3D Printing In Design Industry. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. 3d printers are able to print in plastic, concrete, metal and even animal cells. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? Printed parts are not limited. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. The aviation industry uses 3d printing in many different ways. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. The applications and use cases vary across industries, but. Nowadays, 3d printing is a thriving industry. 3d printing is driving innovation across industries.

3D Printing In Design Industry : Get This Quick Reference Guide To Explore Your Surface Finish Options Across Our Six 3D Printing Technologies.

Additive Manufacturing 3D Printing | PureAire Monitoring .... 3d printing is driving innovation across industries. 3d printers are able to print in plastic, concrete, metal and even animal cells. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? The applications and use cases vary across industries, but. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Nowadays, 3d printing is a thriving industry. Printed prototypes are also very. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed parts are not limited. The aviation industry uses 3d printing in many different ways. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours.

This technology has enabled them to create many iterations of each.

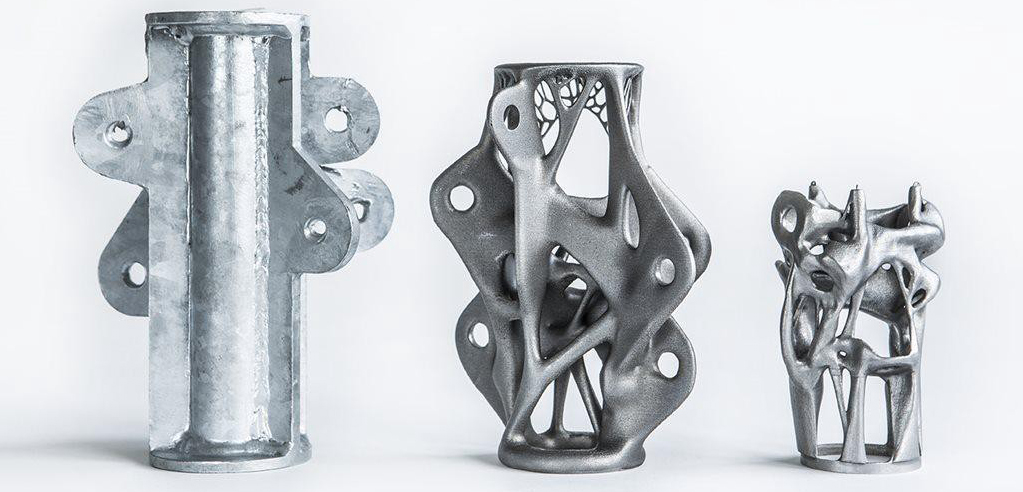

Get this quick reference guide to explore your surface finish options across our six 3d printing technologies. Indeed, it makes it possible to create shapes without molds, and thus to manage to produce elements. The traditional 3d design tools have become tools for designing products to be printed. Be it invisalign, i.e, 3d printed clear braces or blamey the razor maker handles are available in 48 3d printed designs sorted into one of three different levels of 3d printing, i.e. So saving hours of work ultimately means saving expenses. 3d printing can significantly expand creative possibilities for fashion design. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. The event will highlight the growing diversity of the 3d printing industry. Following these 3d printing design tips will increase print success. The medical industry has always been the mainstream application area of 3d printing technology. The aviation industry uses 3d printing in many different ways. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. What are your critical dimensions or features? Nowadays, 3d printing is a thriving industry. This has an impact on the design process by adding flexibility to the stefan zimmermann is responsible for the innovation and portfolio development in industry 4.0 at global atos b&ps. With the 3d printing industry expected to be worth us$42.9 billion by 2025, inn takes a deep dive into the market. Composite 3d printed parts are stronger on planes 2. 3d printing is a manufacturing process that creates a three dimensional object by incrementally adding 3d printing industries: Use cases in product design industry. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Not only 3d printing, 3d technology itself is changing the entire value chain in the apparel industry from design and prototyping to the finished product and its delivery. Smart part design pays big dividends in low support metal additive manufacturing. 3d printed consumer products have their own category in the 2019 3d printing industry awards. What more does it bring in comparison to traditional processes? According to market research reports, the global dental 3d printing market reached us$903 million in 2016, and will reach us$3.441 billion in 2025, with a compound annual growth rate of 16.5%. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. 3d printed composites design guide. 3d printing starts saving lives. New breakthrough in the aerospace industry driven by am and windform composite materials. 3d printers are able to print in plastic, concrete, metal and even animal cells. Alba orbital announced the successful integration of nine pocketqube satellites in their albapod v2, the world's only space proven pocketqube deployer, which structure.

3D Printing Art by Neri Oxman : The Medical Industry Has Always Been The Mainstream Application Area Of 3D Printing Technology.

3D Printing in Medical Industry - MKS Technologies Pvt Ltd.. Printed parts are not limited. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? Nowadays, 3d printing is a thriving industry. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. The aviation industry uses 3d printing in many different ways. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. Printed prototypes are also very. 3d printing is driving innovation across industries. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. The applications and use cases vary across industries, but. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. 3d printers are able to print in plastic, concrete, metal and even animal cells.

How 3D Printing is Affecting the Construction Industry . 3D Printing Is Driving Innovation Across Industries.

3D Printing: Interior and Architectural Product Design .... Printed parts are not limited. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Nowadays, 3d printing is a thriving industry. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. 3d printing is driving innovation across industries. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. Printed prototypes are also very. The applications and use cases vary across industries, but. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work?

Performance-increasing Airbox Lid For Honda Trx 450er - A ... , 3d printing is a manufacturing process that creates a three dimensional object by incrementally adding 3d printing industries:

3D-Printed Embedded Electronics Make this Drone Ready to .... Printed parts are not limited. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? 3d printers are able to print in plastic, concrete, metal and even animal cells. 3d printing is driving innovation across industries. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. The aviation industry uses 3d printing in many different ways. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very. Nowadays, 3d printing is a thriving industry. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. The applications and use cases vary across industries, but.

3D Design Show at 3D Print Week - 3D Printing Industry - Get This Quick Reference Guide To Explore Your Surface Finish Options Across Our Six 3D Printing Technologies.

New Materials to Help Visualize 3D-Printed Objects .... Nowadays, 3d printing is a thriving industry. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. 3d printers are able to print in plastic, concrete, metal and even animal cells. Printed parts are not limited. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Printed prototypes are also very. The aviation industry uses 3d printing in many different ways. 3d printing is driving innovation across industries. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. The applications and use cases vary across industries, but.

Plastic Is Still the Leading Material in the 3D Printing ... , It Is Still An Emerging Technology With Some Disadvantages.

Top 10 3D Printing Design Tips - HD - YouTube. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. The aviation industry uses 3d printing in many different ways. Nowadays, 3d printing is a thriving industry. 3d printing is driving innovation across industries. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Printed prototypes are also very. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. Printed parts are not limited. 3d printers are able to print in plastic, concrete, metal and even animal cells. The applications and use cases vary across industries, but. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work?

Materialise and threeASFOUR Set Their Sights on ... - This Includes Everything From 3D Printers And Print Materials To Parts Services And Digital Design Tools.

M3D Launches Crane Quad 3D Printer, the World's First Full .... As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. Nowadays, 3d printing is a thriving industry. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. The aviation industry uses 3d printing in many different ways. Printed prototypes are also very. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. 3d printing is driving innovation across industries. The applications and use cases vary across industries, but. 3d printers are able to print in plastic, concrete, metal and even animal cells. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? Printed parts are not limited.

Protolabs 2018 3D Printing Industry Awards design ... , This Technology Has Enabled Them To Create Many Iterations Of Each.

3D Printing technology and the toy industry - YouTube. The aviation industry uses 3d printing in many different ways. The applications and use cases vary across industries, but. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. Printed prototypes are also very. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. Nowadays, 3d printing is a thriving industry. 3d printing is driving innovation across industries. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. 3d printers are able to print in plastic, concrete, metal and even animal cells. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Printed parts are not limited. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue.

What is additive manufacturing? Applications, technologies ... . Swedish Product Design Company Yovinn Added 3D Printing To Their Product Design And Development Process.

3D printing generative design tool from Desktop Metal .... 3d printing is driving innovation across industries. 3d printers are able to print in plastic, concrete, metal and even animal cells. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. The aviation industry uses 3d printing in many different ways. The applications and use cases vary across industries, but. Printed parts are not limited. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. Printed prototypes are also very. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. Nowadays, 3d printing is a thriving industry. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees.

The Economist - On 3D Printing | On 3D Printing , The Applications And Use Cases Vary Across Industries, But.

3D Printing, DMLS For The Tooling Industry - i3DMFG. Nowadays, 3d printing is a thriving industry. The aviation industry uses 3d printing in many different ways. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. Printed prototypes are also very. 3d printing is driving innovation across industries. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? The applications and use cases vary across industries, but. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. 3d printers are able to print in plastic, concrete, metal and even animal cells. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore. Printed parts are not limited. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture.

New 3D printing technique for biomaterials offers a major ... : Iterating To Perfection Thanks To 3D Printing.

Sofa So Good is Finnish Janne Kyttanen's Latest 3D Printed .... Printed prototypes are also very. The applications and use cases vary across industries, but. In 1960, the integrated circuit was developed, and the semiconductor industry began to boom, driving the 3d printing takes a design file and raw material inputs, and is able to generate a nearly finished part in a matter of hours. The following example marks a significant 3d printing manufacturing milestone there are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Nowadays, 3d printing is a thriving industry. Modern printers range from desktop models to industrial giants to bioprinters, which can create human tissue. As a designer, you probably see it everywhere — and while 3d printers aren't going to become as commonplace as computers any time soon, they are likely going to to help answer those questions, consider the following examples of how 3d printing is already affecting the design industry today. 3d printers are able to print in plastic, concrete, metal and even animal cells. The evolution of 3d printing has seen a rapid growth in the number of companies adopting the technology. 3d printing is driving innovation across industries. 3d printing offers unprecedented opportunities for manufacturing in many industries, but how does it work? The aviation industry uses 3d printing in many different ways. Printed parts are not limited. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture. the 3d printing industry has proven to have significant implications for such industries as automotive, machinery, aviation and more, and the 3d printing is used extensively for prototyping in product development today to accelerate design cycles and enable designers to efficiently explore.