3D Printer In Space Station. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. 3d printing in space is an awesome merging of futuristic fields. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. This 3d printer uses the fused deposition modeling. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. A new breed of plastic. The technology demonstration will print objects in the space station's microgravity science glovebox. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. In space flight, 3d printing has shown an increasing importance. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in.

3D Printer In Space Station . This Is The Subject Of Research By.

Plastic Recycler Will Turn Space Station Trash into 3D .... When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. 3d printing in space is an awesome merging of futuristic fields. A new breed of plastic. This 3d printer uses the fused deposition modeling. In space flight, 3d printing has shown an increasing importance. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The technology demonstration will print objects in the space station's microgravity science glovebox. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that.

Users on earth can pay to use amf, a 3d printer specially designed to operate in a microgravity environment, to print products on the space station.

This 3d printer uses the fused deposition modeling. In space flight, 3d printing has shown an increasing importance. Once the printer makes its way to the iss, it will be immediately installed in the microgravity science glovebox (msg) on the station. 19 aboard spacex's unmanned dragon cargo capsule, could help. The faceplate, which bears the logos for made in space and. The issue isn't with the technical readiness of 3d printers for space station employment. A new breed of plastic. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. This could really open up the possibilities for companies, instead of only government. Regarding the additive technology outside of the station, it could also simplify logistics. The first 3d printer ever to fly in space will blast off this month, and nasa has high hopes for the innovative device's test runs on the international space station. A rendering of the axiom space station. When the cells arrived at the space station, cosmonauts fed them into a 3d printer, which produced thin steaks. Made in space's additive manufacturing facility / image courtesy of made in space. A 3d printer testbed was installed on the international space station this week. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. Nasa is all set to send the fourth spacex cargo mission, that would carry among other equipments a 3d printer to the international space station the dragon spacecraft will carry special purpose inexpensive satellite (spinsat) to test how a small satellite moves and positions itself in space using. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. Made in space plans to offer 3d printing from space to companies and individuals. The 3d printer, which is scheduled to launch toward the orbiting lab sept. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. This 3d printer uses the fused deposition modeling. 3d printing in space is an awesome merging of futuristic fields. But what about medical equipment? We're starting with plastic with this first printer, but we will be moving to metals and other. The object, a replacement faceplate for the printer's casing that holds its internal wiring in place, is one of about 20 objects that will be printed aboard international space station (iss). Cosmonaut oleg kononenko on board of the international space station during the first experiment with 3d bioprinter in december 2018. A space capsule carrying a 3d printer to make human tissue is on its way to the international space station after a thunderous spacex launch. Cosmonauts fed meat cells into a 3d printer. A 3d printer working in orbit would allow to create satellite.

International Space Station's 3D Printer Pops Out First ... . The Object, A Replacement Faceplate For The Printer's Casing That Holds Its Internal Wiring In Place, Is One Of About 20 Objects That Will Be Printed Aboard International Space Station (Iss).

ESA to Send 3D Printer to International Space Station .... The technology demonstration will print objects in the space station's microgravity science glovebox. 3d printing in space is an awesome merging of futuristic fields. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. In space flight, 3d printing has shown an increasing importance. A new breed of plastic. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. This 3d printer uses the fused deposition modeling. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration.

We did it! We 3D printed in space - Gigaom - Regarding The Additive Technology Outside Of The Station, It Could Also Simplify Logistics.

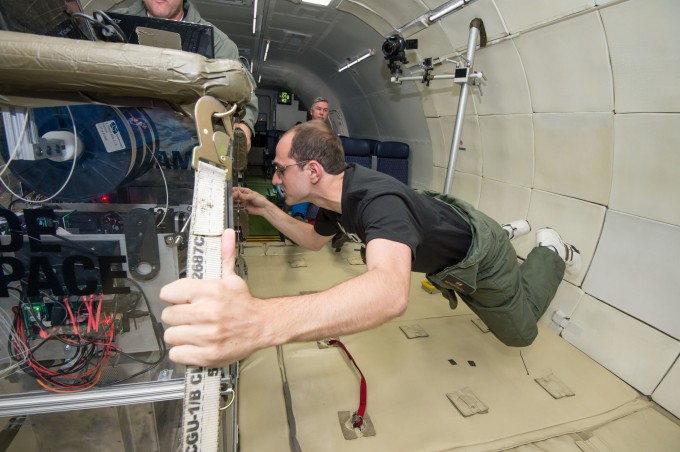

NASA - Marshall Star, March 20, 2013 Edition | NASA. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. This 3d printer uses the fused deposition modeling. In space flight, 3d printing has shown an increasing importance. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The technology demonstration will print objects in the space station's microgravity science glovebox. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a.

Printing Challenges For First 3D Printer Aboard ... . The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains.

3D Printer Boldly Heading to Space Station in 2014! - 3D .... The technology demonstration will print objects in the space station's microgravity science glovebox. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. 3d printing in space is an awesome merging of futuristic fields. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. This 3d printer uses the fused deposition modeling. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. In space flight, 3d printing has shown an increasing importance. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. A new breed of plastic. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration.

First Successful 3D Print In Space Completed - Make: | Make: , When A Tool On The Space Station Breaks Or Goes Missing These Days, Astronauts Must Often Wait For Months For The Next Supply Mission The 3D Printer Sent To The International Space Station (Iss) Will Be Able To Utilize A Variety Of Materials To Craft Items That The Astronauts Need, In A.

A BFF in Space! Bioprinter Will 3D-Print Human Tissue on .... The technology demonstration will print objects in the space station's microgravity science glovebox. 3d printing in space is an awesome merging of futuristic fields. A new breed of plastic. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. In space flight, 3d printing has shown an increasing importance. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. This 3d printer uses the fused deposition modeling. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that.

How 3D Printers Could Reinvent NASA Space Food | Space . Part Of The Challenge Of Designing A 3D Printer For The Station Was To Ensure Its Operation Does Not Affect The Crew Environment, Added Giorgio Musso Of Thales Alenia Space Italy, Principal Investigator For The.

NASA, Made in Space think big with Archinaut, a robotic 3D .... 3d printing in space is an awesome merging of futuristic fields. A new breed of plastic. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. This 3d printer uses the fused deposition modeling. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. In space flight, 3d printing has shown an increasing importance. The technology demonstration will print objects in the space station's microgravity science glovebox. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration.

The First Print in Space - 3D Printing Industry , Cosmonauts Fed Meat Cells Into A 3D Printer.

Astronaut Excited about 3D Printing on International Space .... The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The technology demonstration will print objects in the space station's microgravity science glovebox. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: This 3d printer uses the fused deposition modeling. In space flight, 3d printing has shown an increasing importance. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. A new breed of plastic. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. 3d printing in space is an awesome merging of futuristic fields. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in.

SpaceX Dragon Supply Ship Delivers Mice, 3D Printer to ... : The 3D Print Experiment Performed Well During Microgravity Flight Tests This Summer, But One Last Battery Of Tests Remains.

First 3D Printer Will Be Sent to Space By NASA Next Month .... This 3d printer uses the fused deposition modeling. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. The technology demonstration will print objects in the space station's microgravity science glovebox. 3d printing in space is an awesome merging of futuristic fields. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. A new breed of plastic. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: In space flight, 3d printing has shown an increasing importance. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a.

Iss-International-Space-Station-3d-model | RockThe3D : This 3D Printer Uses The Fused Deposition Modeling.

NASA - 3D Printing In Zero-G Technology Demonstration. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. 3d printing in space is an awesome merging of futuristic fields. The technology demonstration will print objects in the space station's microgravity science glovebox. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. A new breed of plastic. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. In space flight, 3d printing has shown an increasing importance. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. This 3d printer uses the fused deposition modeling. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station.

Impression 3D pour l'espace - applications et avantages : The Company Behind The Portal 3D Printer Is Made In Space—A Fitting Name For This Silicon Valley Team Comprised Of Entrepreneurs, Space Experts And Key 3D Printing Developers.

Europe's 3D printer set for Space Station / Space .... In space flight, 3d printing has shown an increasing importance. This 3d printer uses the fused deposition modeling. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. The technology demonstration will print objects in the space station's microgravity science glovebox. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. A new breed of plastic. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. 3d printing in space is an awesome merging of futuristic fields. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station.

Aerospace 3D Printing, Prototyping in Space - RevPart , Made In Space's Additive Manufacturing Facility / Image Courtesy Of Made In Space.

Gigaom | How a 3D printer will change life aboard the .... The 3d print experiment performed well during microgravity flight tests this summer, but one last battery of tests remains. The company behind the portal 3d printer is made in space—a fitting name for this silicon valley team comprised of entrepreneurs, space experts and key 3d printing developers. 3d printing in space is an awesome merging of futuristic fields. The object, a printhead faceplate, is engraved with names of the organizations that collaborated on this space station technology demonstration. The unique challenges of 3d printing in space include designing a printer that is sturdy enough to survive a rocket launch, reliable enough to work properly after that rocket launch, and safe and clean enough to use in. The technology demonstration will print objects in the space station's microgravity science glovebox. The space stations 3d printing program manager niki werkheiser explained, for the printer's final test in this phase of operations, nasa wanted made in space developed a new material that allows printed hardware to be used outside as well as inside the space station. A new breed of plastic. In 2014, nasa scientists aboard the international space station (iss) 3d printed a ratchet wrench using files transmitted from earth. 3d printing could revolutionize space exploration by helping astronauts to create objects in space and on demand: This 3d printer uses the fused deposition modeling. When a tool on the space station breaks or goes missing these days, astronauts must often wait for months for the next supply mission the 3d printer sent to the international space station (iss) will be able to utilize a variety of materials to craft items that the astronauts need, in a. The payload was developed to comply with all safety standards of the space station and completed an extensive testing campaign that. Replacement parts for repairs, custom they managed to create a ratchet wrench from a 3d file emailed from earth to the space station. In space flight, 3d printing has shown an increasing importance.