3D Printed Joint Ideas. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. But it isn't actually that hard. See more ideas about 3d printing, wood joints, wood joinery. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Simply put, a joint is any structure that joins two pieces together. 3d printed joints may seem intimidating, but they don't need to be hard. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. These special connections work as follows. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. One of the most common kinds of joints for 3d printing is snap fits. Learn how to 3d print joints with this simple guide! In 3d printing, designing joints in your model is a great way to connect parts and allow.

3D Printed Joint Ideas , A Sample Bookcase Built From The 3D Printed Joints.

Design of the Week: DIY Furniture Joints. 3d printed joints may seem intimidating, but they don't need to be hard. Learn how to 3d print joints with this simple guide! 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). See more ideas about 3d printing, wood joints, wood joinery. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. In 3d printing, designing joints in your model is a great way to connect parts and allow. But it isn't actually that hard. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. One of the most common kinds of joints for 3d printing is snap fits. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. These special connections work as follows. Simply put, a joint is any structure that joins two pieces together. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid.

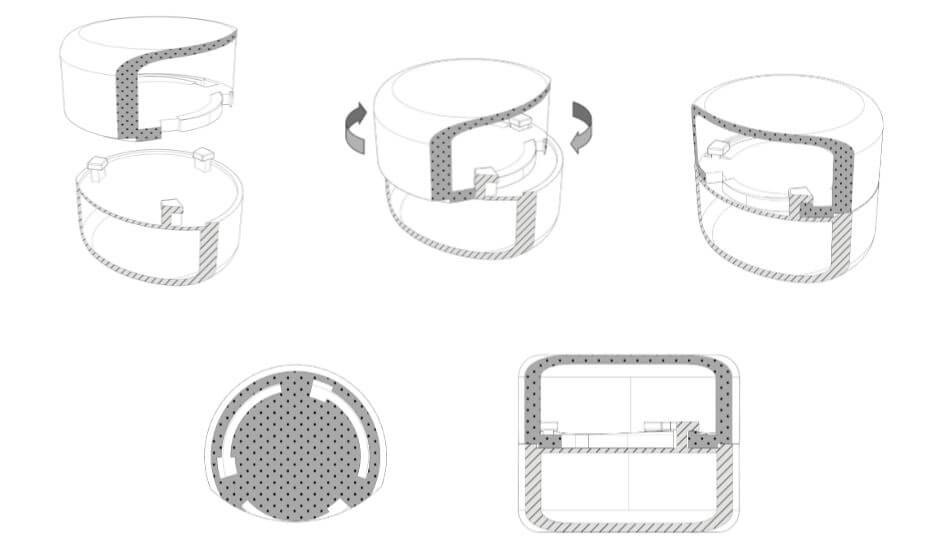

Learn how to design and 3d print custom snap fit enclosures.

The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. It is quite simple, and just involves some quick hands. The thing about this is, they are covered by the licensing involved with patterns found on thingiverse. Learn how to 3d print joints with this simple guide! Print to build, 3d printed joint collection. Versatile, downloadable 3d printed joints for customized diy furniture. As with anything printed or mechanical, it will wear over time. A zapciu et al 2018 iop conf. These 3d printable joints allow people to build their own furniture without the use of tools, fasteners or glue. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. Ball and socket joints are a powerful way of adding mobility and functionality to your 3d designs. A sample bookcase built from the 3d printed joints. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. 3d printing is implemented in a large number of industries, having an important role in reducing the. If you can print in 2d, can you print in 3d? Streamlined 3d printed prosthetic hand: By printing it first, you'll be able to take it with you when you head out to buy materials, and make sure that all the dowels and screws you get will fit properly. Love it, bought it and printing it :) alejandro marquez carrillo 2 года назад. Olle gellert 3d printed joints connect eight millimeter plywood sheets together in a variety of different angles, to help construct everyday furniture. Joint kit lets you build your own furniture. See more ideas about 3d printer, 3d printing, 3d printed furniture. To design and construct large objects, ollé narrowed his. One of the most common kinds of joints for 3d printing is snap fits. For a better idea of how to place the foam and velcro straps, refer to the spock basketball prosthetic. Once that's done, you're ready to print — but for best results, you should take a moment to ensure the printer's settings dialed in properly first. Learn how to design and 3d print custom snap fit enclosures. These special connections work as follows. We then take that joint. Captain phasma is leading a wave of attack on the resistance!the resistance is no piece of cake!

How to connect two parts with 3D printed joints and snap fits . It Is Quite Simple, And Just Involves Some Quick Hands.

3D-Printable Connectors Make DIY Furniture Assembly Easy .... But it isn't actually that hard. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). These special connections work as follows. Simply put, a joint is any structure that joins two pieces together. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Learn how to 3d print joints with this simple guide! Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. See more ideas about 3d printing, wood joints, wood joinery. One of the most common kinds of joints for 3d printing is snap fits. In 3d printing, designing joints in your model is a great way to connect parts and allow. 3d printed joints may seem intimidating, but they don't need to be hard. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled.

Alex Czech's 3D Printable Exoskeleton Hands are Now ... - These 3D Printable Joints Allow People To Build Their Own Furniture Without The Use Of Tools, Fasteners Or Glue.

Computational Design Student Creates 3D Printed Spider .... Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. But it isn't actually that hard. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. In 3d printing, designing joints in your model is a great way to connect parts and allow. Simply put, a joint is any structure that joins two pieces together. These special connections work as follows. Learn how to 3d print joints with this simple guide! The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. One of the most common kinds of joints for 3d printing is snap fits.

Print To Build, 3D printed joint collection on Behance , Wider access to the technology gives luxury shoppers and manufacturers.

3D Printed Joints - The Basics | All3DP. See more ideas about 3d printing, wood joints, wood joinery. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. But it isn't actually that hard. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. Learn how to 3d print joints with this simple guide! This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. 3d printed joints may seem intimidating, but they don't need to be hard. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). In 3d printing, designing joints in your model is a great way to connect parts and allow. These special connections work as follows. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. Simply put, a joint is any structure that joins two pieces together. One of the most common kinds of joints for 3d printing is snap fits.

Hybrid Joinery - Shiran Magriso & Amit Zoran. Wood ... , 3D Printed Stormtrooper Action Figure!

The 'Print to Build' 3D Printed Joint Collection Explores .... Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. 3d printed joints may seem intimidating, but they don't need to be hard. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. Simply put, a joint is any structure that joins two pieces together. One of the most common kinds of joints for 3d printing is snap fits. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. But it isn't actually that hard. These special connections work as follows. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. Learn how to 3d print joints with this simple guide! See more ideas about 3d printing, wood joints, wood joinery. In 3d printing, designing joints in your model is a great way to connect parts and allow. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue).

Shapeways Blog - How to Design Snap-Fit Ball Joints for 3D ... - This Is A Way That Will Amuse People (Similarly To The Boat In A Jar).

Easy Geodesic Domes Using 3D Printing. See more ideas about 3d printing, wood joints, wood joinery. But it isn't actually that hard. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. These special connections work as follows. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. 3d printed joints may seem intimidating, but they don't need to be hard. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. Simply put, a joint is any structure that joins two pieces together. Learn how to 3d print joints with this simple guide! One of the most common kinds of joints for 3d printing is snap fits. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. In 3d printing, designing joints in your model is a great way to connect parts and allow.

3D Printing CRB - Lishakilltech : Toyserkani Uses 3D Printing To Literally Construct The Joint Using Biodegradable Material.

3D printed Ball and Socket - YouTube. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. Learn how to 3d print joints with this simple guide! But it isn't actually that hard. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. One of the most common kinds of joints for 3d printing is snap fits. Simply put, a joint is any structure that joins two pieces together. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. 3d printed joints may seem intimidating, but they don't need to be hard. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). These special connections work as follows. In 3d printing, designing joints in your model is a great way to connect parts and allow. See more ideas about 3d printing, wood joints, wood joinery. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled.

3D Digital Design Joints : Toyserkani Uses 3D Printing To Literally Construct The Joint Using Biodegradable Material.

Ball-Joint Articulated Octopus Keyring Remix image .... But it isn't actually that hard. One of the most common kinds of joints for 3d printing is snap fits. Simply put, a joint is any structure that joins two pieces together. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. 3d printed joints may seem intimidating, but they don't need to be hard. In 3d printing, designing joints in your model is a great way to connect parts and allow. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. See more ideas about 3d printing, wood joints, wood joinery. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Learn how to 3d print joints with this simple guide! The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. These special connections work as follows. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled.

3D Printed Universal Joint - YouTube : See More Ideas About 3D Printing, Wood Joints, Wood Joinery.

How to connect two parts with 3D printed joints and snap fits. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. But it isn't actually that hard. One of the most common kinds of joints for 3d printing is snap fits. In 3d printing, designing joints in your model is a great way to connect parts and allow. 3d printed joints may seem intimidating, but they don't need to be hard. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. These special connections work as follows. Simply put, a joint is any structure that joins two pieces together. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). Learn how to 3d print joints with this simple guide! The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. See more ideas about 3d printing, wood joints, wood joinery.

3D Printed Joints Hold Great Promise for Patients Needing ... . Interlocking Joints Are A Common Method For Connecting Components That Are Regularly Assembled And Disassembled.

3D Printed Joints Hold Great Promise for Patients Needing .... Learn how to 3d print joints with this simple guide! One of the most common kinds of joints for 3d printing is snap fits. 3d printed joints may seem intimidating, but they don't need to be hard. Simply put, a joint is any structure that joins two pieces together. In 3d printing, designing joints in your model is a great way to connect parts and allow. The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge. See more ideas about 3d printing, wood joints, wood joinery. These special connections work as follows. But it isn't actually that hard. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue).

3D Printing Joints - Olle Gellert 3D Printed Joints Connect Eight Millimeter Plywood Sheets Together In A Variety Of Different Angles, To Help Construct Everyday Furniture.

Print To Build, 3D printed joint collection on Behance. 3d printed joints may seem intimidating, but they don't need to be hard. This is a very current problem, because in the past the main focus was on rapid prototyping but in the future it is on rapid. Interlocking joints are a common method for connecting components that are regularly assembled and disassembled. In 3d printing, designing joints in your model is a great way to connect parts and allow. Learn how to 3d print joints with this simple guide! The use of interlocking joints allows the table below provides a quick overview of the most common 3d printing technologies and whether they are appropriate for printing interlocking. Joints form the backbone of any complex structure, so designing 3d printing these joints might seem a bit daunting. See more ideas about 3d printing, wood joints, wood joinery. Simply put, a joint is any structure that joins two pieces together. But it isn't actually that hard. These special connections work as follows. 3d printed joints are all the design features you can insert in your 3d model to connect parts together without using external components (not even glue). The basic question driving my project is how we can make use desktop 3d printers as best as we can in our homes. One of the most common kinds of joints for 3d printing is snap fits. Interlocking joints are the least complicated, completely relying on friction between the parts to stay assembled, something like a da vinci bridge.