3D Printed Joints Design. Fdm is good for low cost prototyping of interlocking. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. If you're designing a 3d printed object with moving parts, such as a. Print to build, joint collection. Learn how to design and 3d print interlocking joints (e.g. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. One of the most common kinds of joints for 3d printing is snap fits. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). 3d printing press fit parts. One of the possible solutions is the joint design. If we want to create larger objects with our printers, we should print only the small joints and we will be. These special connections work as follows: A design feature similar to a hook is. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations.

3D Printed Joints Design , Print To Build, 3D Printed Joint Collection.

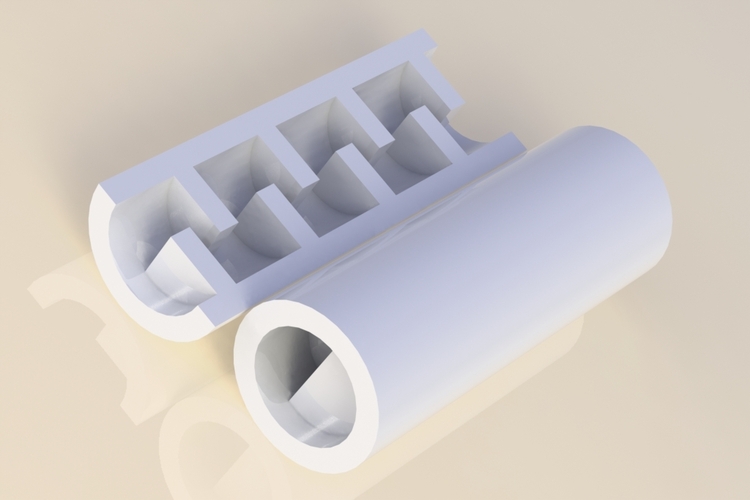

3D Printed Universal Joint - YouTube. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. One of the most common kinds of joints for 3d printing is snap fits. One of the possible solutions is the joint design. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Fdm is good for low cost prototyping of interlocking. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. A design feature similar to a hook is. Print to build, joint collection. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. If you're designing a 3d printed object with moving parts, such as a. Learn how to design and 3d print interlocking joints (e.g. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. 3d printing press fit parts. These special connections work as follows: If we want to create larger objects with our printers, we should print only the small joints and we will be.

In 3d printing, designing joints in your model is a great way to connect parts and allow movement.

In 3d printing, designing joints in your model is a great way to connect parts and allow movement. The other interface works like a linear ratchet with angled walls (to keep them from slipping apart) and teeth to set the. Moreover, the detailed design criteria and selection of suitable materials for different parts are elaborated. The 3d‐printing practice allows the plug also discussed are the configuration options of the plug to be surgically implanted in a joint. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. Download a file to print this set of plastic furniture joints on a desktop 3d printer and then pair them with plywood to create custom configurations. It is possible to build furniture, installations, partitions and anything else. Olle gellert 3d printed joints connect eight millimeter plywood sheets together in a variety of different angles, to help construct everyday furniture. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. Machine used for joint creation. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Although the focus of this paper is on the design, a brief. Tolerances for this type of joint can be especially challenging as too tight of we'll be using the graphic below which was designed in onshape to demonstrate some of the main parameters to keep in mind when creating. That is the next step that you are teaching. That way, you can adjust the fit of your joint without wasting filament printing out a whole part. Artificial joints have been traditionally made with a variety of plastics and metals, materials that are very clearly alien dr. Alex buckman presents the led design titled 'canopy'. I'm interested in 3d printing toy action figures, but what i don't quite know how the joints should be designed to allow flexibility. Upon design completion, we automatically engrave each joint with a visible i.d. Some printers may not print the thin wall between the back of the slot and. Design and construct your own furniture with 3d printed joints. Versatile, downloadable 3d printed joints for customized diy furniture. To design and construct large objects, ollé narrowed his research, developing and printing just the small. How do you adjust the tolerances and how do you do that in your cad. If we want to create larger objects with our printers, we should print only the small joints and we will be. Thus designing for 3d printing requires a new mindset, and part of that mindset is leveraging the geometric freedom of a 3d printer to reduce the rotating joint locking into place. Orthopedic implant makers like limacorporate can also customize the design of the final implant according to the patient's and surgeon's needs, keeping the same features of the original. See more ideas about plastic design, design, 3d printing. We then take that joint and use the patient's stem cells to. A clear advantage of the design is that it can easily be used.

Computational Design Student Creates 3D Printed Spider ... . The Connection Can Be 3D Printed And By Defining Sleeves For The Pipes You Can Insert Them In The Nodes.

Fastners for 3D Printing: Tenacity and robust pin joints .... In 3d printing, designing joints in your model is a great way to connect parts and allow movement. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. Learn how to design and 3d print interlocking joints (e.g. If you're designing a 3d printed object with moving parts, such as a. One of the most common kinds of joints for 3d printing is snap fits. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Print to build, joint collection. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. A design feature similar to a hook is. Fdm is good for low cost prototyping of interlocking. These special connections work as follows: 3d printing press fit parts. One of the possible solutions is the joint design. If we want to create larger objects with our printers, we should print only the small joints and we will be.

Sofa So Good is Finnish Janne Kyttanen's Latest 3D Printed ... : This Space Is Called Clearance.

plumb modular furniture features customizable connections. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). These special connections work as follows: 3d printing press fit parts. If you're designing a 3d printed object with moving parts, such as a. Print to build, joint collection. If we want to create larger objects with our printers, we should print only the small joints and we will be. A design feature similar to a hook is. One of the possible solutions is the joint design. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations.

Design of the Week: DIY Furniture Joints . A clear advantage of the design is that it can easily be used.

3D Printing CRB - Lishakilltech. Learn how to design and 3d print interlocking joints (e.g. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. A design feature similar to a hook is. One of the most common kinds of joints for 3d printing is snap fits. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. Print to build, joint collection. One of the possible solutions is the joint design. These special connections work as follows: Fdm is good for low cost prototyping of interlocking. 3d printing press fit parts. If you're designing a 3d printed object with moving parts, such as a. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. If we want to create larger objects with our printers, we should print only the small joints and we will be.

3D-Printed Furniture Joints : furniture joints , Be Very Careful At This Step;

Learn How to Add Ball Joints to Your 3D Printed Parts .... Fdm is good for low cost prototyping of interlocking. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. If we want to create larger objects with our printers, we should print only the small joints and we will be. One of the possible solutions is the joint design. 3d printing press fit parts. Learn how to design and 3d print interlocking joints (e.g. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. A design feature similar to a hook is. Print to build, joint collection. If you're designing a 3d printed object with moving parts, such as a. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. These special connections work as follows: One of the most common kinds of joints for 3d printing is snap fits.

How to connect two parts with 3D printed joints and snap fits . The First Step Is To Download The 3D Model, Which Was Designed By A Guy Named Alejandro Macias.

3D Printed Modular Ball-and-Socket Joints - 日本語. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). One of the most common kinds of joints for 3d printing is snap fits. If we want to create larger objects with our printers, we should print only the small joints and we will be. Fdm is good for low cost prototyping of interlocking. One of the possible solutions is the joint design. These special connections work as follows: The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. A design feature similar to a hook is. Print to build, joint collection. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. If you're designing a 3d printed object with moving parts, such as a. 3d printing press fit parts. Learn how to design and 3d print interlocking joints (e.g. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations.

3D Printed Universal Joint - YouTube - A Clear Advantage Of The Design Is That It Can Easily Be Used.

Mechanical Design for 3D Printing - The Adventures of Eiki .... 3d printing press fit parts. If you're designing a 3d printed object with moving parts, such as a. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Print to build, joint collection. One of the most common kinds of joints for 3d printing is snap fits. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. A design feature similar to a hook is. Learn how to design and 3d print interlocking joints (e.g. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. One of the possible solutions is the joint design. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. If we want to create larger objects with our printers, we should print only the small joints and we will be. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. Fdm is good for low cost prototyping of interlocking. These special connections work as follows:

Design of the Week: DIY Furniture Joints - Conversion Into The Stl Format Used By Most Originality/Value This Paper Proposes A New Design For The Journal In 3D Printed Revolute Joints.

3d printed ball joint - YouTube. These special connections work as follows: A design feature similar to a hook is. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Learn how to design and 3d print interlocking joints (e.g. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. One of the possible solutions is the joint design. Fdm is good for low cost prototyping of interlocking. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. If we want to create larger objects with our printers, we should print only the small joints and we will be. 3d printing press fit parts. One of the most common kinds of joints for 3d printing is snap fits. If you're designing a 3d printed object with moving parts, such as a. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. Print to build, joint collection.

Hybrid Joinery - Shiran Magriso & Amit Zoran. Wood ... - They Have To Make The 3D Digital Design Joints Fit In Plastics As You Are Printing Them.

It's a Snap - 4 Furniture Designs with 3D Printed .... Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Print to build, joint collection. 3d printing press fit parts. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. These special connections work as follows: In 3d printing, designing joints in your model is a great way to connect parts and allow movement. One of the most common kinds of joints for 3d printing is snap fits. A design feature similar to a hook is. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. Fdm is good for low cost prototyping of interlocking. If you're designing a 3d printed object with moving parts, such as a. One of the possible solutions is the joint design. If we want to create larger objects with our printers, we should print only the small joints and we will be. Learn how to design and 3d print interlocking joints (e.g.

3D Printed Joint Filter by steven_dakh | Pinshape . 3D Printed Joints Are All The Design Features You Can Insert In Your 3D Model To Connect Parts Together Without Using External Components (Not Even Glue).

How to connect two parts with 3D printed joints and snap fits. Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. A design feature similar to a hook is. Print to build, joint collection. 3d printing press fit parts. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. If we want to create larger objects with our printers, we should print only the small joints and we will be. If you're designing a 3d printed object with moving parts, such as a. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). One of the possible solutions is the joint design. These special connections work as follows: Learn how to design and 3d print interlocking joints (e.g. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Fdm is good for low cost prototyping of interlocking. One of the most common kinds of joints for 3d printing is snap fits.

Learn How to Add Ball Joints to Your 3D Printed Parts ... - The Connection Can Be 3D Printed And By Defining Sleeves For The Pipes You Can Insert Them In The Nodes.

Creating Articulated Figures with the 3Doodled Joint .... Sls and material jetting are best suited for interlocking joints due to their high print accuracy and material strength. Fdm is good for low cost prototyping of interlocking. In 3d printing, designing joints in your model is a great way to connect parts and allow movement. One of the possible solutions is the joint design. These special connections work as follows: 3d printing press fit parts. This all happens without the use of glue or screws, making your design 3d printed joints come in handy in all sorts of situations. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). A design feature similar to a hook is. If you're designing a 3d printed object with moving parts, such as a. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. If we want to create larger objects with our printers, we should print only the small joints and we will be. One of the most common kinds of joints for 3d printing is snap fits. Learn how to design and 3d print interlocking joints (e.g. Print to build, joint collection.