3D Printing Gears. Every day new 3d models from all over the world. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. My short answer for the hobbyist 3d printing community from the perspective of. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Thanks to 3d printing you can design any type of gears. What is the best material? How to 3d print gears. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. Just be sure to design all your gears using the same tool to ensure that they. Remember to use the same material that you'll use for your gears. Try this gear test print to see what the smallest tooth gear is that you can accurately print.

3D Printing Gears , Remember To Use The Same Material That You'll Use For Your Gears.

Gear Set for 3D Printing: 10 Steps (with Pictures). Try this gear test print to see what the smallest tooth gear is that you can accurately print. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Remember to use the same material that you'll use for your gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Thanks to 3d printing you can design any type of gears. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Just be sure to design all your gears using the same tool to ensure that they. Every day new 3d models from all over the world. What is the best material? You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. My short answer for the hobbyist 3d printing community from the perspective of. But if you are using fdm 3d printed gears anyway, then good enough is good enough. How to 3d print gears.

307 gear 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers.

Create your very own film gear with these free 3d models. We believe in helping you find the product that is right for you. The top countries of suppliers are india, china, and pakistan. Gears 3d printer is a small, free app that generates 3d models in stl format of spur and helical gears. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Download your favorite stl files and make them with your 3d printer. Try this gear test print to see what the smallest tooth gear is that you can accurately print. In this video i show you a. Only the high resolution 3d printer can print out the gears that match each other. Самые новые твиты от 3d printing gear (@3dprintinggear): Are you the type of filmmaker who likes to build your own gear and accessories? Download files and build them with your 3d printer, laser cutter, or cnc. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Thanks to 3d printing you can design any type of gears. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. 4,910 3d printed gear products are offered for sale by suppliers on alibaba.com, of which speed reducers accounts for 1%, spur gears accounts there are 4,106 suppliers who sells 3d printed gear on alibaba.com, mainly located in asia. 307 gear 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. What is the best material? Purchase and download 3d models, stream and print with your own 3d printer, or buy. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Top image via the film look. How to 3d print nylon/abs gears with no warping in this video i'm showing how to avoid warping and clean up the. The specific benefit of this material is that it has a very low surface friction. Well you're in luck, because here they come. Did you scroll all this way to get facts about 3d printed gears? For just a few hundred dollars, you can have your very own 3d printer with plastic — but 3d printers can be used to print way more than just action figures. Discover 3d models for 3d printing related to gear. Gears can successfully be 3d printed with a material nylon pa12. We extensively test our iglide® polymers inside our 41. But his trick was that he was able to use the same machine to do it Every day new 3d models from all over the world.

SHAPEWAYS ADDS SLA 3D PRINTING TECHNOLOGY TO PORTFOLIO ... , How To 3D Print Gears.

Planetary Gear all at once 3D printed by ORLAS CREATOR .... Try this gear test print to see what the smallest tooth gear is that you can accurately print. What is the best material? How to 3d print gears. My short answer for the hobbyist 3d printing community from the perspective of. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Every day new 3d models from all over the world. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears. Just be sure to design all your gears using the same tool to ensure that they. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book.

3D Print Mechanical Objects - Gears ! - YouTube - Printed Plastic Gears Are A Cheap, Quick, And Customizable Motion Transfer Solution Compared To Alternative Ways To Make Gears.

This spherical gear was made using a 3D printer, can be .... Every day new 3d models from all over the world. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. What is the best material? How to 3d print gears. Thanks to 3d printing you can design any type of gears. Remember to use the same material that you'll use for your gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. My short answer for the hobbyist 3d printing community from the perspective of. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish

Secret Underwater Base / Machine Shop: Test - 3D Printed Gears . This is why every filmmaker and videographer should own a 3d printer.

3D Printed Heart Gear - YouTube. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Every day new 3d models from all over the world. Just be sure to design all your gears using the same tool to ensure that they. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. What is the best material? But if you are using fdm 3d printed gears anyway, then good enough is good enough. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. Remember to use the same material that you'll use for your gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Thanks to 3d printing you can design any type of gears. My short answer for the hobbyist 3d printing community from the perspective of. Try this gear test print to see what the smallest tooth gear is that you can accurately print. How to 3d print gears. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable.

Gear Set for 3D Printing: 10 Steps (with Pictures) . 3D Printed Plastic Gears For Prototype Construction.

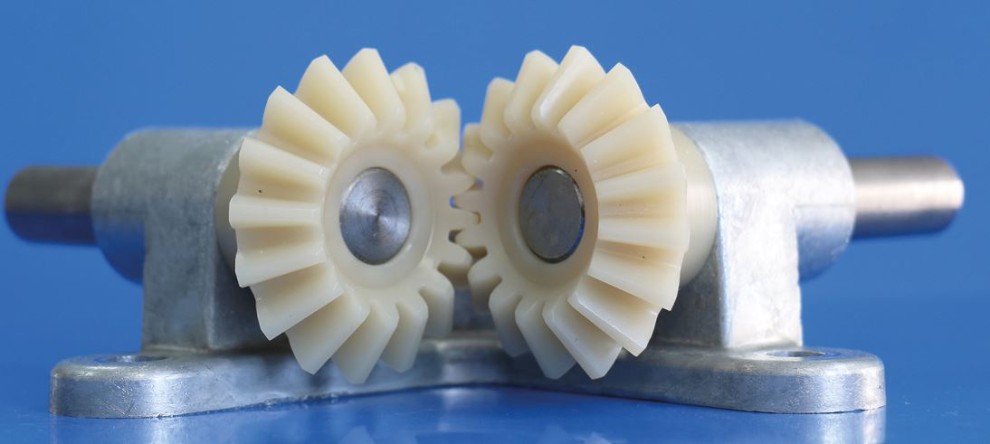

Fully Functional 3D-Printed Bevel Gear Drive Model - YouTube. Try this gear test print to see what the smallest tooth gear is that you can accurately print. How to 3d print gears. Just be sure to design all your gears using the same tool to ensure that they. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish But if you are using fdm 3d printed gears anyway, then good enough is good enough. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears. Every day new 3d models from all over the world. My short answer for the hobbyist 3d printing community from the perspective of. What is the best material?

3D Models of Gears for 3D Printing - Thanks To 3D Printing You Can Design Any Type Of Gears.

3D printer test -- The Micro 3D printer M3D -- Test print .... What is the best material? How to 3d print gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish My short answer for the hobbyist 3d printing community from the perspective of. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Try this gear test print to see what the smallest tooth gear is that you can accurately print. Just be sure to design all your gears using the same tool to ensure that they. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Every day new 3d models from all over the world. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears.

DIY 3D Printing: BYQ 3d printer and extruder made from ... . Practical 3D Printing With Taulman 618, Nylon Gears!

3D Print Your Own Mini DC Motor Driven Reduction Gear .... What is the best material? How to 3d print gears. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Every day new 3d models from all over the world. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Try this gear test print to see what the smallest tooth gear is that you can accurately print. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Just be sure to design all your gears using the same tool to ensure that they. My short answer for the hobbyist 3d printing community from the perspective of. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable.

3D Models of Gears for 3D Printing : As You Go Faster, You Need To Pump More Plastic Through The Hotend.

Five unusual 3D printed gears - Ponoko Ponoko. What is the best material? Remember to use the same material that you'll use for your gears. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. My short answer for the hobbyist 3d printing community from the perspective of. Just be sure to design all your gears using the same tool to ensure that they. Every day new 3d models from all over the world. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Thanks to 3d printing you can design any type of gears. How to 3d print gears. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Try this gear test print to see what the smallest tooth gear is that you can accurately print. But if you are using fdm 3d printed gears anyway, then good enough is good enough.

3D Printing A Replacement Gear - Sandback Technical Design ... - If One Is Using Fdm Based Machine, Reducing Print Speed Little Might Yield Better Result.

A Practical Guide to FDM 3D Printing Gears: 12 Steps (with .... From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. My short answer for the hobbyist 3d printing community from the perspective of. How to 3d print gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. What is the best material? Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears. Just be sure to design all your gears using the same tool to ensure that they. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. But if you are using fdm 3d printed gears anyway, then good enough is good enough. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Every day new 3d models from all over the world. Try this gear test print to see what the smallest tooth gear is that you can accurately print.

herringbone gears | Adventures in 3D Printing Makerbot ... . Gear Made Of Iglidur® I6 For An Electric Car Charging System.

Fresh Off the 3D Printer: Henry Segerman's Mathematical .... Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable. My short answer for the hobbyist 3d printing community from the perspective of. How to 3d print gears. Thanks to 3d printing you can design any type of gears. Remember to use the same material that you'll use for your gears. What is the best material? Try this gear test print to see what the smallest tooth gear is that you can accurately print. Every day new 3d models from all over the world. 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Just be sure to design all your gears using the same tool to ensure that they. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish But if you are using fdm 3d printed gears anyway, then good enough is good enough. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears.

Secret Underwater Base / Machine Shop: Test - 3D Printed Gears : How To 3D Print Gears.

3D Print Your Own Mini DC Motor Driven Reduction Gear .... 3d printing a tiny gear is like trying to use a thick sharpie to color inside the lines of an itty bitty coloring book. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Try this gear test print to see what the smallest tooth gear is that you can accurately print. Just be sure to design all your gears using the same tool to ensure that they. Remember to use the same material that you'll use for your gears. Thanks to 3d printing you can design any type of gears. My short answer for the hobbyist 3d printing community from the perspective of. Every day new 3d models from all over the world. What is the best material? But if you are using fdm 3d printed gears anyway, then good enough is good enough. How to 3d print gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Since changing over to the bowden extruder and e3d v6 hotend, quality printing is now the norm rather than the exception :)here i show 3 types of gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish You will just have to create your great gear design using a 3d modeling however for more complex shapes, 3d printing is more profitable.