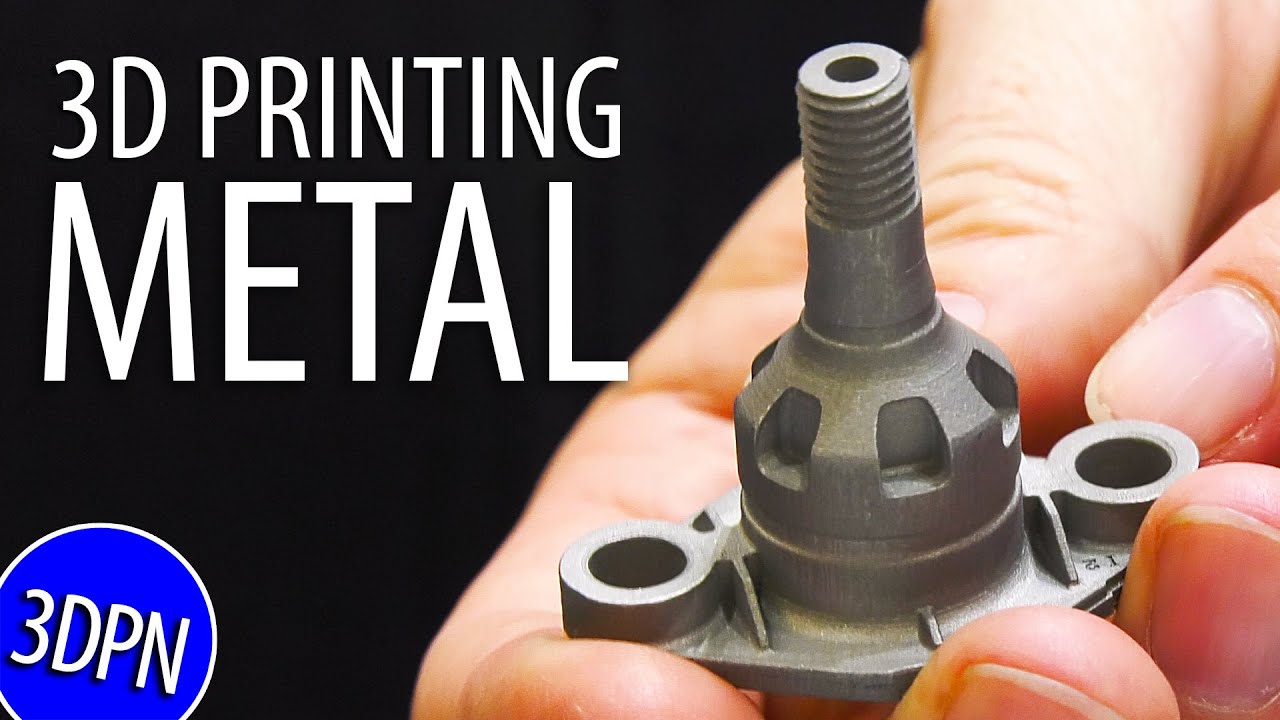

3D Printer Using Metal. Anzalone, chenlong zhang, bas wijnen, paul g. 3d printing with metal can produce visually and physically impressive results. It's less commonly used than slm or dmls. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. Desktop metal | affordable metal 3d printing for the office. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. The printer uses filament that is filled with small, metal rods. This is done by mixing the metal powder together with the metal paste. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever.

3D Printer Using Metal , 3D Printing Metal Parts Has Never Been Simpler Than With The Metal X.

Desktop Metal close new financing round with Ford - 3D .... Anzalone, chenlong zhang, bas wijnen, paul g. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. It's less commonly used than slm or dmls. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. The printer uses filament that is filled with small, metal rods. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. This is done by mixing the metal powder together with the metal paste. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. Desktop metal | affordable metal 3d printing for the office. 3d printing with metal can produce visually and physically impressive results. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. The part is left porous, and must go in the furnace for its particles to fuse and densify the part.

3d printing with metal can produce visually and physically impressive results.

3d printing metal parts has never been simpler than with the metal x. In thermoplastic 3d printers, the material is melted in a chamber inside the hotend, then extruded through a nozzle to be deposited. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. Desktop metal | affordable metal 3d printing for the office. Selective laser melting (slm) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and material jetting operates in a similar fashion to 2d printers. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. These methods vary greatly, ranging from using. Seeing as i'm just printing abs at the moment, i decided to omit the layer cooling fan and purchased an e3d all metal clone. 3,208 3d printer using metal products are offered for sale by suppliers on alibaba.com, of which digital printers accounts for 53%, inkjet printers accounts for 13%, and machining accounts for 1%. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. Cheap 3d printers, buy quality computer & office directly from china suppliers:2020 newest idex 3d printer independent dual by continuing to use aliexpress you accept our use of cookies (view more on our privacy policy). Anzalone, chenlong zhang, bas wijnen, paul g. Although most of these applications are focused on corporate use cases, there are companies working on making it possible for consumers to 3d print with metal on their desktop printers. Metal 3d printing refers to the selective laser melting and direct metal laser sintering. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. Find here 3d printer, 3d printing machine manufacturers, suppliers & exporters in india. Atomic diffusion additive manufacturing prints your part using a bound metal. If the printer prints with standard pla, it will print with filamet™. Make custom products in plastic, metal, full color and more high quality 3d printing materials. 3d printing metal parts has never been simpler than with the metal x. It's less commonly used than slm or dmls. 3d metal printer manufacturers & suppliers. Get contact details & address of companies manufacturing and supplying 3d printer, 3d printing machine, three dimensional printer across india. 3d printing with metal can produce visually and physically impressive results. Find out how 3d printing metal works and how you can create designs infused with metal powder! With metal 3d printing on the rise, the number of available metal 3d printers on the market is expanding. Metal 3d printing & metal 3d printers: The history and categorization of pbf metal 3d printers get a bit messy and it mostly. These include perhaps the most notable, direct metal laser sintering , or dmls. Metal powder is the backbone of metal 3d printing. A standard welding nozzle matching the wire diameter is used as the electrode on the hot end, while a metal build plate serves as the other electrode.

Stainless Steel 3D Printing Material Information - Shapeways , This Is Done By Mixing The Metal Powder Together With The Metal Paste.

10 Best Metal 3D Printers - 3D Printer Review Site3D .... Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. 3d printing with metal can produce visually and physically impressive results. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. It's less commonly used than slm or dmls. The printer uses filament that is filled with small, metal rods. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Anzalone, chenlong zhang, bas wijnen, paul g. Desktop metal | affordable metal 3d printing for the office. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. This is done by mixing the metal powder together with the metal paste. The history and categorization of pbf metal 3d printers get a bit messy and it mostly.

MatterFab, Metal 3D Printing Startup Raises $5.75 M ... . A Standard Welding Nozzle Matching The Wire Diameter Is Used As The Electrode On The Hot End, While A Metal Build Plate Serves As The Other Electrode.

BASF Ultrafuse 316L - Tutorial for 3D printing using metal .... 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. This is done by mixing the metal powder together with the metal paste. It's less commonly used than slm or dmls. Anzalone, chenlong zhang, bas wijnen, paul g. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. The part is left porous, and must go in the furnace for its particles to fuse and densify the part.

Print with metal on an ordinary 3d printer with Filamet : 3,208 3d printer using metal products are offered for sale by suppliers on alibaba.com, of which digital printers accounts for 53%, inkjet printers accounts for 13%, and machining accounts for 1%.

Metal 3D printing takes flight - TechCrunch. Anzalone, chenlong zhang, bas wijnen, paul g. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. The printer uses filament that is filled with small, metal rods. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. 3d printing with metal can produce visually and physically impressive results. Desktop metal | affordable metal 3d printing for the office. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. It's less commonly used than slm or dmls. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. This is done by mixing the metal powder together with the metal paste. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance.

New in Metal 3D Printing: Copper | Blog | Stratasys Direct ... - 3D Printing, In Contrast, Uses Almost Precisely As Much Material As Is Present In The Actual Object, Bringing Wastage Down To Nothing Whatsoever.

MiniMetalMaker 3D Metal Printer Uses Liquid Metal Clay To .... 3d printing with metal can produce visually and physically impressive results. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Desktop metal | affordable metal 3d printing for the office. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. It's less commonly used than slm or dmls. This is done by mixing the metal powder together with the metal paste. The printer uses filament that is filled with small, metal rods. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. Anzalone, chenlong zhang, bas wijnen, paul g. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever.

TRINUS - The Affordable All-Metal 3D Printer » Gadget Flow , 3,208 3D Printer Using Metal Products Are Offered For Sale By Suppliers On Alibaba.com, Of Which Digital Printers Accounts For 53%, Inkjet Printers Accounts For 13%, And Machining Accounts For 1%.

Free Form Metal 3D Printer 3Doodler on Steroids - 3D .... Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. The printer uses filament that is filled with small, metal rods. Anzalone, chenlong zhang, bas wijnen, paul g. It's less commonly used than slm or dmls. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. This is done by mixing the metal powder together with the metal paste. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. 3d printing with metal can produce visually and physically impressive results. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Desktop metal | affordable metal 3d printing for the office. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting.

TRINUS - The Affordable All-Metal 3D Printer » Gadget Flow - The Metal X Has A Build Volume Of 300 Mm X 220 Mm X 180 Mm (Wdh) With An Enclosed Build Chamber.

3D Printing makes Stainless Steel 3X Stronger! - 3Dnatives. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Anzalone, chenlong zhang, bas wijnen, paul g. This is done by mixing the metal powder together with the metal paste. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. Desktop metal | affordable metal 3d printing for the office. It's less commonly used than slm or dmls. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. The printer uses filament that is filled with small, metal rods. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. 3d printing with metal can produce visually and physically impressive results. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries.

Introduction to metal 3D printing | 3D Hubs : Industrial Grade Nozzle Components, Perfect Shape, No Joint, Stable Flashforge 3D Printer Creator Pro, Metal Frame Structure, Acrylic Covers, Optimized Build Platform, Dual Extruder W/2 Spools, Works With Abs And.

HP's metal 3D printer is probably a MIM based metal .... 3d printing with metal can produce visually and physically impressive results. It's less commonly used than slm or dmls. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. This is done by mixing the metal powder together with the metal paste. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. Desktop metal | affordable metal 3d printing for the office. The printer uses filament that is filled with small, metal rods. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. Anzalone, chenlong zhang, bas wijnen, paul g. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance.

TRUMPF to Unveil New Metal 3D Printers - 3D Printing Industry , This Is Done By Mixing The Metal Powder Together With The Metal Paste.

Concept Laser Gets Materialise to Help with 3D Metal Printers. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. This is done by mixing the metal powder together with the metal paste. The printer uses filament that is filled with small, metal rods. Anzalone, chenlong zhang, bas wijnen, paul g. 3d printing with metal can produce visually and physically impressive results. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. It's less commonly used than slm or dmls. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. Desktop metal | affordable metal 3d printing for the office.

Testing 3D-printed Metal Parts For Space - SpaceRef . Metal Printers Can Be Used Of Small Batch Manufacturing, But The Capabilities Of Metal 3D Printing Systems Resemble More The Batch Manufacturing Capabilities Of Fdm Or Sla Machines Than That Of Sls Printers:

5 Big Breakthroughs to Anticipate in 3D Printing. It's less commonly used than slm or dmls. The printer uses filament that is filled with small, metal rods. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. Desktop metal | affordable metal 3d printing for the office. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. This is done by mixing the metal powder together with the metal paste. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. Anzalone, chenlong zhang, bas wijnen, paul g. 3d printing with metal can produce visually and physically impressive results. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting.

TRUMPF Unveils New Metal 3D Printers at formnext ... - Find Here 3D Printer, 3D Printing Machine Manufacturers, Suppliers & Exporters In India.

Metal 3D Printing Alternatives: Investment Casting & Sand .... It's less commonly used than slm or dmls. Desktop metal | affordable metal 3d printing for the office. Anzalone, chenlong zhang, bas wijnen, paul g. Metal is ideal for creating customized parts that are heat, chemical, and as the name suggests, this printer uses an electron beam to melt the metal, rather than a laser. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding applications found in the aerospace and automotive industries. The printer uses filament that is filled with small, metal rods. During debinding, the binding material (wax and polymer binders) is dissolved thanks to a proprietary liquid substance. However, companies are using another approach to manufacture affordable metal 3d printers based on binder jetting. The history and categorization of pbf metal 3d printers get a bit messy and it mostly. This is done by mixing the metal powder together with the metal paste. The part is left porous, and must go in the furnace for its particles to fuse and densify the part. 3d printing with metal can produce visually and physically impressive results. This mixture is then extruded using a pneumatic extrusion 3d printer to create the desired 3d object. Typically, these machines use metal powder as feedstock, forming a green shape with a binder before sintering in the past, a metal 3d printer would be the reserve of the production facility floor, research labs, and these metal 3d printers may have smaller build volumes than their production peers. 3d printing, in contrast, uses almost precisely as much material as is present in the actual object, bringing wastage down to nothing whatsoever.