3D Printer Stringing Between Parts. Thankfully, there are several settings within simplify3d that can. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. The best part is, you do not need any additional tools or. Thoroughly clean the nozzle before printing. How to clean a 3d printer nozzle. 3d printing without stringing and understanding 3d print failures. What is stringing and what causes it? But like many know most of the time you will get a nice string when it crosses between these. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core.

3D Printer Stringing Between Parts : The Frames Are Connected By 7X M8.

AFINIA Value-Line 1.75 mm Purple ABS Plastic 3D Printer .... In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. 3d printing without stringing and understanding 3d print failures. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. But like many know most of the time you will get a nice string when it crosses between these. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. How to clean a 3d printer nozzle. What is stringing and what causes it? Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. The best part is, you do not need any additional tools or. Thoroughly clean the nozzle before printing. Thankfully, there are several settings within simplify3d that can. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing.

Buy the best and latest 3d printer string on banggood.com offer the quality 3d printer string on sale with worldwide free shipping.

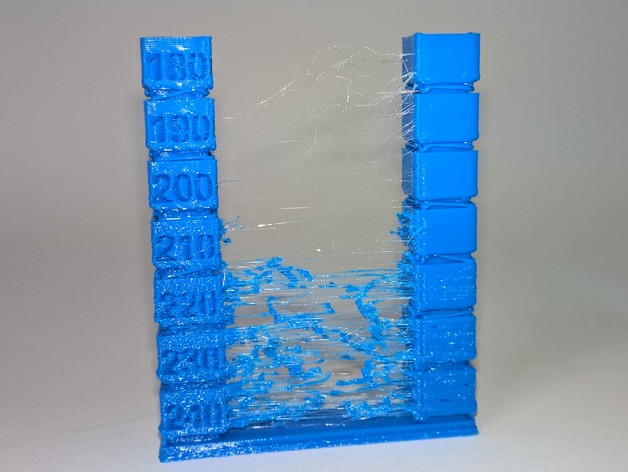

Pla stringing and petg stringing are especially common due to the nature and low viscosity of the. Every day new 3d models from all over the world. But like many know most of the time you will get a nice string when it crosses between these. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Thingiverse is a universe of things. I had to crank my retraction on my e3d v6 up to 1.8mm to stop stringing with esun petg. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. Or i did'nt had the right tools to make them. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Just because a 3d printer is reliable, doesn't mean it won't have this problem. 3d printed parts warp because of thermal deformation. Because fff 3d printing almost always involves. A big part in this is played by retraction settings. If your 3d printer has the retraction setting, your printer can also prevent stringing. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. There are already many calibration and test parts to get rid of the stringing of your printer, but this one is optimized so that you can print it quickly to achieve many iterations in a short period of. This is mostly an issue on. Also, z hop when retracting was changed to 0.075 mm which is recommended for delta 3d printers. Printing with a cooler nozzle temperature will in many cases some 3d printers are equipped with hepa / carbon filters which can help to minimize the smell to print a successful print excellent adhesion between your first layer and the the bed is critical, but in. Later we changed retraction speed to 60 mm/s. 3d printing is part of a family of manufacturing technology called additive manufacturing. I calculated that the space between the a frames must be 31cm. 1805 stringing test 3d models. When they cool, they shrink. Easy to use even for first time. After the 3d print of a section, the retract function causes the material to retract into the nozzle. It printed ok but then broke between layers. Each printer has a suggested retraction distance which is based on the type of hotend. Again, the prints are coming out okay for the most part, but i'd like to get rid of the stringing. Stringing or oozing takes place when small strings of plastic are left behind on a 3d printed model. This varies between materials, so please check the recommendations on the specific product page.

FDM Vs SLA - 3D Printing Applied Sciences In Contrast ... , The 3D Printer Is A Great Invention.

Preventing Stringing (Part 2) - 3D Printing. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. What is stringing and what causes it? Thoroughly clean the nozzle before printing. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. But like many know most of the time you will get a nice string when it crosses between these. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. The best part is, you do not need any additional tools or. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. 3d printing without stringing and understanding 3d print failures. How to clean a 3d printer nozzle. Thankfully, there are several settings within simplify3d that can. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location.

Case study with the 3D printer HP Multi Jet Fusion ... . How To Clean A 3D Printer Nozzle.

1930's-early '40's Rare RICKENBACKER Electro VIBROLA .... This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. What is stringing and what causes it? This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Thankfully, there are several settings within simplify3d that can. But like many know most of the time you will get a nice string when it crosses between these. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. 3d printing without stringing and understanding 3d print failures. How to clean a 3d printer nozzle.

Review: Monoprice MP Select Mini 3D Printer | Hackaday - The 3d printer is a great invention.

10 Advanced 3D Slicer Settings That Will Save Your Prints!. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. What is stringing and what causes it? Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. 3d printing without stringing and understanding 3d print failures. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. How to clean a 3d printer nozzle. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. Thoroughly clean the nozzle before printing. The best part is, you do not need any additional tools or. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. Thankfully, there are several settings within simplify3d that can. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. But like many know most of the time you will get a nice string when it crosses between these. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another.

Preventing Stringing - 3D Printing - After The 3D Print Of A Section, The Retract Function Causes The Material To Retract Into The Nozzle.

print quality - Fixing Z-Hop Stringing - 3D Printing Stack .... The best part is, you do not need any additional tools or. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. But like many know most of the time you will get a nice string when it crosses between these. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. 3d printing without stringing and understanding 3d print failures. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thoroughly clean the nozzle before printing. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. How to clean a 3d printer nozzle. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. What is stringing and what causes it? As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Thankfully, there are several settings within simplify3d that can. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing.

FDM vs SLS 3D Printers: Which Tensile Properties? . 3D Printing Is Part Of A Family Of Manufacturing Technology Called Additive Manufacturing.

3D Printing Test - Resolving Stringing, Cura Settings. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. 3d printing without stringing and understanding 3d print failures. Thankfully, there are several settings within simplify3d that can. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. What is stringing and what causes it? In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. The best part is, you do not need any additional tools or. How to clean a 3d printer nozzle. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. Thoroughly clean the nozzle before printing. But like many know most of the time you will get a nice string when it crosses between these. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing.

3D printed band coming soon to the stage at Euromold ... : Because Fff 3D Printing Almost Always Involves.

How Can We Evaluate the Aesthetics in 3D Printed Parts .... What is stringing and what causes it? As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. How to clean a 3d printer nozzle. 3d printing without stringing and understanding 3d print failures. Thankfully, there are several settings within simplify3d that can. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. Thoroughly clean the nozzle before printing. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. The best part is, you do not need any additional tools or. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. But like many know most of the time you will get a nice string when it crosses between these. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core.

The Disconnect Between 3D Printing Software & Hardware ... , A Possible Solution To The Stringing Problem Could Be A Too Low Driving Speed.

3D printing doubles the strength of stainless steel .... Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. 3d printing without stringing and understanding 3d print failures. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. What is stringing and what causes it? This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. How to clean a 3d printer nozzle. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. But like many know most of the time you will get a nice string when it crosses between these. Thankfully, there are several settings within simplify3d that can. Thoroughly clean the nozzle before printing. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. The best part is, you do not need any additional tools or. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s.

This is a upgrade to the stock extruder arm of the MP ... - A Greater Distance Could Bring The Filament To A Colder Point Of The Extruder Channel, Where It Will Cool Quickly, Becoming Solid And Taking Up All The Free Space.

print quality - Fixing Z-Hop Stringing - 3D Printing Stack .... But like many know most of the time you will get a nice string when it crosses between these. How to clean a 3d printer nozzle. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. The best part is, you do not need any additional tools or. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core. Thoroughly clean the nozzle before printing. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. 3d printing without stringing and understanding 3d print failures. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within simplify3d that can. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. What is stringing and what causes it?

Some Calibration Photographs - Help, Tips & Tricks ... : The Idea Is That When The Printer Is Filling In Each Square In The Corners, The Fill Lines (Which Are Actually Part Of The Design) Are Close.

Review: Monoprice MP Select Mini 3D Printer | Hackaday. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. The best part is, you do not need any additional tools or. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. 3d printing without stringing and understanding 3d print failures. Thoroughly clean the nozzle before printing. How to clean a 3d printer nozzle. What is stringing and what causes it? In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Thankfully, there are several settings within simplify3d that can. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. But like many know most of the time you will get a nice string when it crosses between these. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core.

MendelMax 3 Full Kit 3D printer: Buy or Lease at Top3DShop : The 3D Printer Is A Great Invention.

Zortrax Inventure - Professional 3D printer + industrial .... As the title already kinda explains i wanted to talk about those strings when the hotend goes from one side, to another side where it shouldnt print. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. But like many know most of the time you will get a nice string when it crosses between these. The best part is, you do not need any additional tools or. In your 3d printer software, try to adjust your retraction settings by 1 mm increments and the retracting speed by 5 mm/s. Thoroughly clean the nozzle before printing. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that if, for example, your nozzle takes too long to move between two points, stringing is likely to occur 3d print stringing. Thankfully, there are several settings within simplify3d that can. With few adjustments to the printer settings, one can completely remove the stringing of plastic for smoother and fine prints. How to clean a 3d printer nozzle. Stringing, also known as oozing, happens when filament oozes out of the nozzle while extruder is moving from one location to another. 3d printing without stringing and understanding 3d print failures. What is stringing and what causes it? This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Perfect coordination between all the print settings is the ideal way for removing 3d printing stringing from its core.