3D Printed Gears Gear Ratio. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. The gear template generator is able to print gears that span many pages. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. Tiny teeth are weaker and more difficult to print accurately. A ratio of 60/15 equates to a gear ratio of 4. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. Simple gearbox made with 3d printer and few hardware parts. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. By using both meshing and axes links you. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio.

3D Printed Gears Gear Ratio : Synchro Gearbox Designed In Pro/Engineer Using Skeleton Model, Gear Ratio Can Be Controlled Via Excel.

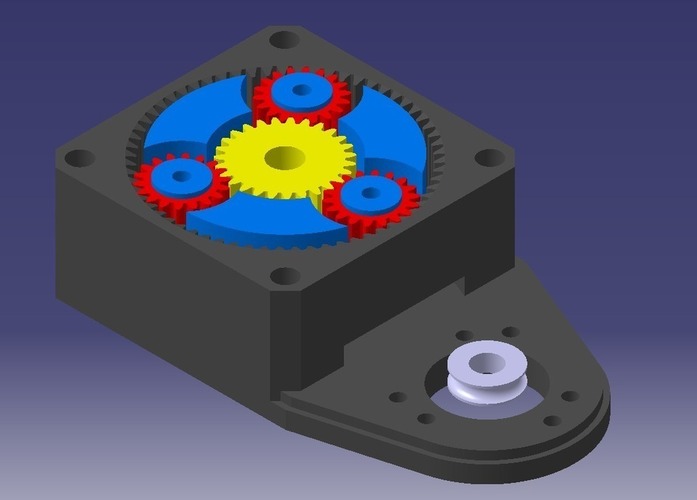

3D Printed Extreme Reduction Gearing Device Offers .... You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Simple gearbox made with 3d printer and few hardware parts. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. A ratio of 60/15 equates to a gear ratio of 4. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. By using both meshing and axes links you. The gear template generator is able to print gears that span many pages. Tiny teeth are weaker and more difficult to print accurately.

The combo of motor steps per rev, gear reduction ratio, belt pitch, and pulley teeth determine the full step imperfect gears will lead to periodic print defects.

Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. They can maximize power and efficiency and are based on simple mathematics. Gears can be animated with various speed to. The gear template generator is able to print gears that span many pages. With a crank and planetary gears built into the first gear or ring, it works to drive the next ring, which moves in the opposite direction. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Stepperonline mounting bracket for nema 17 stepper motor (economy geared stepper) hobby cnc/3d… this high precision nema 17 stepper motor has an integrated planetary gearbox with a 5.18:1 gear ratio, the resolution reach 0.35 deg. A ratio of 60/15 equates to a gear ratio of 4. 3d printed strain wave gear. Gear generator is a tool for creating involute spur gears and download them in dxf or svg format. Gear terminology this is one of the easiest guides on gears. When a gear is changed, different ring gears. The gear generator is the best online tool if you really don't have time or just don't want modeling, the website also offers an animation so you can see the gear working in real time rendering so you can stop it if you want or increase the rpm as you wish In machine design one often needs to incorporate a power transmission between an energy for basic analysis of gear ratios we initially neglect frictional losses, and then incorporate their effect separately. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. As a general rule, when dealing with two gears, if the drive gear (the one directly receiving rotational force from the engine, motor, etc.) is bigger than the driven gear, the latter. Helical meshing gears and 3d printing! An epicyclic gear train (also known as planetary gear) consists of two gears mounted so that the center of one gear revolves around the center of the other. By using both meshing and axes links you. 3d printed plastic gears for prototype construction. Gear ratio is ratio of the rotational speeds of two or more mating gears. In transmissions with multiple gear ratios—such as bicycles, motorcycles, and cars—the term gear as. Synchro gearbox designed in pro/engineer using skeleton model, gear ratio can be controlled via excel. In mechanical engineering, a gear ratio is a direct measure of the ratio of the rotational speeds of two or more interlocking gears. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. Thingiverse is a universe of things. Smooth running 3d printed gear bearing 3d printed file www.thingiverse.com/thing:2457318 find more videos here: Gear ratios are a core science behind almost every machine in the modern era. When two gears mesh, if one gear is bigger than the other, a mechanical advantage is produced, with the rotational speeds, and the torques, of the two gears differing in proportion to their diameters. The term gear ratio is used to calculate speed and torque of output gear when torque is applied to the input gear.

Nema 23 Stepper Motor Bipolar L56mm with Gear Ratio 15:1 ... - Easelink, A Company From Graz, Has Developed Matrix Charging, A Charging System That Automatically Connects The Bottoms Of Electric Cars With The Power Supply When They Are Parked.

4 lead Nema 16 Gear Stepper Motor Bipolar Gear Ratio 14:1 .... The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. Tiny teeth are weaker and more difficult to print accurately. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: By using both meshing and axes links you. A ratio of 60/15 equates to a gear ratio of 4. The gear template generator is able to print gears that span many pages. Simple gearbox made with 3d printer and few hardware parts. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction.

3D Printed Bevel Gears (MVMT 25): 11 Steps (with Pictures) , Synchro Gearbox Designed In Pro/Engineer Using Skeleton Model, Gear Ratio Can Be Controlled Via Excel.

Download free 3D printing models Bevel Gear Toy Set 17/51T .... The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. The gear template generator is able to print gears that span many pages. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Simple gearbox made with 3d printer and few hardware parts. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction.

1pcs NEMA17 compact planetary motor with MK8 extruder gear ... . Synchro gearbox designed in pro/engineer using skeleton model, gear ratio can be controlled via excel.

Compact planetary gearbox for the NEMA17 stepper motor .... There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Tiny teeth are weaker and more difficult to print accurately. Simple gearbox made with 3d printer and few hardware parts. A ratio of 60/15 equates to a gear ratio of 4. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: The gear template generator is able to print gears that span many pages. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. By using both meshing and axes links you. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction.

Tiny planetary gears set 3D-printed on a Makerbot ... , Gear Terminology This Is One Of The Easiest Guides On Gears.

From 3D printed gears to functional mechanism. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. Simple gearbox made with 3d printer and few hardware parts. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. By using both meshing and axes links you. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. A ratio of 60/15 equates to a gear ratio of 4. The gear template generator is able to print gears that span many pages. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Tiny teeth are weaker and more difficult to print accurately.

3D Printing | 0x7D.com , In Addition It Let You Compose Full Gear Layouts With Connetcted Gears To Design Multiple Gears System With Control Of The Input/Output Ratio And Rotation Speed.

Customize Your Ratios With A 3D-Printed Gearbox | Hackaday. Tiny teeth are weaker and more difficult to print accurately. By using both meshing and axes links you. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Simple gearbox made with 3d printer and few hardware parts. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. The gear template generator is able to print gears that span many pages. A ratio of 60/15 equates to a gear ratio of 4. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction.

3D Printing | 0x7D.com , With A Crank And Planetary Gears Built Into The First Gear Or Ring, It Works To Drive The Next Ring, Which Moves In The Opposite Direction.

Inside of 3D printed cyclo-reducer (gear ratio 1:11) - YouTube. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: A ratio of 60/15 equates to a gear ratio of 4. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. Simple gearbox made with 3d printer and few hardware parts. The gear template generator is able to print gears that span many pages. Tiny teeth are weaker and more difficult to print accurately. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. By using both meshing and axes links you. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion.

3D Printing | 0x7D.com . The Reason That You See Different Gearing Ratios Can Not Only Be Explained By Differences In The Extruder Gear/Hobbed Bolt Diameter Differences, But Also In Stepper Torque Values.

Nema17 42BYG Gear Ratio 18:1 Stepper Motor 1.3A 7NM .... The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. Tiny teeth are weaker and more difficult to print accurately. The gear template generator is able to print gears that span many pages. Simple gearbox made with 3d printer and few hardware parts. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. By using both meshing and axes links you. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. A ratio of 60/15 equates to a gear ratio of 4. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism.

RepRap 3D Printer Extruder Gear Stepper Motor 42 planetary ... - An Epicyclic Gear Train (Also Known As Planetary Gear) Consists Of Two Gears Mounted So That The Center Of One Gear Revolves Around The Center Of The Other.

Gearbox development using 3D printing | Ultrascale Products. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. Tiny teeth are weaker and more difficult to print accurately. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. The gear template generator is able to print gears that span many pages. A ratio of 60/15 equates to a gear ratio of 4. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. Simple gearbox made with 3d printer and few hardware parts. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. By using both meshing and axes links you. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio.

3D Printed Gearhead iPhone 5/6 Dock, Spiral Bevel Gear 51T ... , In Mechanical Engineering, A Gear Ratio Is A Direct Measure Of The Ratio Of The Rotational Speeds Of Two Or More Interlocking Gears.

Gear ratio 27:1 Planetary Gearbox stepper motor Nema 17 .... There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Tiny teeth are weaker and more difficult to print accurately. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. A ratio of 60/15 equates to a gear ratio of 4. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. Simple gearbox made with 3d printer and few hardware parts. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. By using both meshing and axes links you. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. The gear template generator is able to print gears that span many pages.

Planetary Gearbox Ratio 19:1 Nema 17 Stepper Motor ... - The Gear Generator Is The Best Online Tool If You Really Don't Have Time Or Just Don't Want Modeling, The Website Also Offers An Animation So You Can See The Gear Working In Real Time Rendering So You Can Stop It If You Want Or Increase The Rpm As You Wish

Free 3d printer files Bevel Gear Toy Set 17/51T or 3:1 .... More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. Tiny teeth are weaker and more difficult to print accurately. The reason that you see different gearing ratios can not only be explained by differences in the extruder gear/hobbed bolt diameter differences, but also in stepper torque values. But adding more teeth requires that each tooth get smaller to fit on the same diameter of gear. From plastic gears to metal gears, transform your 3d printed gears in a real functional mechanism. By using both meshing and axes links you. More teeth per gear increases the contact ratio (average number of teeth in contact at any time) and provides smoother rotary motion. The gear template generator is able to print gears that span many pages. There are four gears in the train, each with a 2:1 reduction, giving a 16:1 overall ratio. Gear reductions should be limited so that they do not minimize overall print speed or cause problems with retraction. A ratio of 60/15 equates to a gear ratio of 4. Printed plastic gears are a cheap, quick, and customizable motion transfer solution compared to alternative ways to make gears. Put a motor on the small gear's shaft, and the small gear turns 4 times before it feeds the 60 teeth needed to turn the big gear once. Simple gearbox made with 3d printer and few hardware parts. You will just have to create your great gear design as mentioned in our previous article on laser cutted gears, the angular ratio for gears is the following: