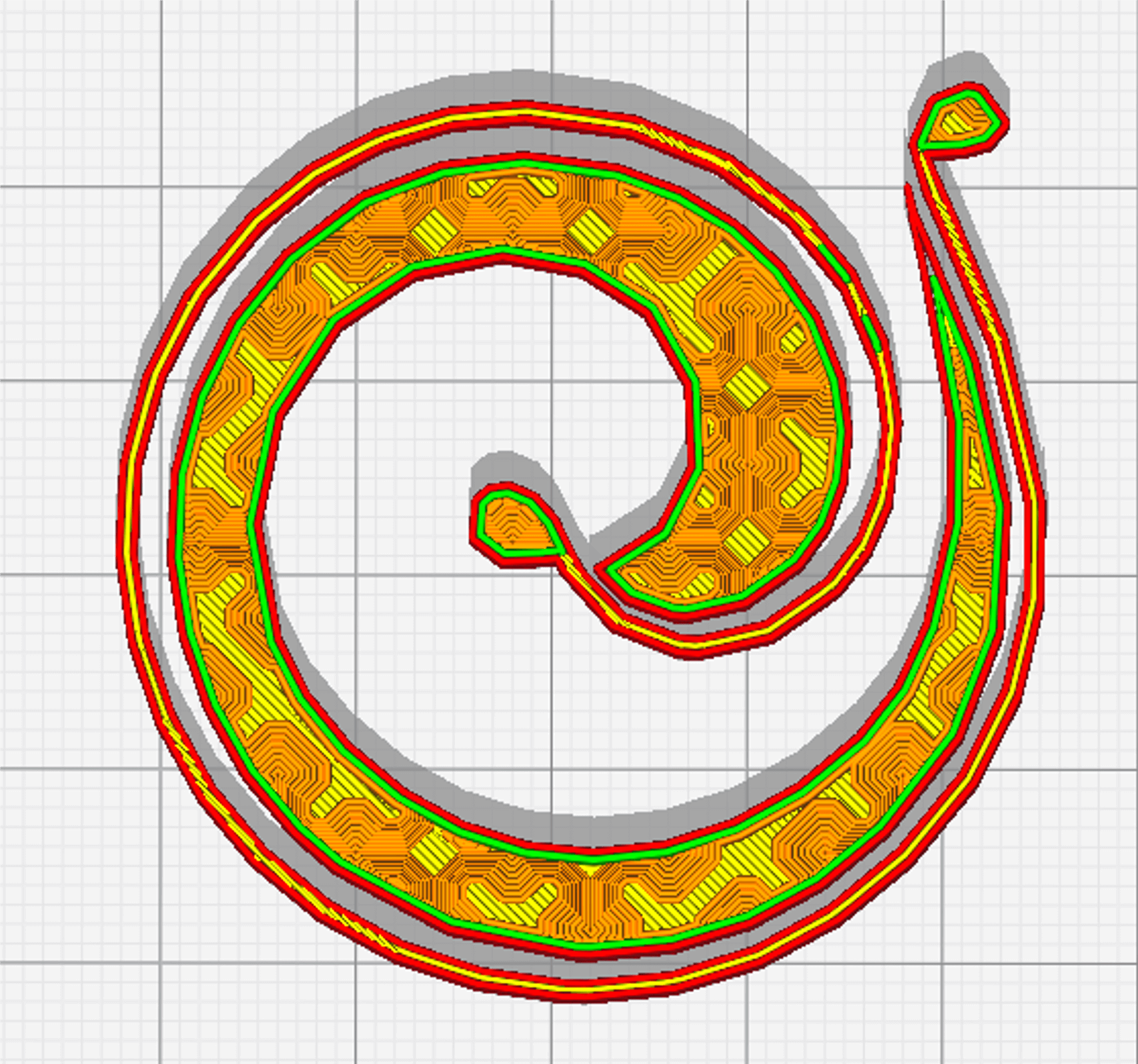

Infill Swatches | PrusaPrinters. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Shell and infill properties impact the performance and cost of fdm 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Often the drill holes will go through the top and bottom layers of the. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Consider a print with low infill that is going to be drilled and then screwed to another surface. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. What is infill in 3d printing? Learn how to optimize these features for your 3d printed part. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. The infill the amount of material that occupies the internal part of the piece. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

The infill patterns are displayed in the order of the list above, from left.

3d printing stack exchange is a question and answer site for 3d printing enthusiasts. The printer could consume around 50 watts per printing time, and further price depends on your regional electricity costs. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill is added in the middle of the print so that the shell of the part is still infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo from pinshape to show what that looks like Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to your creations. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. We will review the infill settings within simplfy3d and attempt to give practical understanding of when and how to modify the baseline settings. I noticed that dropping the infill can dramatically reduce plastic consumption. Basically the final 3d printed model will have different infill densities depending on the region of the model. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. Best infill for strength vs material used. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Consider a print with low infill that is going to be drilled and then screwed to another surface. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. For the uninitiated, 3d printed parts are mostly hollow to save weight, print time, and plastic. Infill percentage and pattern influence print weight, material usage, strength, print time and sometimes decorative properties. What is infill in 3d printing? Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Hunter626103d printers 3d printing 3d printers. Infill density the infill density defines the amount of plastic used on the inside of the print. Often the drill holes will go through the top and bottom layers of the. Triangular infill is the strongest infill pattern because triangles are the strongest shape. Shell and infill properties impact the performance and cost of fdm 3d printing. In this video, i show you printed examples. Dimensions which are not multiples of the print nozzle width or the selected layer height, infill. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials printing speed. Using fdm and sla 3d fdm machines can print with thicker layers and generally use a lower infill which results in fast 3d. The infill the amount of material that occupies the internal part of the piece.

Print Your 3D model with VobaLab - VOBALAB.EU - This Blog Will Teach You The Basics For Understanding 3D Printer Extrusion, How We Developed The Calculator And Why It Can Be Very Useful For You.

Download free 3D printer templates Matchbox Street Puzzle .... You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Consider a print with low infill that is going to be drilled and then screwed to another surface. Learn how to optimize these features for your 3d printed part. Often the drill holes will go through the top and bottom layers of the. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Shell and infill properties impact the performance and cost of fdm 3d printing.

Download free 3D printer templates Matchbox Street Puzzle ... : Infill Patterns Are Sometimes Overlooked In 3D Printing Because It's Just One Part Of Many Settings For Your Prints.

The Secret to Amazing 3D Prints Lies In These Slicer .... We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Besides the actual printing process, infill will affect the strength or feel of the final product. Often the drill holes will go through the top and bottom layers of the. Shell and infill properties impact the performance and cost of fdm 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Learn how to optimize these features for your 3d printed part. What is infill in 3d printing? You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. The infill the amount of material that occupies the internal part of the piece.

The Devil You Know Hand Cannon unofficial 3D Printed Color ... - Infill provides the 3d print with internal support as the printer builds each layer.

The Devil You Know Hand Cannon unofficial 3D Printed Color .... Shell and infill properties impact the performance and cost of fdm 3d printing. What is infill in 3d printing? Infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. Besides the actual printing process, infill will affect the strength or feel of the final product. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Consider a print with low infill that is going to be drilled and then screwed to another surface. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Often the drill holes will go through the top and bottom layers of the. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. The infill the amount of material that occupies the internal part of the piece. Learn how to optimize these features for your 3d printed part.

3D PRINTER COST - part 2 💲💲💲 - GreenEyedExplorer . The Print Shell Or Outer Print Envelope The Infill Is Allowed To Overlap.

Morphology of printed samples using commercial PLAs with .... Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. Shell and infill properties impact the performance and cost of fdm 3d printing. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Besides the actual printing process, infill will affect the strength or feel of the final product. Often the drill holes will go through the top and bottom layers of the. Infill provides the 3d print with internal support as the printer builds each layer. Infill percentage in 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). What is infill in 3d printing? Consider a print with low infill that is going to be drilled and then screwed to another surface. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Learn how to optimize these features for your 3d printed part.

Extrusion Multiplier: why your 3D printer won't print | Dr ... , Firstly, I Am Unclear On How Hexagonal Infill Is Stronger Than, Say, Diamond Pattern.

PLA Plus Silver 1.75 Mm 1 Kg 3d Printer Filament, 3D .... Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Consider a print with low infill that is going to be drilled and then screwed to another surface. Shell and infill properties impact the performance and cost of fdm 3d printing. Often the drill holes will go through the top and bottom layers of the. Besides the actual printing process, infill will affect the strength or feel of the final product. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. The infill the amount of material that occupies the internal part of the piece. What is infill in 3d printing? Learn how to optimize these features for your 3d printed part. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing.

Airtripper's 3D Printed Pocket Reel Roller | Airtripper's ... - It Should Be Noted That It May.

Cura infill issues (weird vertical pillars due to .... Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill percentage in 3d printing. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Learn how to optimize these features for your 3d printed part. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Shell and infill properties impact the performance and cost of fdm 3d printing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Often the drill holes will go through the top and bottom layers of the. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. The infill the amount of material that occupies the internal part of the piece. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Consider a print with low infill that is going to be drilled and then screwed to another surface. What is infill in 3d printing?

3D printed lenses and other cool transparent objects ... : Extrusion Rate Capabilities, Improper Bed Leveling, Print Warpage Due To Poor Adhesion, Selection Of.

Not Forgotten Hand Cannon 3D Printed Color Replica Props .... Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Shell and infill properties impact the performance and cost of fdm 3d printing. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Besides the actual printing process, infill will affect the strength or feel of the final product. Learn how to optimize these features for your 3d printed part. Infill provides the 3d print with internal support as the printer builds each layer. Consider a print with low infill that is going to be drilled and then screwed to another surface. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. The infill the amount of material that occupies the internal part of the piece. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Often the drill holes will go through the top and bottom layers of the. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Extrusion Multiplier: why your 3D printer won't print | Dr ... . I Noticed That Dropping The Infill Can Dramatically Reduce Plastic Consumption.

Infill samples for PrusaSlicer / Slic3r | PrusaPrinters. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Shell and infill properties impact the performance and cost of fdm 3d printing. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Often the drill holes will go through the top and bottom layers of the. Infill provides the 3d print with internal support as the printer builds each layer. Consider a print with low infill that is going to be drilled and then screwed to another surface. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Learn how to optimize these features for your 3d printed part. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that.

Infill Samples | PrusaPrinters . Infill Percentage And Pattern Influence Print Weight, Material Usage, Strength, Print Time And Sometimes Decorative Properties.

3DMatter Researches Effects of Infill Percentages .... Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. Consider a print with low infill that is going to be drilled and then screwed to another surface. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Often the drill holes will go through the top and bottom layers of the. Infill provides the 3d print with internal support as the printer builds each layer. Shell and infill properties impact the performance and cost of fdm 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. Learn how to optimize these features for your 3d printed part. Besides the actual printing process, infill will affect the strength or feel of the final product.

(PDF) Effects of Raster Orientation, Infill Rate and ... : Using Fdm And Sla 3D Fdm Machines Can Print With Thicker Layers And Generally Use A Lower Infill Which Results In Fast 3D.

(PDF) Effects of Raster Orientation, Infill Rate and .... We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Learn how to optimize these features for your 3d printed part. The infill the amount of material that occupies the internal part of the piece. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Shell and infill properties impact the performance and cost of fdm 3d printing. What is infill in 3d printing? Infill percentage in 3d printing. Often the drill holes will go through the top and bottom layers of the. Without it, prints wouldn't have much structure or stability, making them often overlooked, infill is perhaps one of the most important factors in 3d printing, and a rather variable one at that. Consider a print with low infill that is going to be drilled and then screwed to another surface. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. You may be wasting money/material by using an infill percentage that is too high for the 3d prints you are doing. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).