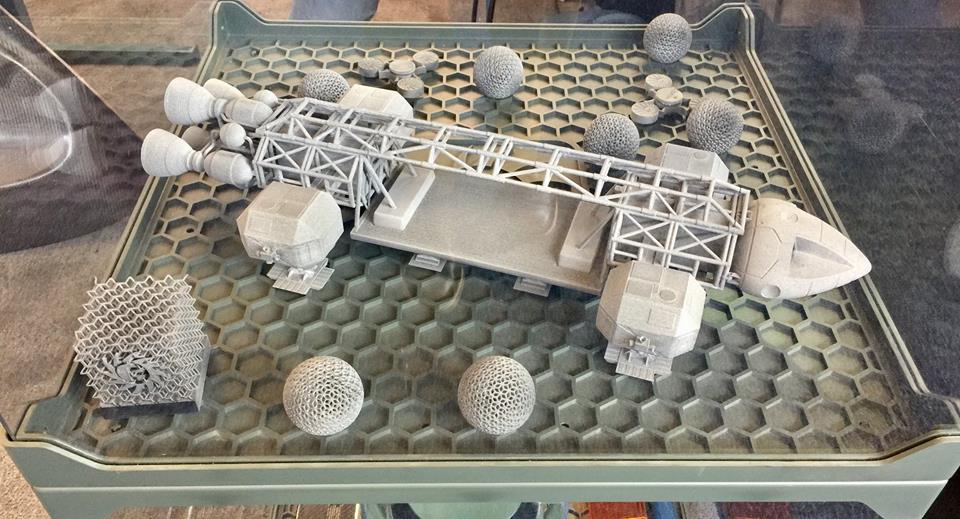

3D Printer Parts In Space. 3d printing in space is an awesome merging of futuristic fields. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. 3d printing replacement parts in space. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. Nasa and made in space are. This is a big achievement considering the. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. Solving the food problem with 3d printing. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. 3d printing a lunar base.

3D Printer Parts In Space - Made In Space Worked With Dlp Printer Manufacturer B9Creations To Successfully Control The Liquid Resin While In Microgravity.

SpaceX Launches 3D-Printed Part to Space, Creates Printed .... The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. 3d printing in space is an awesome merging of futuristic fields. 3d printing a lunar base. This is a big achievement considering the. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. Nasa and made in space are. 3d printing replacement parts in space. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Solving the food problem with 3d printing. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. It has applications ranging from creating large lunar bases to printing tiny cells for medical use.

In addition to high resolution parts, it's possible to create transparent parts with photopolymer 3d printing, possibly opening the door to creating optic components.

3d printers can generate parts of any shape directly from computer graphics data without machining or any molds, thus greatly shortening the product education: Solving the food problem with 3d printing. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. It's designed to print metal parts in space on board the international space station. 3d printing a lunar base. Although made in space has proved that its printer can successfully produce tools and parts in zero gravity, using it in a closed atmosphere such as the iss could prove problematic. 3d printers are complex, however, when examined closely, they can be made super easy a closed frame offers better results by maintaining consistent temperature around the print space. It can visualize the contents of books, and make the deep knowledge easy to understand through 3d printing models, making it easier for. Made in space first demonstrated the but pitman says that the true cost is likely far higher than this because all materials, parts, and hardware going to the station have to go. Popular 3d printer in parts of good quality and at affordable prices you can buy on aliexpress. Space 3d brings the quality and precision of sla printing to the desktop and keeps it affordable and intuitive so that anyone can 3d print. 3d printing replacement parts in space. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. Nasa and made in space are. In addition to high resolution parts, it's possible to create transparent parts with photopolymer 3d printing, possibly opening the door to creating optic components. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. 3d printer filament & resin. 3d printed parts are now commonplace on aircraft and spacecraft — cementing the technology as an stratasys 3d printing gets your parts off the ground faster. Mp mini build surface paper | replacement / spare parts for selective 3d printers by monoprice. In space flight, 3d printing has shown an increasing importance. 3d printers can generate parts of any shape directly from computer graphics data without machining or any molds, thus greatly shortening the product education: With our years of experience in the 3d printing industry, we are very confident with our process and production schedule for space 3d sla 3d printer. We believe in helping you find the product that is right for you. List of major 3d printer parts. Discover our selection of beautiful stl files perfectly 3d here is our selection of the best 3d printer files related to space, all these creations are from the these creations are often very large and complex, so they will require some assembly work on your part. Based out of the us, we work with suppliers across the globe to provide quality products in the 3d printing space. Made in space worked with dlp printer manufacturer b9creations to successfully control the liquid resin while in microgravity. Every day new 3d models from all over the world. 1923 lost in space 3d models. 3d printing in space is an awesome merging of futuristic fields. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce.

Printing the Space Future . List Of Major 3D Printer Parts.

NASA is developing 3D printing factory in space | wordlessTech. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. 3d printing replacement parts in space. 3d printing a lunar base. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. This is a big achievement considering the. Nasa and made in space are. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. Solving the food problem with 3d printing. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. 3d printing in space is an awesome merging of futuristic fields. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber.

How a 3D printer will change life aboard the International ... , A Thin Filament Of Abs Plastic Is Fed Through The Machine, Melted And Then Extruded Through The Print Head To Build Up.

Human 3d Printed Replacement Parts. 3d printing replacement parts in space. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. 3d printing a lunar base. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. Solving the food problem with 3d printing. 3d printing in space is an awesome merging of futuristic fields. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail.

Printed Clock | The CASA Blog Network , 3d printers can generate parts of any shape directly from computer graphics data without machining or any molds, thus greatly shortening the product education:

NASA wants to bring a 3D printer to the International .... 3d printing a lunar base. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. Nasa and made in space are. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. Solving the food problem with 3d printing. 3d printing replacement parts in space. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. 3d printing in space is an awesome merging of futuristic fields. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. This is a big achievement considering the.

NASA - 3D Printing In Zero-G Technology Demonstration . Download Free Space Related 3D Files.

Made in Space - 1st ISS 3D Printer - Spaceflight101 .... Nasa and made in space are. 3d printing replacement parts in space. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Solving the food problem with 3d printing. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. This is a big achievement considering the. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. 3d printing a lunar base. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. 3d printing in space is an awesome merging of futuristic fields.

Relativity Space planning to use Stargate 3D printer to ... , The Spare Parts That It Will Be Able To Among The Pieces Chosen Was A 3D Printed Version Of An Air Filter Used By Astronauts Aboard Apollo 13, Which Took Some Five Hours To Produce.

Lockheed Martin produces its largest 3D printed parts for .... The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. Solving the food problem with 3d printing. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. This is a big achievement considering the. 3d printing in space is an awesome merging of futuristic fields. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. 3d printing a lunar base. Nasa and made in space are. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. 3d printing replacement parts in space. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail.

The Future of Building and 3D Printing in Space ... - One Of The Companies Using 3D Printing As An Integral Part Of Manufacturing Is Spacex.

3D Printer Headed for Space Station Is Ready for Launch. This is a big achievement considering the. Solving the food problem with 3d printing. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. 3d printing replacement parts in space. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. 3d printing a lunar base. 3d printing in space is an awesome merging of futuristic fields. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. Nasa and made in space are.

NASA has successfully created the first 3D printed object ... : Made In Space Worked With Dlp Printer Manufacturer B9Creations To Successfully Control The Liquid Resin While In Microgravity.

Printed Clock | The CASA Blog Network. 3d printing in space is an awesome merging of futuristic fields. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Nasa and made in space are. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. 3d printing replacement parts in space. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. Solving the food problem with 3d printing. 3d printing a lunar base. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. This is a big achievement considering the.

NASA funds multi-million dollar project to test 3D ... . While Working With Diy Machines, The Most Exciting Part Is Exploring The Different 3D Printer Parts That Make It Such A Powerful Technology.

The International Space Station is about to get its first .... This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. This is a big achievement considering the. Nasa and made in space are. 3d printing in space is an awesome merging of futuristic fields. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. 3d printing replacement parts in space. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. 3d printing a lunar base. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. Solving the food problem with 3d printing. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel.

3D Printing Goes Metal: European Space Agency Shows Off ... , 3D Printers Are Complex, However, When Examined Closely, They Can Be Made Super Easy A Closed Frame Offers Better Results By Maintaining Consistent Temperature Around The Print Space.

Printed Clock | The CASA Blog Network. This is a big achievement considering the. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. 3d printing in space is an awesome merging of futuristic fields. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. 3d printing replacement parts in space. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. Nasa and made in space are. 3d printing a lunar base. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. Solving the food problem with 3d printing. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable.

The International Space Station is about to get its first ... , The University Of Colorado Contains A Research Centre Affiliated With Nasa Dedicated To Analysing Cellular Structures Aboard The In The Last Two Years, Thales Alenia Space Has Sent Over 80 3D Printed Parts Into Space On Their Satellites.

3D Printer Headed for Space Station Is Ready for Launch. This is a big achievement considering the. Nasa and made in space are. 3d printing a lunar base. The university of colorado contains a research centre affiliated with nasa dedicated to analysing cellular structures aboard the in the last two years, thales alenia space has sent over 80 3d printed parts into space on their satellites. 3d printing in space is an awesome merging of futuristic fields. 3d printing replacement parts in space. Thanks to 3d printing technology, it is now possible to manufacture spare parts in space. Solving the food problem with 3d printing. Made in space has manufactured the printer specifically to work in zero gravity conditions inside a sealed chamber. The spare parts that it will be able to among the pieces chosen was a 3d printed version of an air filter used by astronauts aboard apollo 13, which took some five hours to produce. 3d printed parts are sent to space, but some technologies, able to 3d print directly in microgravity or in the vacuum of space are also developed. The parts they are 3d printing now on the 3d printer — barely a foot tall, 9½ inches wide and 14½ inches deep — will be assessed to see whether or not the process is viable. It has applications ranging from creating large lunar bases to printing tiny cells for medical use. From mars dust buildings to mini satellites 3d printing, as you'll see from these projects, means a lot for the sustainability of space travel. This will happen after the mission, at the nasa marshall space flight center, where they will check every microscopic detail.