3D Printer Using Plastic Pellets. By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. There are other benefits that come from printing with pellets. In this tech tuesday episode, tom and tracy hazzard explain the. A kilogram of plastic pellets costs less than a tenth of that. I found this pellet extruder. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: Why is using plastic pellets directly for 3d printing a good idea? Does anyone have a solution to this problem? If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive.

3D Printer Using Plastic Pellets , Everplast Expect The New Pellet Extrusion 3D Printers Become An Industrial Revolution Product In This Field Since We Have Received Orders From Customers In European And Will.

DIY 3D Printing: Erectorbot large volume 3d printer and .... It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. Why is using plastic pellets directly for 3d printing a good idea? Does anyone have a solution to this problem? In this tech tuesday episode, tom and tracy hazzard explain the. A kilogram of plastic pellets costs less than a tenth of that. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. I found this pellet extruder. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. There are other benefits that come from printing with pellets. By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems.

Regular filament is made by extruding i really want a 1 meter cubed printer with a 5mm nozzle and a pellet extruder.

Hp filament this flexible filament can be used with general 3d printers. A wide variety of pla plastic pellet 3d printer options are available to you, such as warranty of core components, condition, and local service location. Hp filament this flexible filament can be used with general 3d printers. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. A few months back i asked the question on g+, would anyone like to discuss pellet / granular extruders? The benefits of using an airwolf 3d printer model: By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. But because it sticks so well this plastic is just like any other, you just need to adhere to the few best practices when printing and. I found this pellet extruder. Another benefit of using pellets for 3d printing is the higher outputs than filament based machines. Petg plastic makes a terrible support structure, because it sticks so well. Aw3d v.5 while reviewing these features, please understand that all printed. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. Wondering what materials to use for your 3d printing project? If your kids leave their legos out one too many times for you not only is this great for the environment, but the team says it will save you a fortune in filament costs for your 3d printing. Everplast expect the new pellet extrusion 3d printers become an industrial revolution product in this field since we have received orders from customers in european and will. Printing with pellets offers quite a few benefits. Glad to see a pellet. It's not the cheapest printing material you'll ever find and you're limited to what filament makers offer in terms of materials and rather than feeding from a cartridge, the pellets are poured into a hopper for use in the printing process. Plastic products are generally made with fdm printers, in which thermoplastic. We have designed the best pellet head extrude on the market. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. Hp filament is a very flexible filament produced by our compound technology. Using pellets materials for 3d printing is cheaper than using filaments reducing operational and part cost. The strooder is a plastic repurposing machine designed to gobble plastic pellets and spit them back out as filament for use in a 3d printer. I am interested in this method of printing and would like nal how it worksrather than using filament, this miniaturized direct drive system accepts pelletized plastic that is pulled down from a hoppe. Currently, 3d printing filament is produced by melting down plastic pellets, extruding the melted plastic using pellets, however, eliminates the need for further processing, and, therefore, makes them much cheaper. In this tech tuesday episode, tom and tracy hazzard explain the. The heated bed can significantly improve. If so what did you think of it? We explain the benefits of each of the materials that can be the materials used for 3d printing are as diverse as the products that result from the process.

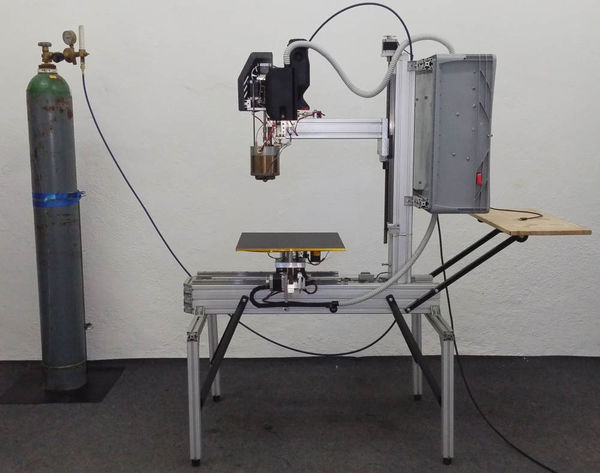

Pellet Extruder for 3D printer almost ready to go - YouTube : 3D Printing Continues To Amaze Us With Regular Developments Happening In Start Ups And Bigger Organizations.

New Zealand Researchers Develop and Characterize Micro .... 3d printing with plastic pellets has several benefits which include faster print times and lower cost. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. In this tech tuesday episode, tom and tracy hazzard explain the. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: A kilogram of plastic pellets costs less than a tenth of that. There are other benefits that come from printing with pellets. I found this pellet extruder. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. Why is using plastic pellets directly for 3d printing a good idea? By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. Does anyone have a solution to this problem?

3D Printing with Recycled Plastic Pellets: Gigabot X ... : These Filaments, However, Are Typically Made From Plastic Pellets, So An Ohio Company Called Sculptify Thought:

3D Printing pellet extruder screw and barrel - RobotDigg. In this tech tuesday episode, tom and tracy hazzard explain the. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. There are other benefits that come from printing with pellets. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. A kilogram of plastic pellets costs less than a tenth of that. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. Why is using plastic pellets directly for 3d printing a good idea?

David, the 3D Pellet Printer from Sculptify - 3D Printing ... . The heated bed can significantly improve.

Direct 3D printing pellet extruder2 with pre heating .... By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. A kilogram of plastic pellets costs less than a tenth of that. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. Why is using plastic pellets directly for 3d printing a good idea? These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: In this tech tuesday episode, tom and tracy hazzard explain the. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. I found this pellet extruder. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. Does anyone have a solution to this problem? It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. There are other benefits that come from printing with pellets.

Gigabot X can 3D Print with Recycled Plastic Pellets | All3DP , Although These Surfaces Might Work Fine For Petg, We Recommend Using A Heated Build Platform For Best Results.

Gigabot X: Large-Scale, Recycled Plastic Pellet 3D Printer .... It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: A kilogram of plastic pellets costs less than a tenth of that. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. Why is using plastic pellets directly for 3d printing a good idea? Does anyone have a solution to this problem? Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. There are other benefits that come from printing with pellets. By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. In this tech tuesday episode, tom and tracy hazzard explain the. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. I found this pellet extruder.

Micro Extruder Can Run Normal-Sized Pellets for 3D ... - Ideal For Use In Home Extruders Such As The Noztek, Filastruder, And.

MakiBox Pellet Extruder First Looks - YouTube. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. A kilogram of plastic pellets costs less than a tenth of that. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: Why is using plastic pellets directly for 3d printing a good idea? By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. Does anyone have a solution to this problem? I found this pellet extruder. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. In this tech tuesday episode, tom and tracy hazzard explain the. There are other benefits that come from printing with pellets. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. 3d printing with plastic pellets has several benefits which include faster print times and lower cost.

Direct pellet 3D Printing extruder 1 - YouTube . Hp Filament Is A Very Flexible Filament Produced By Our Compound Technology.

Sculptify's FLEX: Pellets Instead of Filament - 3D .... If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. In this tech tuesday episode, tom and tracy hazzard explain the. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. A kilogram of plastic pellets costs less than a tenth of that. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. Why is using plastic pellets directly for 3d printing a good idea? There are other benefits that come from printing with pellets. Does anyone have a solution to this problem? It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. I found this pellet extruder.

DIY 3D Printing: Erectorbot large volume 3d printer and ... - If Your Kids Leave Their Legos Out One Too Many Times For You Not Only Is This Great For The Environment, But The Team Says It Will Save You A Fortune In Filament Costs For Your 3D Printing.

New DeltaWasp Pellet 3D Printer Prints Big Without Big .... This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. There are other benefits that come from printing with pellets. 3d printing with plastic pellets has several benefits which include faster print times and lower cost. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. A kilogram of plastic pellets costs less than a tenth of that. Why is using plastic pellets directly for 3d printing a good idea? These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. In this tech tuesday episode, tom and tracy hazzard explain the. I found this pellet extruder. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. Does anyone have a solution to this problem? 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations.

Pam is a pellet-based 3D printer able to print four ... : Using Pellets Materials For 3D Printing Is Cheaper Than Using Filaments Reducing Operational And Part Cost.

Quality Plastic Pellet Extruder & Plastic Recycling .... There are other benefits that come from printing with pellets. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. Why is using plastic pellets directly for 3d printing a good idea? Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. A kilogram of plastic pellets costs less than a tenth of that. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. I found this pellet extruder. In this tech tuesday episode, tom and tracy hazzard explain the. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: Does anyone have a solution to this problem? By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. 3d printing with plastic pellets has several benefits which include faster print times and lower cost.

John's Model Making: 3D Printing Pellet Funnel - The Advantage Of Using Pellets Is That We Could Use Various Materials, Even Mix Different Materials Together For Printing.

PLA Pellets for 3D printing for making your own PLA .... For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. I found this pellet extruder. By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: A kilogram of plastic pellets costs less than a tenth of that. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. There are other benefits that come from printing with pellets. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. Why is using plastic pellets directly for 3d printing a good idea? In this tech tuesday episode, tom and tracy hazzard explain the. Does anyone have a solution to this problem? 3d printing with plastic pellets has several benefits which include faster print times and lower cost.

The dark side of 3D printing: 10 things to watch ... , Depending On The Material This Extruder Can Reach Outputs Of Up To 12Kg/Hr.

Pam is a pellet-based 3D printer able to print four .... By bypassing the process by which pellets are converted to filament, a 3d printing right now, commercially available pellet printers are only used for large manufacturing systems. Discussing a 3d printing with pellets project using a delta wasp printer and how it was used to create full sized chairs. These filaments, however, are typically made from plastic pellets, so an ohio company called sculptify thought: A kilogram of plastic pellets costs less than a tenth of that. 3d printing continues to amaze us with regular developments happening in start ups and bigger organizations. I found this pellet extruder. There are other benefits that come from printing with pellets. It eliminates the need for extruded plastic filament, for example, which tends to be about 10x more expensive than pelletized plastic. If traditional printers use ink and toner cartridges, most commercial 3d printers use plastic filament spools to create the objects you want. For 3d printing, the holy grail has been to print directly with affordable pellets instead of the expensive rolls of filament. In this tech tuesday episode, tom and tracy hazzard explain the. Why is using plastic pellets directly for 3d printing a good idea? Does anyone have a solution to this problem? 3d printing with plastic pellets has several benefits which include faster print times and lower cost. This whole area needs more development and a focus from the while experimenting with different materials and plastic pellets i designed two different motor drive.