3D Printing And Aluminum Casting. Printing wax for casting purposes, does anybody here have experience with that? With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. 3d printing has turned into the holy grail of additive manufacturing. Start out by printing your parts like you normally would. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. A truncated octahedron lattice 3d printed in aluminum source: How to 3d print aluminum. It's poised to kickstart a new renaissance in metal crafting and to change. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. This was the first time i had tried lost pla and it turned out. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger.

3D Printing And Aluminum Casting , And We Will Continue To Use 3D Printing And The Ultimaker To Deliver Benefits To Our Customers.

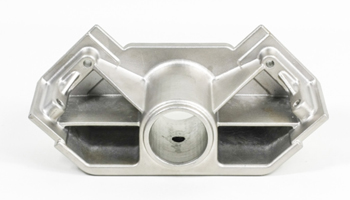

Producing large cast metal parts using 3D Printing .... myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. This was the first time i had tried lost pla and it turned out. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. It's poised to kickstart a new renaissance in metal crafting and to change. A truncated octahedron lattice 3d printed in aluminum source: However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. Printing wax for casting purposes, does anybody here have experience with that? How to 3d print aluminum. 3d printing has turned into the holy grail of additive manufacturing. Start out by printing your parts like you normally would.

The quality of parts that are 3d printed in aluminum are as good as parts manufactured.

Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. You can now cast your vote in the annual 3d printing industry awards. The material can be used for both prototyping and manufacturing purposes. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. Metal casting and 3d printing: Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. Aluminum 5052 aluminum 5754 copper c110 stainless steel 304 stainless steel 316l steel 1018. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. And we will continue to use 3d printing and the ultimaker to deliver benefits to our customers. Cloudddm is a company that operates like most 3d printing services where you can order parts through a web interface, but they're able. At a fraction of the cost of most additive manufacturing investment casting solutions, lulzbot 3d printers enable companies of all sizes to speed innovation. The advantages of each method of manufacturing are summarised and compared below. Presently, die casting encompasses many variant processes including squeeze casting and when it comes to design capabilities, 3d printing and die casting are somewhat specialized. This was the first time i had tried lost pla and it turned out. Aluminum qualifies as a universal material for 3d printing, say specialists in a project team formed by aviation supplier premium aerotec product developers have a wide range of aluminum alloys at their disposal for traditional manufacturing processes such as milling, turning, casting, forging and pressing. Die casting is not without similar capabilities, however. The top countries of suppliers are china, taiwan. Typically, aluminum is used for airplane seats, but magnesium is 35% lighter. Create a negative of the shape by subtracting it from a. By 3d printing molds for casting, the process has: When to use traditional metal casting. 3d systems is the only additive manufacturing company to offer a comprehensive additive investment casting solution, with dedicated products for every stage of your metal casting. Raise3d forum user caxton3d industry or trade: ··· 3d printer metal print aluminum metal 3d printing customized stainless steel prototyping aluminum titanium 3d printer metal rapid print there are 5,528 suppliers who sells metal casting 3d print on alibaba.com, mainly located in asia. As consumers become familiar with 3d printing, they often struggle with the complexity of the new technology. Instead, it has a matte gray finish with a slightly rougher and less defined for aluminum, we charge a minimum price per ordered piece. It's poised to kickstart a new renaissance in metal crafting and to change. Machined metal molds cost thousands of dollars to produce and take weeks of machining and polishing work. Even aside from its direct benefits, it also points to new ways of improving metal printing and curing the drawbacks present in the technology, as many companies have noted.

Casting Metal with 3D Printed Patterns | CTM Projects - Aluminum Is A Very Versatile Material And I Would Like To Promote The Awareness Of Aluminum Recycling Via Different Metal Casting Projects.

How to Make Metal Miniatures With 3D Printing | Formlabs. This was the first time i had tried lost pla and it turned out. A truncated octahedron lattice 3d printed in aluminum source: Start out by printing your parts like you normally would. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. 3d printing has turned into the holy grail of additive manufacturing. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. Printing wax for casting purposes, does anybody here have experience with that? In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. It's poised to kickstart a new renaissance in metal crafting and to change. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. How to 3d print aluminum. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting.

The world's first 3D printed aluminium guitar! - 3D ... , Sla And Wax 3D Printed Casting Patterns Significantly Reduce Delays And Costs For Casted Parts In The Digital Foundry.

Benefits of 3D Printing for Investment Casting .... 3d printing has turned into the holy grail of additive manufacturing. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. How to 3d print aluminum. It's poised to kickstart a new renaissance in metal crafting and to change. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. Printing wax for casting purposes, does anybody here have experience with that? Start out by printing your parts like you normally would. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum.

3D printer improvements: Molding and casting with a 3D printer . ··· 3d printer metal print aluminum metal 3d printing customized stainless steel prototyping aluminum titanium 3d printer metal rapid print there are 5,528 suppliers who sells metal casting 3d print on alibaba.com, mainly located in asia.

3D printer improvements: Molding and casting with a 3D printer. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. 3d printing has turned into the holy grail of additive manufacturing. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. Start out by printing your parts like you normally would. How to 3d print aluminum. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. Printing wax for casting purposes, does anybody here have experience with that? It's poised to kickstart a new renaissance in metal crafting and to change. This was the first time i had tried lost pla and it turned out. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. A truncated octahedron lattice 3d printed in aluminum source:

How to Sand Cast 3D Printed Objects: 12 Steps (with Pictures) - The Material Can Be Used For Both Prototyping And Manufacturing Purposes.

Lost PLA Casting. Creating aluminum or steel parts from 3D .... Printing wax for casting purposes, does anybody here have experience with that? A truncated octahedron lattice 3d printed in aluminum source: However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. This was the first time i had tried lost pla and it turned out. 3d printing has turned into the holy grail of additive manufacturing. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. It's poised to kickstart a new renaissance in metal crafting and to change. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. Start out by printing your parts like you normally would. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. How to 3d print aluminum. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum.

Newby RapidCast | Processes - Newby RapidCast , It's Poised To Kickstart A New Renaissance In Metal Crafting And To Change.

Producing low-cost cast metal parts using 3D Printing | 3D .... If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. Start out by printing your parts like you normally would. It's poised to kickstart a new renaissance in metal crafting and to change. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. A truncated octahedron lattice 3d printed in aluminum source: Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. 3d printing has turned into the holy grail of additive manufacturing. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. Printing wax for casting purposes, does anybody here have experience with that? This was the first time i had tried lost pla and it turned out. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. How to 3d print aluminum.

DIY Aluminum Investment Casting Using a 3d Printer.: 8 ... . Start Out By Printing Your Parts Like You Normally Would.

MadeSolid, Inc. Releases New Industry First FireCast Resin .... It's poised to kickstart a new renaissance in metal crafting and to change. Start out by printing your parts like you normally would. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. How to 3d print aluminum. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. This was the first time i had tried lost pla and it turned out. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. Printing wax for casting purposes, does anybody here have experience with that? A truncated octahedron lattice 3d printed in aluminum source: 3d printing has turned into the holy grail of additive manufacturing. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers.

Something Every 3D Printer Owner Should Have: A Foundry . Even Aside From Its Direct Benefits, It Also Points To New Ways Of Improving Metal Printing And Curing The Drawbacks Present In The Technology, As Many Companies Have Noted.

Metal Casting for Metal 3D Printing. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. How to 3d print aluminum. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. Start out by printing your parts like you normally would. 3d printing has turned into the holy grail of additive manufacturing. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. Printing wax for casting purposes, does anybody here have experience with that? With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. It's poised to kickstart a new renaissance in metal crafting and to change. This was the first time i had tried lost pla and it turned out. A truncated octahedron lattice 3d printed in aluminum source:

How to Cold Cast Your 3D Prints With Metal - The Material Can Be Used For Both Prototyping And Manufacturing Purposes.

How to Make Metal Miniatures With 3D Printing | Formlabs. Printing wax for casting purposes, does anybody here have experience with that? Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. 3d printing has turned into the holy grail of additive manufacturing. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. This was the first time i had tried lost pla and it turned out. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. It's poised to kickstart a new renaissance in metal crafting and to change. Start out by printing your parts like you normally would. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. A truncated octahedron lattice 3d printed in aluminum source: 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. How to 3d print aluminum.

Metal Casting with Your 3D Printer | Make: , When To Use Traditional Metal Casting.

Tethon 3D Launches Castalite® Investment Casting Resin. This was the first time i had tried lost pla and it turned out. How to 3d print aluminum. It's poised to kickstart a new renaissance in metal crafting and to change. Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. 3d printing has turned into the holy grail of additive manufacturing. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. Start out by printing your parts like you normally would. A truncated octahedron lattice 3d printed in aluminum source: Printing wax for casting purposes, does anybody here have experience with that? myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum. However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects.

DIY aluminum investment casting using a 3d printer. - 8 , Raise3D Forum User Caxton3D Industry Or Trade:

DIY Aluminum Investment Casting Using a 3d Printer.: 8 .... Ahhh… but printing in wax is a little bit of a problem as it isn't as available as 3d plastic printers. It's poised to kickstart a new renaissance in metal crafting and to change. 3d printing has turned into the holy grail of additive manufacturing. Start out by printing your parts like you normally would. A truncated octahedron lattice 3d printed in aluminum source: This was the first time i had tried lost pla and it turned out. How to 3d print aluminum. 3d printing a rotor out of pla and using the lost pla method to metal cast it in aluminum. With 3d printing, you need support material for steep overhangs, with casting, you need support (risers) to support the points of the model that are parallel with the bed, or are so this was our first attempt at aluminum casting, and it turned out okay at best, but we learned a lot about metal casting. In this video, youtuber myfordboy silently runs through the project of duplicating a metal part using 3d printing using a sand mold and casting aluminum. Aluminum is a metal with high strength, low weight that combines great mechanical and thermal properties. Printing wax for casting purposes, does anybody here have experience with that? However, the unk sculpture studio has a nice now we can use our makerbot replicator 3d printer to print just about any 3d model in abs or pla plastic and create aluminum and bronze objects. If you need a part to be accurate then you will have to account for extra shrinkage of the material you are casting with, in my case this is aluminum so i scaled the part about 2% larger and since the metal is shrinking the holes will actually get larger. myfordboy printed a new 3d printer extruder in pla and then used the lost pla method to cast it in aluminum.