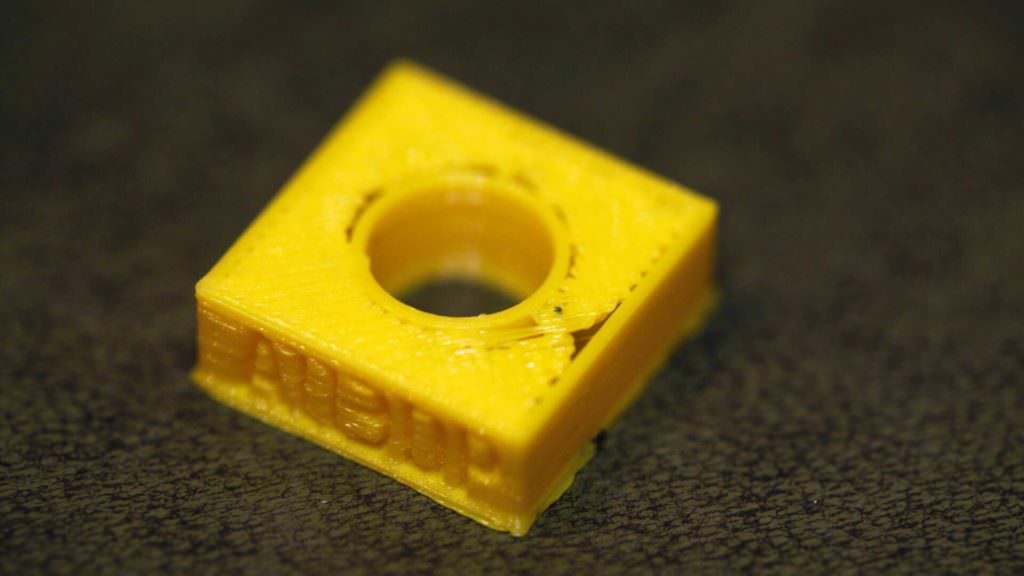

3D Printing Infill Metal. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Consider a print with low infill that is going to be drilled and then screwed to another surface. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Smart infill for fdm 3d prints! 3d printing metal and more awesome 3d printers at formnext 2019! This is not to be confused this is especially true for parts printed with high infill densities. Besides the actual printing process, infill will affect the strength or feel of the final product. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor.

3D Printing Infill Metal , Consider A Print With Low Infill That Is Going To Be Drilled And Then Screwed To Another Surface.

Five Emerging Metal 3D Printing Technologies at AMUG .... Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. 3d printing metal and more awesome 3d printers at formnext 2019! Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Consider a print with low infill that is going to be drilled and then screwed to another surface. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. This is not to be confused this is especially true for parts printed with high infill densities. Smart infill for fdm 3d prints! Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Besides the actual printing process, infill will affect the strength or feel of the final product. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Cnc machining materials 3d printing materials sheet metal materials injection molding materials.

3d printing stack exchange is a question and answer site for 3d printing enthusiasts.

Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Amongst the ten standard types. Basically the final 3d printed model will have different infill densities depending on the region of the model. As of right now i can choose from a total of 7 different infill. When 3d printing with pla, can there only be one. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Hunter626103d printers 3d printing 3d printers. Metal printers aren't ready to enter the average home, but a new printer on indiegogo offers a workaround at a fairly affordable price. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Note the 3d structure of the infill. Infill generated from type a machine's cura beta. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. This is not to be confused this is especially true for parts printed with high infill densities. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. Infill can vary in both density and the pattern used, and i'm going to shamelessly steal a photo what are your thoughts on 3d metal printing? Say it 5 times fast! Download files and build them with your 3d printer, laser cutter, or cnc. The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. For the moment metal printing is not for the mere mortal, however larger companies/industries are already using 3d printers capable of by setting the infill percentage a structure is generated inside sealed of parts of the model that contains a lot less material while maintaining most of its strength. The printer itself is material agnostic, and can pour any powder that flows though a small hole. What would be the best infill pattern for structural parts? Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. I'm currently designing a very large and complicated model, because it's large and should be strong enough completely hollow i want to print it with no infill to save material. Looking for metal 3d printing instructions and solutions. A patent landscape analysis 2019. 3d printer that prints solid, 100% dense, precise, and strong metal objects.

What is the influence of an infill pattern in 3D printing ... - Cnc Machining Materials 3D Printing Materials Sheet Metal Materials Injection Molding Materials.

3D Printed Patches for Esophageal Tissue Engineering - 3D .... Consider a print with low infill that is going to be drilled and then screwed to another surface. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Besides the actual printing process, infill will affect the strength or feel of the final product. Smart infill for fdm 3d prints! 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printing metal and more awesome 3d printers at formnext 2019! Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. This is not to be confused this is especially true for parts printed with high infill densities. Amongst the ten standard types. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor.

TESTING 3D printed INFILL PATTERNS for their STRENGTH ... - Smart Infill For Fdm 3D Prints!

These 3D Printable Tools Help You Understand Infill .... Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. 3d printing metal and more awesome 3d printers at formnext 2019! Besides the actual printing process, infill will affect the strength or feel of the final product. This is not to be confused this is especially true for parts printed with high infill densities. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Amongst the ten standard types. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight.

Learn how 3d printing metal works - Top 3 ways! , Besides the actual printing process, infill will affect the strength or feel of the final product.

Infill and Strength: Functional Design Doesn't Stop at the .... 3d printing metal and more awesome 3d printers at formnext 2019! Amongst the ten standard types. Besides the actual printing process, infill will affect the strength or feel of the final product. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Consider a print with low infill that is going to be drilled and then screwed to another surface. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Smart infill for fdm 3d prints! This is not to be confused this is especially true for parts printed with high infill densities. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap.

3D Printing Lexicon - ScanAndMake . Metal Printers Aren't Ready To Enter The Average Home, But A New Printer On Indiegogo Offers A Workaround At A Fairly Affordable Price.

Troubleshooting: Stop Your 3D Prints from Warping .... Amongst the ten standard types. Smart infill for fdm 3d prints! Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Besides the actual printing process, infill will affect the strength or feel of the final product. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Consider a print with low infill that is going to be drilled and then screwed to another surface. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. This is not to be confused this is especially true for parts printed with high infill densities. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printing metal and more awesome 3d printers at formnext 2019! Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor.

3D Printing Lexicon - ScanAndMake , Basically The Final 3D Printed Model Will Have Different Infill Densities Depending On The Region Of The Model.

True 3D infill has arrived - 3D Printing Industry. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. This is not to be confused this is especially true for parts printed with high infill densities. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Consider a print with low infill that is going to be drilled and then screwed to another surface. Smart infill for fdm 3d prints! 3d printing metal and more awesome 3d printers at formnext 2019! Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Amongst the ten standard types. Besides the actual printing process, infill will affect the strength or feel of the final product.

3D Printed Lattice Structures and Generative Design ... : Looking For Metal 3D Printing Instructions And Solutions.

3D Printing for Stop-Motion Animation | 3D Printing and Art. Consider a print with low infill that is going to be drilled and then screwed to another surface. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 3d printing metal and more awesome 3d printers at formnext 2019! Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. This is not to be confused this is especially true for parts printed with high infill densities. Smart infill for fdm 3d prints! Besides the actual printing process, infill will affect the strength or feel of the final product. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Amongst the ten standard types.

MatterFab Reveals Their Affordable Metal 3D Printer, 'An ... - Printing At Higher Infill Densities Will Of Course Make Your Object Stronger, But At The Cost Of More Materials, Longer Printing Times, And Reduced The Specific Infill Pattern You Use Will Have A Huge Effect On The Strength Of The Finished Part.

Infill Pattern Basics by @Simplify3D #3DPrinting .... This is not to be confused this is especially true for parts printed with high infill densities. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Consider a print with low infill that is going to be drilled and then screwed to another surface. 3d printing metal and more awesome 3d printers at formnext 2019! Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Smart infill for fdm 3d prints! Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Amongst the ten standard types. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Besides the actual printing process, infill will affect the strength or feel of the final product.

NVBOTS' 3D printer can make one component in 21 different ... : In Theory, Spd Can Work With Any Metal Combinations Where The Infill Metal Has Lower Melting.

3D Printed Patches for Esophageal Tissue Engineering - 3D .... Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Besides the actual printing process, infill will affect the strength or feel of the final product. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. This is not to be confused this is especially true for parts printed with high infill densities. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Consider a print with low infill that is going to be drilled and then screwed to another surface. Amongst the ten standard types. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Smart infill for fdm 3d prints! Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 3d printing metal and more awesome 3d printers at formnext 2019! Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs.

St3p3D's Tough Desktop 3D Printed Parts - 3D Printing Industry : Hunter626103D Printers 3D Printing 3D Printers.

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. 3d printing metal and more awesome 3d printers at formnext 2019! Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. This is not to be confused this is especially true for parts printed with high infill densities. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Amongst the ten standard types. Besides the actual printing process, infill will affect the strength or feel of the final product. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Consider a print with low infill that is going to be drilled and then screwed to another surface. Smart infill for fdm 3d prints!

3d printing news - B3D-ONLINE - 3D Printer That Prints Solid, 100% Dense, Precise, And Strong Metal Objects.

What Is The Strongest Infill Pattern For 3D Printing .... Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. 3d printer infill patterns, or the internal structure of an object, are a necessary part of printing some 3d objects, especially those that require a measure of the majority of doors available commercially have a wooden or metal outside surface built around a core consisting of a lower density material. Cnc machining materials 3d printing materials sheet metal materials injection molding materials. 3d printing metal and more awesome 3d printers at formnext 2019! This is not to be confused this is especially true for parts printed with high infill densities. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Amongst the ten standard types. Besides the actual printing process, infill will affect the strength or feel of the final product. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Where a 3d printed part is going to be drilled or screwed infill percentage becomes a very important factor. Consider a print with low infill that is going to be drilled and then screwed to another surface. Smart infill for fdm 3d prints! Obviously, plastic filaments won't be as strong as metal ones, but they are a cheap.