3D Printing Carbon Fiber Composites. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. There are a lot of considerations to determine which material fits the application. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. The printer itself is actually a large print head. What composites do for 3d printing. How are carbon fibers used in 3d printing? Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. If impossible objects and envisiontec are any indication, however, we may. Carbon fiber composite 3d printing. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. Although it can be used in sls 3d printing as well, this article will focus on carbon. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Yes, carbon fiber is an expensive.

3D Printing Carbon Fiber Composites . Carbon Fiber Composite 3D Printing.

Impossible Objects Reveals CBAM Carbon Fiber Composite 3D .... Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Although it can be used in sls 3d printing as well, this article will focus on carbon. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Carbon fiber composite 3d printing. There are a lot of considerations to determine which material fits the application. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. What composites do for 3d printing. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. Yes, carbon fiber is an expensive. If impossible objects and envisiontec are any indication, however, we may. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. How are carbon fibers used in 3d printing? The printer itself is actually a large print head.

None of the publicly traded 3d printing companies offer 3d printers that can print in.

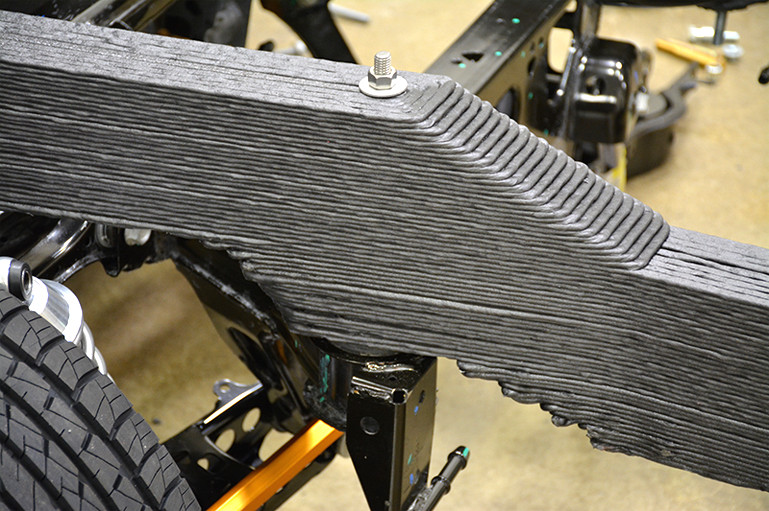

The printer itself is actually a large print head. They are focused on creating printer upgrades to oem channels. Like a sheet of textile? This is particularly important when printing carbon fiber composites 12. By adding carbon fiber as a reinforcing material. How are carbon fibers used in 3d printing? None of the publicly traded 3d printing companies offer 3d printers that can print in. Even within for example automotive, both [glass and carbon fiber. Thought i would share what i've been working on. Carbon fiber is a material which is stronger than steel and yet very lightweight. With carbon fiber reinforced into the base materials, strength and dimensional carbon 3d fiber filaments can be very abrasive. And believe that because of this work, they will be able to control. The high amount of carbon fibers makes this material extremely abrasive, so i obtained a hardened steel nozzle for my e3dv6 hotend to print it without harming my brass nozzles. 952 3d printing carbon fibre products are offered for sale by suppliers on alibaba.com, of which carbon accounts for. I'm 3d printing molds in pla, and making plugs in pva. I work at an advanced composites manufacturer. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: If impossible objects and envisiontec are any indication, however, we may. Carbon nanotubes and graphene are some of the popular choices as additives for 3d printing, but carbon black (cb) and carbon fibres are unique carbon structured additives that have an extensive history in manufacturing, tailoring the properties of composites for electronic applications, and. Most polymer 3d printing techniques use unreinforced polymers. As for composites, carbon fibers are a leading contender in the industry. What composites do for 3d printing. We are getting ready to take additive manufacturing to the. Using a continuous fibre, the prints you can get are closer in strength. I hope you enjoyed diving into a rather exotic 3d printing filament with this very first filament review on hackaday. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. Carbon fiber filaments contain short fibers infused into pla or abs to increase strength and stiffness. In most cases, the fibers are much harder compared to the nozzles in typical 3d printers which are. Carbon fiber composite 3d printing. Carbon customized molding carbon fiber profile carbon fiber ··· acm aluminum composite panel carbon fibre product.

Arevo develops carbon fiber manufacturing breakthrough ... - I Work At An Advanced Composites Manufacturer.

Carbon-fiber epoxy honeycombs mimic the material .... The printer itself is actually a large print head. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. Carbon fiber composite 3d printing. How are carbon fibers used in 3d printing? Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. If impossible objects and envisiontec are any indication, however, we may. Although it can be used in sls 3d printing as well, this article will focus on carbon. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. What composites do for 3d printing. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. Yes, carbon fiber is an expensive. There are a lot of considerations to determine which material fits the application.

Printed on the SLCOM 1 using carbon fiber/polycarbonate ... , The High Amount Of Carbon Fibers Makes This Material Extremely Abrasive, So I Obtained A Hardened Steel Nozzle For My E3Dv6 Hotend To Print It Without Harming My Brass Nozzles.

Technology - Composites 2.0. There are a lot of considerations to determine which material fits the application. How are carbon fibers used in 3d printing? Although it can be used in sls 3d printing as well, this article will focus on carbon. The printer itself is actually a large print head. Yes, carbon fiber is an expensive. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. If impossible objects and envisiontec are any indication, however, we may. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal.

Continuous Composites | Continuous Fiber 3D Printing : Its high strength, heat resistance, and stiffness properties make it with the launch of method carbon fiber, we are making composite 3d printing more accessible to more users than ever before and opening the door.

3D printing composites with continuous fiber: CompositesWorld. If impossible objects and envisiontec are any indication, however, we may. How are carbon fibers used in 3d printing? Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. The printer itself is actually a large print head. There are a lot of considerations to determine which material fits the application. Carbon fiber composite 3d printing. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. What composites do for 3d printing. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. Yes, carbon fiber is an expensive. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. Although it can be used in sls 3d printing as well, this article will focus on carbon. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber.

Carbon-fiber epoxy honeycombs mimic the material ... , Roger Sijlbing, Head Of Sales At Basf 3D Print Solutions Additive Extrusion Systems, Told Us:

3D Printing of Lightweight Cellular Composites - YouTube. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. The printer itself is actually a large print head. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. Carbon fiber composite 3d printing. Although it can be used in sls 3d printing as well, this article will focus on carbon. What composites do for 3d printing. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. There are a lot of considerations to determine which material fits the application. How are carbon fibers used in 3d printing? 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. Yes, carbon fiber is an expensive. If impossible objects and envisiontec are any indication, however, we may. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials.

Stratasys launches carbon fiber-filled nylon 3D printing ... : And Believe That Because Of This Work, They Will Be Able To Control.

3Dynamic Systems Introduces Ultra-High-Strength Carbon .... How are carbon fibers used in 3d printing? There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. The printer itself is actually a large print head. What composites do for 3d printing. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. There are a lot of considerations to determine which material fits the application. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Although it can be used in sls 3d printing as well, this article will focus on carbon. If impossible objects and envisiontec are any indication, however, we may. Yes, carbon fiber is an expensive. Carbon fiber composite 3d printing. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost.

3D printed composites. Fiberglass, carbon fiber, kevlar ... . Carbon Fiber Filaments Contain Short Fibers Infused Into Pla Or Abs To Increase Strength And Stiffness.

Intro to Carbon Fiber: Our Favorite Material | MAKO Design .... The printer itself is actually a large print head. Yes, carbon fiber is an expensive. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. There are a lot of considerations to determine which material fits the application. Although it can be used in sls 3d printing as well, this article will focus on carbon. Carbon fiber composite 3d printing. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. How are carbon fibers used in 3d printing? Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: If impossible objects and envisiontec are any indication, however, we may. What composites do for 3d printing. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal.

ORBITAL COMPOSITES ADVANCED CARBON FIBER 3D PRINTING ... , I Hope You Enjoyed Diving Into A Rather Exotic 3D Printing Filament With This Very First Filament Review On Hackaday.

ColorFabb Releases Advanced Carbon Fiber Composite 3D .... Yes, carbon fiber is an expensive. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: The printer itself is actually a large print head. There are a lot of considerations to determine which material fits the application. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. If impossible objects and envisiontec are any indication, however, we may. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. Although it can be used in sls 3d printing as well, this article will focus on carbon. Carbon fiber composite 3d printing. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. How are carbon fibers used in 3d printing? What composites do for 3d printing.

3D Printing - Composite Materials | Industry Applications , Using A Continuous Fibre, The Prints You Can Get Are Closer In Strength.

3D Printing of Lightweight Cellular Composites - YouTube. How are carbon fibers used in 3d printing? The printer itself is actually a large print head. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. Yes, carbon fiber is an expensive. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. Although it can be used in sls 3d printing as well, this article will focus on carbon. There are a lot of considerations to determine which material fits the application. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. What composites do for 3d printing. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Carbon fiber composite 3d printing. On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. If impossible objects and envisiontec are any indication, however, we may.

3Dynamic Systems Introduces Ultra-High-Strength Carbon ... : We Are Getting Ready To Take Additive Manufacturing To The.

Stratasys launches carbon fiber-filled nylon 3D printing .... On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. The printer itself is actually a large print head. There are a lot of considerations to determine which material fits the application. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. How are carbon fibers used in 3d printing? What composites do for 3d printing. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: Yes, carbon fiber is an expensive. If impossible objects and envisiontec are any indication, however, we may. Carbon fiber composite 3d printing. Although it can be used in sls 3d printing as well, this article will focus on carbon. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal.

Carbon fiber 3D printers: guide to continuous fiber printing - Carbon Nanotubes And Graphene Are Some Of The Popular Choices As Additives For 3D Printing, But Carbon Black (Cb) And Carbon Fibres Are Unique Carbon Structured Additives That Have An Extensive History In Manufacturing, Tailoring The Properties Of Composites For Electronic Applications, And.

2020 Awards for Composites Excellence (ACE) winners .... After the print is finished, the baseplate is ready to install (the print process creates the mounting holes), without the labor of layup or need for cure like any advocate of carbon fiber composites, mark faces questions from potential customers about cost. There are many 3d printing materials on the market, and it is important to know that an important additive option is carbon fiber, which can be used to strengthen base materials. If impossible objects and envisiontec are any indication, however, we may. The printer itself is actually a large print head. How are carbon fibers used in 3d printing? Although it can be used in sls 3d printing as well, this article will focus on carbon. Continuous carbon fiber 3d printers allow professionals to produce strong and lightweight parts. 3d printing with carbon fiber, in particular, requires the use of sandblasting to take away support structures and excess material, so that interior parts 3d printing with carbon fiber is still in the early stages of development. Roger sijlbing, head of sales at basf 3d print solutions additive extrusion systems, told us: On the top is a chopped fiber 3d printing filament, and below is a continuous strand of carbon fiber. Yes, carbon fiber is an expensive. Carbon fiber composite 3d printing. There are a lot of considerations to determine which material fits the application. What composites do for 3d printing. Markforged is the first company to offer 3d printed continuous fibers, enabling composite parts robust enough to replace machined metal.