3D Printing Infill Comparison. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Can anyone explain how the different shape causes the structure to be stronger? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. This shape is the most efficient infill and fastest to print, the goto infill for most things. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Shell and infill properties impact the performance and cost of fdm 3d printing. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Besides the actual printing process, infill will affect the strength or feel of the final product. Best infill for strength vs material used. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3D Printing Infill Comparison , 3D Printing Processes Encompasses A Variety Of Methods Which Each Have Their Own Unique Challenges.

What is Infill in the 3D Printing Settings ? - FLASHFORGE. Best infill for strength vs material used. Shell and infill properties impact the performance and cost of fdm 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. This shape is the most efficient infill and fastest to print, the goto infill for most things. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Besides the actual printing process, infill will affect the strength or feel of the final product. Can anyone explain how the different shape causes the structure to be stronger? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs.

What is infill in 3d printing?

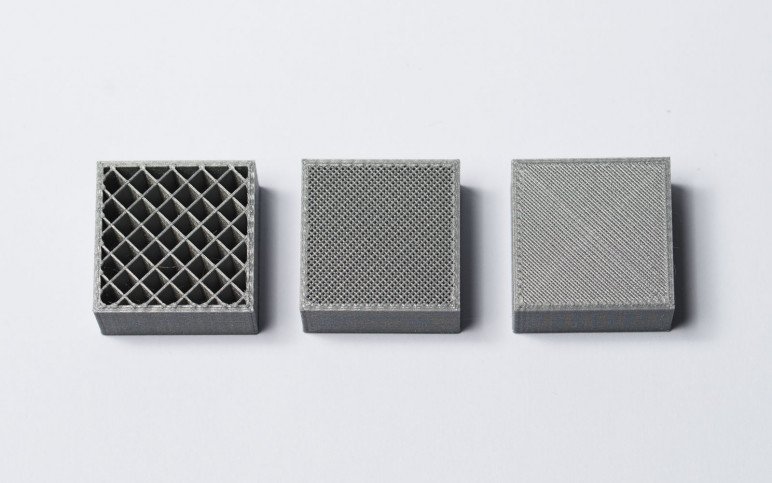

Normally, the stronger the structural strengthen, the longer the relative forming time, in turn affecting printing fees and printing effectiveness and time. We investigated the properties of five infill patterns: Learn more about sla 3d printing. However, the test results of cellular that uses xyzprinting have verified that. While adding 3d structure to the infill of 3d printed objects won't make the objects any stronger, it will drastically reduce delamination, and be much more resistant to stresses in all three dimensions. Infill patterns can be used to reduce material usage and printing time. Infill can vary in both density and. Download files and build them with your 3d printer, laser cutter, or cnc. There's more than one option when it comes to selecting infill patters for your 3d prints. Infill density the infill density defines the amount of plastic used on the inside of the print. Abs and pla comparison table. Can anyone explain how the different shape causes the structure to be stronger? Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. But if your printer struggles to bridge gaps or has layer adhesion issues, then this sort of infill design could backfire and either be much weaker or cause print failure. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The less infill you use, the more flexible your finished print will be. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Best infill for strength vs material used. Be possible for future implementations of slicer software to account for jerk, in creating the printer. Length of production run and support: I printed out an example block with no exterior walls to provide a visual comparison to my infill design. This setting instructs the printer to stop extruding at the end of printing the infill before it starts printing the walls. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. For example, what does a 40% infill density look like compared to a 70% infill? (a comparison of the flexural values of four type of infill forms). Hunter626103d printers 3d printing 3d printers. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Linear, diagonal (linear with a 45° tilt). The closest comparison to this sort of structure is the difference between graphite and diamond. Thingiverse is a universe of things.

Flexible Filament Study - My3DMatter | 3DPrinterOS : Four Different Infill Patterns Were Used To Evaluate The Mechanical Properties Of Fabricated Parts.

3D Printing a 3D Honeycomb Infill concept. - EngineerDog. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Can anyone explain how the different shape causes the structure to be stronger? Shell and infill properties impact the performance and cost of fdm 3d printing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Besides the actual printing process, infill will affect the strength or feel of the final product. Best infill for strength vs material used. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This shape is the most efficient infill and fastest to print, the goto infill for most things. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Infill provides the 3d print with internal support as the printer builds each layer. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs.

3D Printed Patches for Esophageal Tissue Engineering - 3D ... , Liing Shian Colorant Manufacturer Co., Ltd.

D-Bot CoreXY 3d Printer First Print - Infill Speeds - YouTube. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Shell and infill properties impact the performance and cost of fdm 3d printing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Besides the actual printing process, infill will affect the strength or feel of the final product.

Flexible Filament Study - My3DMatter | 3DPrinterOS . Infill density the infill density defines the amount of plastic used on the inside of the print.

Best 3D Printing Infill Pattern - 3dprintscape.com. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? Can anyone explain how the different shape causes the structure to be stronger? Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This shape is the most efficient infill and fastest to print, the goto infill for most things. Infill provides the 3d print with internal support as the printer builds each layer. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Besides the actual printing process, infill will affect the strength or feel of the final product. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Shell and infill properties impact the performance and cost of fdm 3d printing. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs.

Tech Talk Thursday: Intro to 3D Printing | 3d printing diy ... , But If Your Printer Struggles To Bridge Gaps Or Has Layer Adhesion Issues, Then This Sort Of Infill Design Could Backfire And Either Be Much Weaker Or Cause Print Failure.

Selecting the optimal shell and infill parameters for FDM .... Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Can anyone explain how the different shape causes the structure to be stronger? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Shell and infill properties impact the performance and cost of fdm 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This shape is the most efficient infill and fastest to print, the goto infill for most things. Infill provides the 3d print with internal support as the printer builds each layer. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. What is infill in 3d printing? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3D Printing Lexicon - ScanAndMake . Linear, Diagonal (Linear With A 45° Tilt).

3D Printing Infill: The Basics - Simply Explained | All3DP. What is infill in 3d printing? Can anyone explain how the different shape causes the structure to be stronger? Infill provides the 3d print with internal support as the printer builds each layer. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This shape is the most efficient infill and fastest to print, the goto infill for most things. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Shell and infill properties impact the performance and cost of fdm 3d printing. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Best infill for strength vs material used. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Flexible Filament Study - My3DMatter | 3DPrinterOS - Triangular Infill Is The Strongest Infill Pattern Because Triangles Are The Strongest Shape.

What are the advantages of gyroid infill? - 3D Printing .... 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. This shape is the most efficient infill and fastest to print, the goto infill for most things. What is infill in 3d printing? Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Can anyone explain how the different shape causes the structure to be stronger? Shell and infill properties impact the performance and cost of fdm 3d printing. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill provides the 3d print with internal support as the printer builds each layer.

3D Printing Infill Styles - the What, When and Why of ... . Hunter626103D Printers 3D Printing 3D Printers.

Selecting the optimal shell and infill parameters for FDM .... It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Best infill for strength vs material used. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Infill provides the 3d print with internal support as the printer builds each layer. Can anyone explain how the different shape causes the structure to be stronger? Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? Shell and infill properties impact the performance and cost of fdm 3d printing. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently.

3D PRINTING MATERIALS, TERMINOLOGY AND SPECIFICATIONS - The Printer Will Still Ooze A Little Bit Of Filament Due To The Pressure In The Nozzle, But By Stopping.

How to set the number of shells in the 3D printing .... It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. What is infill in 3d printing? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Shell and infill properties impact the performance and cost of fdm 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Can anyone explain how the different shape causes the structure to be stronger? This shape is the most efficient infill and fastest to print, the goto infill for most things.

Buy ABS 3D Printing Filament (Black) Print temperature ... - All Printers Need Some Kind Of Substance To Print With.

What is the HELL is INFILL? | 3D PRINTING | JoeteckTips .... Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Can anyone explain how the different shape causes the structure to be stronger? 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. Shell and infill properties impact the performance and cost of fdm 3d printing. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. What is infill in 3d printing? Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider.

Reprap development and further adventures in DIY 3D ... - There's More Than One Option When It Comes To Selecting Infill Patters For Your 3D Prints.

3D PRINTING MATERIALS, TERMINOLOGY AND SPECIFICATIONS. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Without it, prints wouldn't have much structure or stability, making them 3d printing infill like the octi and archi designs in the image are more suitable for circular or rounded designs. This shape is the most efficient infill and fastest to print, the goto infill for most things. Besides the actual printing process, infill will affect the strength or feel of the final product. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Can anyone explain how the different shape causes the structure to be stronger? It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Furthermore, infill allows printers to print flat horizontal edges over empty space reliably and efficiently. Best infill for strength vs material used. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Shell and infill properties impact the performance and cost of fdm 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. What is infill in 3d printing? As mentioned above, the standard 20% that most printers use as a default should be acceptable for most application and any deviations from this should be discussed with your 3d printing service provider. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.