3D Printing Fastest Infill. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. And from a printing perspective, it saves valuable time! If you are having trouble producing strong. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. This shape is the most efficient infill and fastest to print, the goto infill for most things. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Honeycomb infill cura is not currently available. Concentric is 2nd best to wave for flexible prints to keep it. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Grid / rectangular is a good default, fast option. This allows it to print faster while still feeling heavy enough. Infill can look cool, add strength, and save money, but it all depends on the print.

3D Printing Fastest Infill : .Advantages Gyroid Infill Prints Relatively Fast With Respect To Some Other Infill Types And Is Close To Isotropic (I.e.

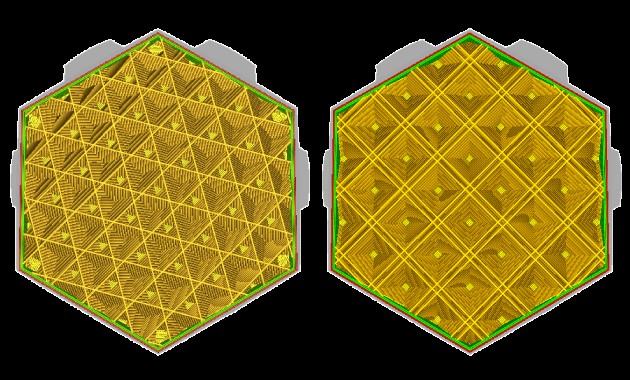

3D Printing Infill - The Basics Simply Explained | All3DP. And from a printing perspective, it saves valuable time! Infill can look cool, add strength, and save money, but it all depends on the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. This allows it to print faster while still feeling heavy enough. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Honeycomb infill cura is not currently available. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. If you are having trouble producing strong. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Concentric is 2nd best to wave for flexible prints to keep it. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Grid / rectangular is a good default, fast option. The infill inside your 3d printed part plays a very important role in the overall strength of your model.

Shell and infill properties impact the performance and cost of fdm 3d printing.

The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. Infill percentage in 3d printing. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even eliminate oozing and. Learn how to optimize these features for your 3d printed part. Basically the final 3d printed model will have different infill densities depending on the region of the model. Grid / rectangular is a good default, fast option. Stefan of cnc kitchen does a lot of 3d printer technique testing. What is the best infill pattern for. Consider a print with low infill that is going to be drilled and then screwed to another surface. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. .advantages gyroid infill prints relatively fast with respect to some other infill types and is close to isotropic (i.e. The fastest 3d printers can reduce lead time and increase productivity which makes it very appealing to 3d printing services. And from a printing perspective, it saves valuable time! As you can see, you can change the infill several times during printing and make sure that your figurine or model is sturdy enough even with. Uniform in all orientations), meaning that is very suitable for flexible prints. Say it 5 times fast! This allows it to print faster while still feeling heavy enough. The filament doesn't hang from the nozzle. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. But different infill geometries can be used for different needs. Though a consistent infill pattern and size is sufficient for some 3d prints, this parameter can limit the possibilities of other objects. But at least simplify3d tells me at some objects some slightly different estimated printing times. 💡 during print i only noticed little difference between the infill methods. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. What would be the best infill pattern for structural parts? If you're still not sure which way to go. This because (i think) any roughness caused by an higher speed during the infill, is flattened when printing slowly the perimeter. Honeycomb infill cura is not currently available. Consider 0% infill or infill where required if you are printing a model which has no strength. Low infill saves the material and speeds up the setting a faster retraction can prevent the filament from blobbing on the object as well as unintentional mixing.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly - Basically The Final 3D Printed Model Will Have Different Infill Densities Depending On The Region Of The Model.

Best 3D Printing Infill Pattern - 3dprintscape.com. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. This allows it to print faster while still feeling heavy enough. And from a printing perspective, it saves valuable time! Honeycomb infill cura is not currently available. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. This shape is the most efficient infill and fastest to print, the goto infill for most things. Concentric is 2nd best to wave for flexible prints to keep it. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Infill can look cool, add strength, and save money, but it all depends on the print. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Now why am i telling you all this and what do bees have to do with 3d printing anyway? If you are having trouble producing strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Grid / rectangular is a good default, fast option.

What is the Best Infill Pattern for 3D Printing? - 3DPrinterly : If You Were To Print Your Lithophane Using The Standard 20% Infill You Will See A.

3D Internal Structure For Better 3D Printed Objects | Hackaday. Infill can look cool, add strength, and save money, but it all depends on the print. Grid / rectangular is a good default, fast option. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Honeycomb infill cura is not currently available. This shape is the most efficient infill and fastest to print, the goto infill for most things. Concentric is 2nd best to wave for flexible prints to keep it. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. And from a printing perspective, it saves valuable time!

Infill Pattern Basics by @Simplify3D #3DPrinting ... : Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will.

Reprap development and further adventures in DIY 3D .... And from a printing perspective, it saves valuable time! This allows it to print faster while still feeling heavy enough. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Honeycomb infill cura is not currently available. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Now why am i telling you all this and what do bees have to do with 3d printing anyway? If you are having trouble producing strong. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Grid / rectangular is a good default, fast option. Infill can look cool, add strength, and save money, but it all depends on the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Concentric is 2nd best to wave for flexible prints to keep it. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used.

The Best Cura Infill Pattern (for Your Needs) | All3DP , Now Why Am I Telling You All This And What Do Bees Have To Do With 3D Printing Anyway?

Print Quality Troubleshooting Guide | Simplify3D (With .... Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. And from a printing perspective, it saves valuable time! Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Concentric is 2nd best to wave for flexible prints to keep it. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. If you are having trouble producing strong. Infill can look cool, add strength, and save money, but it all depends on the print. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. This shape is the most efficient infill and fastest to print, the goto infill for most things. Honeycomb infill cura is not currently available. Grid / rectangular is a good default, fast option. The infill inside your 3d printed part plays a very important role in the overall strength of your model. This allows it to print faster while still feeling heavy enough. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used.

Selecting the Best Infill Pattern for Your Next 3D ... - In Addition To This Tool, Smith Has Also Created What He Calls A Number Of Shells Display , Which Is Similar To The Infill Percentage Display, But Instead Of Showing Various Infill.

How to Choose an Infill for your 3D prints. Grid / rectangular is a good default, fast option. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. If you are having trouble producing strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Honeycomb infill cura is not currently available. This allows it to print faster while still feeling heavy enough. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Infill can look cool, add strength, and save money, but it all depends on the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Concentric is 2nd best to wave for flexible prints to keep it. And from a printing perspective, it saves valuable time! Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will.

True Transparent Parts From A Desktop 3D Printer | Hackaday : If You Are Having Trouble Producing Strong.

There are a lot of concepts within the desktop 3D printing .... Now why am i telling you all this and what do bees have to do with 3d printing anyway? Concentric is 2nd best to wave for flexible prints to keep it. This shape is the most efficient infill and fastest to print, the goto infill for most things. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. This allows it to print faster while still feeling heavy enough. Grid / rectangular is a good default, fast option. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. And from a printing perspective, it saves valuable time! Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. If you are having trouble producing strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill can look cool, add strength, and save money, but it all depends on the print. Honeycomb infill cura is not currently available.

3D Internal Structure For Better 3D Printed Objects | Hackaday - Printing At The Fastest Possible Setting.

The Best Cura Infill Pattern (for Your Needs) | All3DP. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Now why am i telling you all this and what do bees have to do with 3d printing anyway? This shape is the most efficient infill and fastest to print, the goto infill for most things. And from a printing perspective, it saves valuable time! If you are having trouble producing strong. Honeycomb infill cura is not currently available. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. This allows it to print faster while still feeling heavy enough. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. Grid / rectangular is a good default, fast option. Infill can look cool, add strength, and save money, but it all depends on the print. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Concentric is 2nd best to wave for flexible prints to keep it.

Best 3D Printing Infill Pattern - 3dprintscape.com : What Would Be The Best Infill Pattern For Structural Parts?

3D Printer Buying Guide - Boots Industries. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Honeycomb infill cura is not currently available. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. If you are having trouble producing strong. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. This shape is the most efficient infill and fastest to print, the goto infill for most things. Concentric is 2nd best to wave for flexible prints to keep it. Infill can look cool, add strength, and save money, but it all depends on the print. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. This allows it to print faster while still feeling heavy enough. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Grid / rectangular is a good default, fast option. And from a printing perspective, it saves valuable time!

Best 3D Printing Infill Pattern - 3dprintscape.com , There Are Several Infill Patterns But Not Only Does The Lines Pattern Or Cubic Subdivision Print Very Fast, It Uses A Low Amount Of Infill And Has Good Strength.

How to Choose an Infill for your 3D prints. Concentric is 2nd best to wave for flexible prints to keep it. Infill can look cool, add strength, and save money, but it all depends on the print. Honeycomb infill cura is not currently available. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. Now why am i telling you all this and what do bees have to do with 3d printing anyway? This shape is the most efficient infill and fastest to print, the goto infill for most things. Grid / rectangular is a good default, fast option. This allows it to print faster while still feeling heavy enough. If you are having trouble producing strong. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print. And from a printing perspective, it saves valuable time!

Download free 3D printer designs S hook with honey-cone ... . Though A Consistent Infill Pattern And Size Is Sufficient For Some 3D Prints, This Parameter Can Limit The Possibilities Of Other Objects.

How to Use 3D Print Infill Settings - Increase Strength .... This allows it to print faster while still feeling heavy enough. And from a printing perspective, it saves valuable time! Much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will. If you are having trouble producing strong. Infill can look cool, add strength, and save money, but it all depends on the print. This shape is the most efficient infill and fastest to print, the goto infill for most things. Different 3d print infill types, or infill patterns, can affect the object's final strength without changing the print's weight or filament used. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. The infill is responsible for connecting the outer other patterns like rectilinear and fast honeycomb may sacrifice some strength for faster printing speeds. Concentric is 2nd best to wave for flexible prints to keep it. Honeycomb infill cura is not currently available. Grid / rectangular is a good default, fast option. Now why am i telling you all this and what do bees have to do with 3d printing anyway? Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of the print.