3D Printer Glass Warped. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. Everything has a tolerance to it, whether the manufacturer provided it or not. An open discussion on warping & shrinkage on our 3d printing work. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Yes, glass warps when hot. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. At 50 and 60 degree bed temps the part warps. Here are 10 easy ways to fix 3d print warping. This method can work on most of 3d printers. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly.

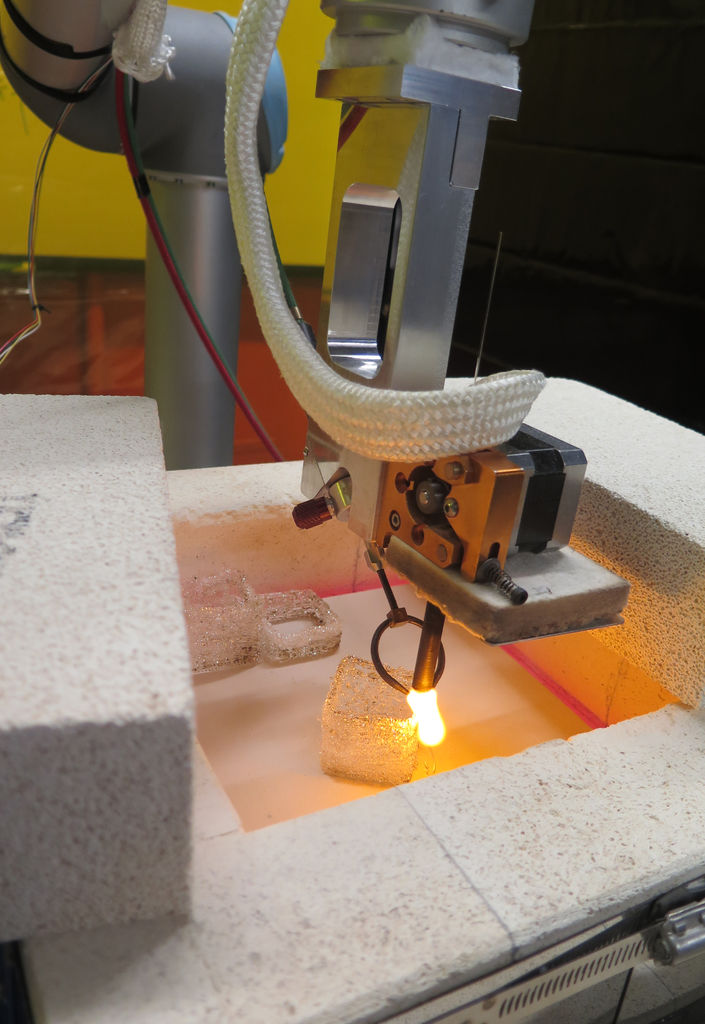

3D Printer Glass Warped , The G3Dp Process Produces An Array Of Quite Beautiful Glass Objects Worthy Of A Dale Chihuly Exhibit.

taulman3D Hacks Their Clear t-glase 3D Printing Material .... The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. An open discussion on warping & shrinkage on our 3d printing work. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Everything has a tolerance to it, whether the manufacturer provided it or not. At 50 and 60 degree bed temps the part warps. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Yes, glass warps when hot. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. Here are 10 easy ways to fix 3d print warping. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. This method can work on most of 3d printers. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer.

Lastly, repeated print and bed heat cycles can warp your aluminum.

After becoming very frustrated with abs plastic objects warping when the bottom corners would pull loose from the build platform, i started searching for a. In this guide, i'll explain reasons why you should print on a glass bed, whether or not your thus, you end up with an imperfect print with poor layer adhesion and quality. Warping over the first few layers but remained stuck to the cardboard throughout the print. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. At 50 and 60 degree bed temps the part warps. This printer integrated with a tempered glass bed, greatly resolving warped bed issues. If your printer uses a glass bed, you can also use pet sheets. Thingiverse is a universe of things. Yes, glass warps when hot. Because fff 3d printing almost always involves thermoplastics, this happens with almost every fff 3d printer. This is a more advanced system and is quite impressive. The 200% extrusion gave double thick, very strong walls. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. And while previous glass 3d printing methods have used powdered glass and silica sand, a team of researchers led by neri oxman out of mit's mediated matter / 3d printer extrudes molten gla. Warping is still a consistent issue that you need to account for, as well as the potentially dangerous before 3d printing with asa make sure your 3d printer meets the hardware requirements listed below to ensure the best print quality. The printer uses a dual heated chamber. It is strong enough the pad. Since glass and aluminum are smooth, your first layer doesn't have many nooks or crevices to flow into which means your models are more prone to sticking or warping issues (as. So, using silicone square soft conformal pads lets the glass float and not be impacted by warping forces of the aluminum. I was looking at getting a piece of glass cut to size, however, i have read you need to apply glue stick to the glass bed to get the pla to stick, but other sites don't mention using glue or anything. 3d printed parts warp because of thermal deformation. For all the years i have been using home 3d printers, one fundamental aspect is still causing frustration for new and experienced users alike. There are many different 3d printing materials, each with unique strengths and weaknesses. A wide variety of 3d printer warping options. And provides protection to your heated bed and easy to participating in a new and silly tradition of designating mildly upgraded 3d printers as pro, the longer lk4 pro is, unsurprisingly, an evolution of the lk4. Things tagged with '3d_printer_enclosure' (502 things). News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Glass printer bed 235x235x3.8mm borosilicate glass 3d printer glass print platforms for ender 5/ender 3/ender 3 pro. This printer is different in that the heater is an etched circuit attached to the aluminum plate. The upper chamber acts as a 1900°f kiln while the lower chamber serves to anneal the structures. Download files and build them with your 3d printer, laser cutter, or cnc.

Advanced Glass 3D Printer Developed by Mediated Matter and ... : This Printer Is Different In That The Heater Is An Etched Circuit Attached To The Aluminum Plate.

You Can Now 3D Print Glass | Innovation | Smithsonian Magazine. Here are 10 easy ways to fix 3d print warping. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. At 50 and 60 degree bed temps the part warps. This method can work on most of 3d printers. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Yes, glass warps when hot. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. An open discussion on warping & shrinkage on our 3d printing work. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Everything has a tolerance to it, whether the manufacturer provided it or not.

you can now 3D print in glass with Shapeways | 3d printing ... : Use A Physical Touch Sensor And Calibrate It Out, Or Swap Glass If It's Bad.

Micron3DP & MIT 3D printing in molten glass - 3D Printing .... I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Yes, glass warps when hot. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. This method can work on most of 3d printers. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Use a physical touch sensor and calibrate it out, or swap glass if it's bad.

3D Laser Engraving Machine & Crystal & Glass Laser ... , Hello everyone, we are looking at 3d print bed surfaces and coatings in this post.

MIT Made A 3D Printer That Uses Glass - YouTube. Yes, glass warps when hot. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Here are 10 easy ways to fix 3d print warping. Everything has a tolerance to it, whether the manufacturer provided it or not. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. This method can work on most of 3d printers. An open discussion on warping & shrinkage on our 3d printing work. At 50 and 60 degree bed temps the part warps.

3D printed transparent glass. a) Schematics of the ... . On The Printer Side, There Are Two Things That Fix Warping.

Glass Print Platform 4 FlashForge Creator PRO/Dreamer 3D .... Here are 10 easy ways to fix 3d print warping. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. This method can work on most of 3d printers. At 50 and 60 degree bed temps the part warps. An open discussion on warping & shrinkage on our 3d printing work. Yes, glass warps when hot. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. Everything has a tolerance to it, whether the manufacturer provided it or not. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat.

Say No to ABS Crack Warp during 3d printing , MingDa 3D ... : This Is A More Advanced System And Is Quite Impressive.

Glass Print Bed - For Under $1 - 3D Printer - YouTube. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. At 50 and 60 degree bed temps the part warps. Here are 10 easy ways to fix 3d print warping. This method can work on most of 3d printers. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. An open discussion on warping & shrinkage on our 3d printing work. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Yes, glass warps when hot. Everything has a tolerance to it, whether the manufacturer provided it or not. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly.

3D printing Glue Stick Non toxic anti warping for 3D ... : A Wide Variety Of 3D Printer Warping Options.

Warp Zone Live - Meet Edward Calderhead, 3D Printer and 3D .... The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. Here are 10 easy ways to fix 3d print warping. At 50 and 60 degree bed temps the part warps. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. An open discussion on warping & shrinkage on our 3d printing work. Everything has a tolerance to it, whether the manufacturer provided it or not. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. This method can work on most of 3d printers. Yes, glass warps when hot. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. I just installed a new glass bed (not used one before) and am having issues getting parts to stick.

3D printers can now print in glass | TechRadar - In This Guide, I'll Explain Reasons Why You Should Print On A Glass Bed, Whether Or Not Your Thus, You End Up With An Imperfect Print With Poor Layer Adhesion And Quality.

You Can Now 3D Print Glass | Innovation | Smithsonian Magazine. This method can work on most of 3d printers. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. At 50 and 60 degree bed temps the part warps. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. An open discussion on warping & shrinkage on our 3d printing work. Yes, glass warps when hot. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Here are 10 easy ways to fix 3d print warping. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. Everything has a tolerance to it, whether the manufacturer provided it or not.

Glass from a 3D printer | ETH Zurich : And While Previous Glass 3D Printing Methods Have Used Powdered Glass And Silica Sand, A Team Of Researchers Led By Neri Oxman Out Of Mit's Mediated Matter / 3D Printer Extrudes Molten Gla.

Neri Oxman 3D Prints Transparent Glass Into Sculptural .... Use a physical touch sensor and calibrate it out, or swap glass if it's bad. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. An open discussion on warping & shrinkage on our 3d printing work. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Everything has a tolerance to it, whether the manufacturer provided it or not. At 50 and 60 degree bed temps the part warps. Yes, glass warps when hot. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. This method can work on most of 3d printers. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. Here are 10 easy ways to fix 3d print warping. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth.

3D Printing Glass | Hackaday , How Does A 3D Printer Work?

Virginia Tech and the Rhode Island School of Design are 3D .... Yes, glass warps when hot. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Everything has a tolerance to it, whether the manufacturer provided it or not. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. At 50 and 60 degree bed temps the part warps. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. An open discussion on warping & shrinkage on our 3d printing work. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. Here are 10 easy ways to fix 3d print warping. This method can work on most of 3d printers.

Looking at 3D Printed Glass Designs - are You Mesmerized ... . On The Printer Side, There Are Two Things That Fix Warping.

Replicating Stained Glass with a 3D Printer - YouTube. At 50 and 60 degree bed temps the part warps. This method can work on most of 3d printers. Use a physical touch sensor and calibrate it out, or swap glass if it's bad. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. If pla, abs, or petg prints cool unevenly, they can curl on the build plate, creating a warped bottom layer. Here are 10 easy ways to fix 3d print warping. Today i'd like to talk to you about warping and how to minimize the effects that shrinkage can have using bare glass with glue stick using bare glass with aquanet using kapton tape with gluestick. A key aspect when working out how to prevent abs warping is getting your adhesion for the bed sorted perfectly. I just installed a new glass bed (not used one before) and am having issues getting parts to stick. Extruded thermoplastics have nothing to grab onto when they encounter smooth surfaces. Everything has a tolerance to it, whether the manufacturer provided it or not. Most printers come with a glass or aluminum build surface that is durable, but also far too smooth. An open discussion on warping & shrinkage on our 3d printing work. Yes, glass warps when hot. The further you go into mechanical studies like 3d printing, mills, and lathes, you will find out that nothing is perfectly flat.