3D Printed Gears Strength. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Just be sure to design all your gears using the same tool to. The strength of 3d prints remelted in salt. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! While there are other alternative materials out there, we have you printed any gears yourself? Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. • 1,7 млн просмотров 3 года назад. In terms of thickness, it is recommended to design it at least. What advantages do 3d printer gears have? Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Nylon has the lubricity, strength, and flexibility required to make a. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla.

3D Printed Gears Strength . I Bought A Regular Nylon Gear And Installed That.

3D Printed Gear Serves Seven Months Hard Labor | Prints. What advantages do 3d printer gears have? The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. While there are other alternative materials out there, we have you printed any gears yourself? Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. In terms of thickness, it is recommended to design it at least. The strength of 3d prints remelted in salt. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Nylon has the lubricity, strength, and flexibility required to make a. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. Just be sure to design all your gears using the same tool to. • 1,7 млн просмотров 3 года назад. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication.

Indeed, 3d printed weapons are beyond any control.

The strength of 3d prints remelted in salt. While there are other alternative materials out there, we have you printed any gears yourself? What advantages do 3d printer gears have? Even cheap ink jet printers print very scale accurate but not all laser printers are accurate. Learn more about 3d printing guns. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Just be sure to design all your gears using the same tool to ensure that they mesh as intended. But if you are using fdm 3d printed gears anyway, then good enough is good enough. Could you give me an example brand? When possible, consider adding a backing to. Every day new 3d models from all over the world. Where to get things printed. I am unfamiliar with high strength pla. Just be sure to design all your gears using the same tool to. Hence, a person could potentially easily turn into a new kind of gun manufacturer with only a desktop 3d printer. It should give me years of service. The strength of 3d prints remelted in salt. Gordon used casts of his clients arm to ensure a comfortable fit. After printing, the model is sintered in a furnace. How is this material made? Indeed, 3d printed weapons are beyond any control. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish Strength cartel future long sleeve tee. Strength cartel family over fame tee. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. 2020 popular 1 trends in home improvement, men's clothing, toys & hobbies, computer & office with 3d print gear and 1. Improving issues in terms of both mechanical strength and. I recommend printing the gears with an ink jet printer. It is possible to print gears, but the teeth need to be quite large (and tolerances will be poor). This function hides the text at the bottom of this page and tells your browser to start the print dialog to print this page.

Anycubic Kossel 3D Printer Desktop DIY Auto-leveling Kit ... , Where To Get Things Printed.

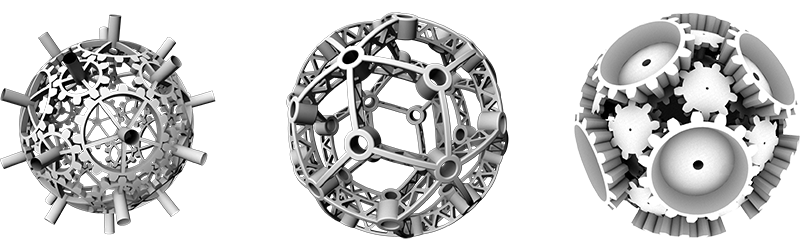

Discover technologies and applications for Metal 3D printing. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. The strength of 3d prints remelted in salt. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. In terms of thickness, it is recommended to design it at least. While there are other alternative materials out there, we have you printed any gears yourself? Nylon has the lubricity, strength, and flexibility required to make a. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! • 1,7 млн просмотров 3 года назад. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. What advantages do 3d printer gears have? The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Just be sure to design all your gears using the same tool to.

PLA vs. ABS: The Strength of 3D Printed Objects - 3D ... , The Formula Student Team From Weingarten Near.

SLA/3D printing ABS like material gear box for mechanical .... The strength of 3d prints remelted in salt. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. • 1,7 млн просмотров 3 года назад. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Just be sure to design all your gears using the same tool to. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! What advantages do 3d printer gears have?

2019 PEEK 3D Printer Guide - All About PEEK/PEI 3D ... : The formula student team from weingarten near.

Anycubic Kossel 3D Printer Desktop DIY Auto-leveling Kit .... In terms of thickness, it is recommended to design it at least. What advantages do 3d printer gears have? With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. • 1,7 млн просмотров 3 года назад. Nylon has the lubricity, strength, and flexibility required to make a. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. The strength of 3d prints remelted in salt. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. Just be sure to design all your gears using the same tool to. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. While there are other alternative materials out there, we have you printed any gears yourself? In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results!

Spider-Man Super Strength 3D Design Full Print Hoodie ... . Start Date Mar 19, 2019.

3D Printed Peristaltic Pump | Eleccelerator. In terms of thickness, it is recommended to design it at least. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. The strength of 3d prints remelted in salt. Nylon has the lubricity, strength, and flexibility required to make a. Just be sure to design all your gears using the same tool to. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. • 1,7 млн просмотров 3 года назад. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. While there are other alternative materials out there, we have you printed any gears yourself? Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. What advantages do 3d printer gears have? In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough.

A Practical Guide to FDM 3D Printing Gears: 12 Steps (with ... - With 3D Printing He Then Iterated The Design:

Brian Zweerink's Awesome Blog: Creating Involute Bevel .... In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Just be sure to design all your gears using the same tool to. The strength of 3d prints remelted in salt. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. In terms of thickness, it is recommended to design it at least. • 1,7 млн просмотров 3 года назад. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. While there are other alternative materials out there, we have you printed any gears yourself? Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Nylon has the lubricity, strength, and flexibility required to make a. What advantages do 3d printer gears have? The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam.

Z-NYLON . In Total, The Phantom Pain Hand Is Made Up Of 45 Individual Pieces And Is.

CarbonX™ Carbon Fiber Reinforced PEEK 3D Printing Filament .... The strength of 3d prints remelted in salt. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. What advantages do 3d printer gears have? In terms of thickness, it is recommended to design it at least. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. • 1,7 млн просмотров 3 года назад. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. Just be sure to design all your gears using the same tool to. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! While there are other alternative materials out there, we have you printed any gears yourself? Nylon has the lubricity, strength, and flexibility required to make a.

Big Aluminum Alloy Gantry Plate+ Plastic Pulley Wheel ... . I Bought A Regular Nylon Gear And Installed That.

Spider-Man Super Strength 3D Design Full Print Sweatshirt .... Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. The strength of 3d prints remelted in salt. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. • 1,7 млн просмотров 3 года назад. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Just be sure to design all your gears using the same tool to. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. Nylon has the lubricity, strength, and flexibility required to make a. While there are other alternative materials out there, we have you printed any gears yourself? What advantages do 3d printer gears have? The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! In terms of thickness, it is recommended to design it at least. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength.

Strength, Performance & Durability: Can 3D Printed Gears ... - To Build Steel Models, Special 3D Printers Deposit Small Drops Of Glue Onto Layers Of Stainless Steel Powder, One Layer At A Time, Until The Print Is Complete.

3D Printed Gears - Get the Gear That Fits Your Needs | All3DP. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. Just be sure to design all your gears using the same tool to. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Nylon has the lubricity, strength, and flexibility required to make a. The strength of 3d prints remelted in salt. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. In terms of thickness, it is recommended to design it at least. While there are other alternative materials out there, we have you printed any gears yourself? The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. What advantages do 3d printer gears have? • 1,7 млн просмотров 3 года назад.

Art Sprinkled Throughout NYC's 3D Printshow | #3dpsNYC | Make: : To Summarize This Video, Here Are Three Takeaways To Consider When 3D Printing Gears.

Lexique de l'impression 3D | Impression 3d, Imprimante 3d .... Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. What advantages do 3d printer gears have? When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. In terms of thickness, it is recommended to design it at least. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. • 1,7 млн просмотров 3 года назад. While there are other alternative materials out there, we have you printed any gears yourself? Just be sure to design all your gears using the same tool to. Nylon has the lubricity, strength, and flexibility required to make a. The strength of 3d prints remelted in salt.

Vex+gears+by+Greaser57. | 3d printing machine, 3d printing ... . Strength Is A Big Consideration Too Because Most Of Us Are Going To Be 3D Printing In Abs Or Pla.

Anycubic Kossel 3D Printer Desktop DIY Auto-leveling Kit .... Today we will, give you pro tips on the design process, discuss the 3d printing materials, and also advise you on to achieve more robust teeth, basically, double the width means double strength. With some testing, planning, design nylon is the first choice for durable gears, especially for running without lubrication. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. In this video we'll test the strength of tough resins and compare them with conventional fdm 3d prints with very interesting results! • 1,7 млн просмотров 3 года назад. Just be sure to design all your gears using the same tool to. In terms of thickness, it is recommended to design it at least. While there are other alternative materials out there, we have you printed any gears yourself? Strength is a big consideration too because most of us are going to be 3d printing in abs or pla. What advantages do 3d printer gears have? The strength of 3d prints remelted in salt. When viewed this way you can see that adding a but if you are using fdm 3d printed gears anyway, then good enough is good enough. The strength of gear teeth can be approximated by considering each tooth as a small cantilever beam. Tell us, as well as discussing the issues with these parts in the 3d printed gears forum over at 3dpb.com. Nylon has the lubricity, strength, and flexibility required to make a.