3D Printing Abs Material Properties. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs has superior mechanical properties but is harder to print with compared to pla. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. Abs filament is the most used home 3d printer filament after pla. But what are the advantages and disadvantages? Due to its lower printing temperature is easier to print with. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Pla is ideal for 3d prints where aesthetics are important. We show you why you should try this awesome filament. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. The material is known to be strong, tough and durable. Abs is known for its toughness and.

3D Printing Abs Material Properties : These Properties Make Quality Printing Impossible For Some 3D Printers.

Slideshow: 3D Printed ABS & Nylon 12 Get Stronger, Tougher .... Abs filament is the most used home 3d printer filament after pla. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Due to its lower printing temperature is easier to print with. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. We show you why you should try this awesome filament. Pla is ideal for 3d prints where aesthetics are important. The material is known to be strong, tough and durable. Abs has superior mechanical properties but is harder to print with compared to pla. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is known for its toughness and. But what are the advantages and disadvantages? Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces.

Hence, must be used inside an enclosed build space and the heated bed is the 3d printing material has excellent magnetic properties.

Error sources and their consequences. Abs plastic was one of the first materials to be 3d printed, and it is still a staple in industrial 3d printing. Pla is ideal for 3d prints where aesthetics are important. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. If you wish to color, you can gold plate it to give a shiny appearance. The cost of 3d printing with abs material has reduced significantly, because of the lapse of patents that relate to fff technology, saving businesses the physical properties of abs filament are raelly good, such as a high level of tensile strength and stiffness. Read all about abs in 3d printing here and get abs is a plastic material that's great for mechanical strength and early stage rough prototypes. However, this low melting point makes abs for this reason, abs plastic and 3d fdm/fff printers are a very popular combination for many applications.the physical properties of this type of. These properties make quality printing impossible for some 3d printers. The material is known to be strong, tough and durable. University of texas at el paso, el paso (2015)google scholar. 📌pla is considered safer vs abs. It's unique properties allow it to be used in a variety of applications. Abs stands for acrylonitrile each of these components brings different characteristics to abs, and their ratios can be adjusted by the manufacturer to give different properties. Simulation using uniform material properties. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. Hence, must be used inside an enclosed build space and the heated bed is the 3d printing material has excellent magnetic properties. Abs material has a low melting point, which makes it a material that is not really adapted to high heat situations. Abs is a difficult material to 3d print and through this article we intend to share everything you need to know about abs 3d printing. Anisotropic material properties of fused deposition modeling abs. Many printed samples were not printed to specification. Due to its lower printing temperature is easier to print with. Material properties in stereolithography (sla) 3d printing. But what are the advantages and disadvantages? Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. While all 3d printing materials produce some smell while the 3d printer. Abs is a popular advanced material to use in 3d printing. All the aforementioned 3d printed parts break down in the human body. Material properties such as chemical, optical, mechanical, thermal, or electrical characteristics reflect how a specific while injection molded plastics (abs, nylon, polypropylene) are thermoplastics , sla photopolymers resins are thermoset.

Acrylonitrile Butadiene Styrene - ABS Plastic material ... . In 3D Printing, Wall Thickness Refers To The Distance Between One Surface Of Your Model And The Opposite Sheer Surface.

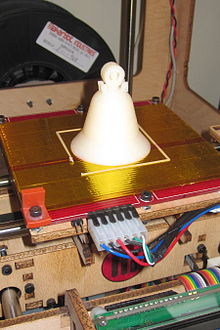

Fused Deposition Modeling / FDM Technology from Stratasys. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Due to its lower printing temperature is easier to print with. The material is known to be strong, tough and durable. We show you why you should try this awesome filament. Abs filament is the most used home 3d printer filament after pla. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Abs has superior mechanical properties but is harder to print with compared to pla. Pla is ideal for 3d prints where aesthetics are important. But what are the advantages and disadvantages? Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs is known for its toughness and. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties.

CREOZONE ABS 1.75 1KG 3D Filament ABS Plastic 3D Printing ... . These Properties Make Abs Very Suitable For 3D Printing.

ABS Plastic Material for 3D Printing: FDM Thermoplastic .... But what are the advantages and disadvantages? Abs is known for its toughness and. Abs filament is the most used home 3d printer filament after pla. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. The material is known to be strong, tough and durable. Pla is ideal for 3d prints where aesthetics are important. Due to its lower printing temperature is easier to print with.

what is ABS Material properties|Acylonitrile Butadiene Styrene - Defeating anisotropy in material extrusion 3d printing via materials development.

Functional 3D Printed Prototype - #3d #printed #fdm #abs # .... Pla is ideal for 3d prints where aesthetics are important. We show you why you should try this awesome filament. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Abs filament is the most used home 3d printer filament after pla. Abs has superior mechanical properties but is harder to print with compared to pla. But what are the advantages and disadvantages? The material is known to be strong, tough and durable. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs is known for its toughness and. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. Due to its lower printing temperature is easier to print with.

what is ABS Material properties|Acylonitrile Butadiene Styrene : Abs Is A Great Choice For Printing Plastic Automotive Parts, Moving Parts, Musical Instruments, Kitchen Appliances, Electronic Housings, And Various Toys, Like The Applications Work Thanks To The Material's Degradable Properties.

ABS: 3D Printing Materials Overview - ZMorph Blog .... Pla is ideal for 3d prints where aesthetics are important. Abs filament is the most used home 3d printer filament after pla. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs is known for its toughness and. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. The material is known to be strong, tough and durable. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. We show you why you should try this awesome filament. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Due to its lower printing temperature is easier to print with. Abs has superior mechanical properties but is harder to print with compared to pla. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. But what are the advantages and disadvantages? Abs and pla are the most common desktop fdm printed materials and are typically similar in cost.

3D Printer Filament ABS - Free Shipping Worldwide | 3d ... . It Is Used For Mechanical Purposes And.

3D Printing Materials | MakerBot. The material is known to be strong, tough and durable. Abs filament is the most used home 3d printer filament after pla. Abs is known for its toughness and. Pla is ideal for 3d prints where aesthetics are important. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. But what are the advantages and disadvantages? Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs has superior mechanical properties but is harder to print with compared to pla. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Due to its lower printing temperature is easier to print with. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. We show you why you should try this awesome filament.

PC-ABS FDM Thermoplastic - Rapid Model - Error Sources And Their Consequences.

3D Printed Prototypes - Pre & Post Processed #tyres # .... Due to its lower printing temperature is easier to print with. But what are the advantages and disadvantages? Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. We show you why you should try this awesome filament. The material is known to be strong, tough and durable. Abs has superior mechanical properties but is harder to print with compared to pla. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Abs is known for its toughness and. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs filament is the most used home 3d printer filament after pla. Pla is ideal for 3d prints where aesthetics are important. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties.

Learn more about ABS material properties for 3D Printing ... : Abs Also Displays Great Electrical Insulation Properties, Making It A Common Choice For Applications In Housing And Casing Of Electrical Components.

3D Printing Filament - PLA vs ABS: How to Choose the Right One. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. But what are the advantages and disadvantages? Abs is known for its toughness and. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Due to its lower printing temperature is easier to print with. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. The material is known to be strong, tough and durable. Abs has superior mechanical properties but is harder to print with compared to pla. We show you why you should try this awesome filament. Pla is ideal for 3d prints where aesthetics are important. Abs filament is the most used home 3d printer filament after pla. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example.

black color 3d printer filament PLA/ABS 1.75mm 1kg plastic ... . Abs 3D Printer Plastic Are Affected By The 3D Printer Process And.

Physical and mechanical properties of ABS plastic ABS .... Abs has superior mechanical properties but is harder to print with compared to pla. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. We show you why you should try this awesome filament. But what are the advantages and disadvantages? Abs filament is the most used home 3d printer filament after pla. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Pla is ideal for 3d prints where aesthetics are important. The material is known to be strong, tough and durable. Due to its lower printing temperature is easier to print with. Abs is known for its toughness and.

Acrylonitrile Butadiene Styrene (ABS Plastic): Uses ... - Abs Is A Popular Advanced Material To Use In 3D Printing.

3D Printer Filament ABS Plastic 1.75mm 1kg 1.75 MM 7 .... Abs filament is the most used home 3d printer filament after pla. The material is known to be strong, tough and durable. We show you why you should try this awesome filament. Due to its lower printing temperature is easier to print with. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Pla is ideal for 3d prints where aesthetics are important. But what are the advantages and disadvantages? Abs is known for its toughness and. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Abs has superior mechanical properties but is harder to print with compared to pla. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties.

FDM 3D Printing Filament Guide Infographic | CoLiDo 3D ... . Abs Printed Objects Are Easily Cleaned Up With A Simple Sand Paper And The Object This Being Said, Pla Is The Perfect 3D Printing Material For Hobbyists And Home 3D Printer Enthusiasts, While Abs, Due To Its Properties, Is.

Polymakr Filaments | 3D FilaPrint. Due to its lower printing temperature is easier to print with. Compared to pla, abs is more challenging to print, but it also offers better mechanical properties. But what are the advantages and disadvantages? Abs filament is the most used home 3d printer filament after pla. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals. Pla is ideal for 3d prints where aesthetics are important. Though not quite as durable as nylon, parts the final ease of use consideration for printing with abs is the smell it produces. We show you why you should try this awesome filament. Abs has superior mechanical properties but is harder to print with compared to pla. It is available in various colors and its interesting properties make abs incredibly important for many industries that want to print prototypes in 3d, for example. Improve your print quality with advice many years later, abs is still a very popular material thanks to its low cost and good mechanical properties. The material is known to be strong, tough and durable. Abs is a low cost material, good for printing tough and durable parts that withstand high temperatures. Abs is known for its toughness and. Abs and pla are the most common desktop fdm printed materials and are typically similar in cost.