3D Print Layer Height. Editorial content, on principle, can not be bought or influenced. Keep reading to find out more! All3dp is an editorially independent publication. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. In the worth cas the plastic can expand/react/change state inside the hotend. This layer height provides a balance of speed, resolution and printing success. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Most 3d printers on the market utilize. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. The layer height of your 3d printed objects are important for quality, speed and even strength. 3d printing layer height is a simple setting. Depending on your extruder, it can also damage the filament preventing it to. This little factor has a lot to do not only with print speed, but also detail. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time.

3D Print Layer Height , Layer Thickness Not Only Affects The Speed (Printing Time), But Aslo The Quality Of Each Print.

Layer Height, Speed, and Quality on the Ember 3D Printer. The layer height of your 3d printed objects are important for quality, speed and even strength. All3dp is an editorially independent publication. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Most 3d printers on the market utilize. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. This little factor has a lot to do not only with print speed, but also detail. Editorial content, on principle, can not be bought or influenced. In the worth cas the plastic can expand/react/change state inside the hotend. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. 3d printing layer height is a simple setting. This layer height provides a balance of speed, resolution and printing success. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Depending on your extruder, it can also damage the filament preventing it to. Keep reading to find out more!

The balance between nozzle diameter and layer height comes down to both personal preference and project requirements.

Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. Is the height of layers on top of each other that are measured in the thickness of mm. Say it 5 times fast! Decreasing this value increases the number of layers that your model will contain, and that allows for more detail to be achieved. Polyjet 3d printing works similarly to inkjet printing, but instead of jetting drops of ink onto paper, the 3d printer jets layers of. 3d printing layer height and its effect on part strenght and print speed. Layer thickness not only affects the speed (printing time), but aslo the quality of each print. When you print one layer of plastic on top of another. Does layer height effect the sturdiness of a print? Past 0.2mm, the max stress remains fairly constant around 36 mpa (we confirmed this conclusion with an extra test at. Layer height influences the strength of a printed part when it becomes thin. However, a part printed at 100 microns on an fdm or sls. Narrower extrusion widths increase the number of perimeters that must be printed to produce a. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Layer height is the height of each layer that is extruded by the printer. Higher layer heights are quicker to print, but at the cost of strength and aesthetics of the print model. That's about the diameter of the extruded plastic that emerges from your extruder, and, theoretically,.4 mm is the highest layer height you can print with this nozzle. When printing on glass, this will give a very smooth bottom surface. This little factor has a lot to do not only with print speed, but also detail. But, there is a catch. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. However, for the final part to be strong however, these small nozzles also create some limitations for what layer heights can be used. A printed part at 0.1mm shows a max stress of only 29mpa, as opposed to 35mpa for 0.2mm (21% increase). Editorial content, on principle, can not be bought or influenced. That said, for larger prints, you really won't want to lower the layer height too much. The balance between nozzle diameter and layer height comes down to both personal preference and project requirements. Thinner layers have more extrusions of material per part, but the thicker layers have fewer, thicker extrusions. Keep reading to find out more! The aim is to adjust the nozzle height the first layer calibration being set incorrectly can lead to various issues. Layer height in 3d printing doesn't substantially affect part strength. All3dp is an editorially independent publication.

David Riley Model Making - 3D Printing - But Why Does This Increase The Print Quality?

Local 3D Printing Service Near You | makexyz.com. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. This little factor has a lot to do not only with print speed, but also detail. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. The layer height of your 3d printed objects are important for quality, speed and even strength. 3d printing layer height is a simple setting. Editorial content, on principle, can not be bought or influenced. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. All3dp is an editorially independent publication. This layer height provides a balance of speed, resolution and printing success. In the worth cas the plastic can expand/react/change state inside the hotend. Most 3d printers on the market utilize. Keep reading to find out more! In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. Depending on your extruder, it can also damage the filament preventing it to. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance.

3D Printing - Layer Height Under The Microscope | 3D ... . What Is Layer Height In 3D Printing?

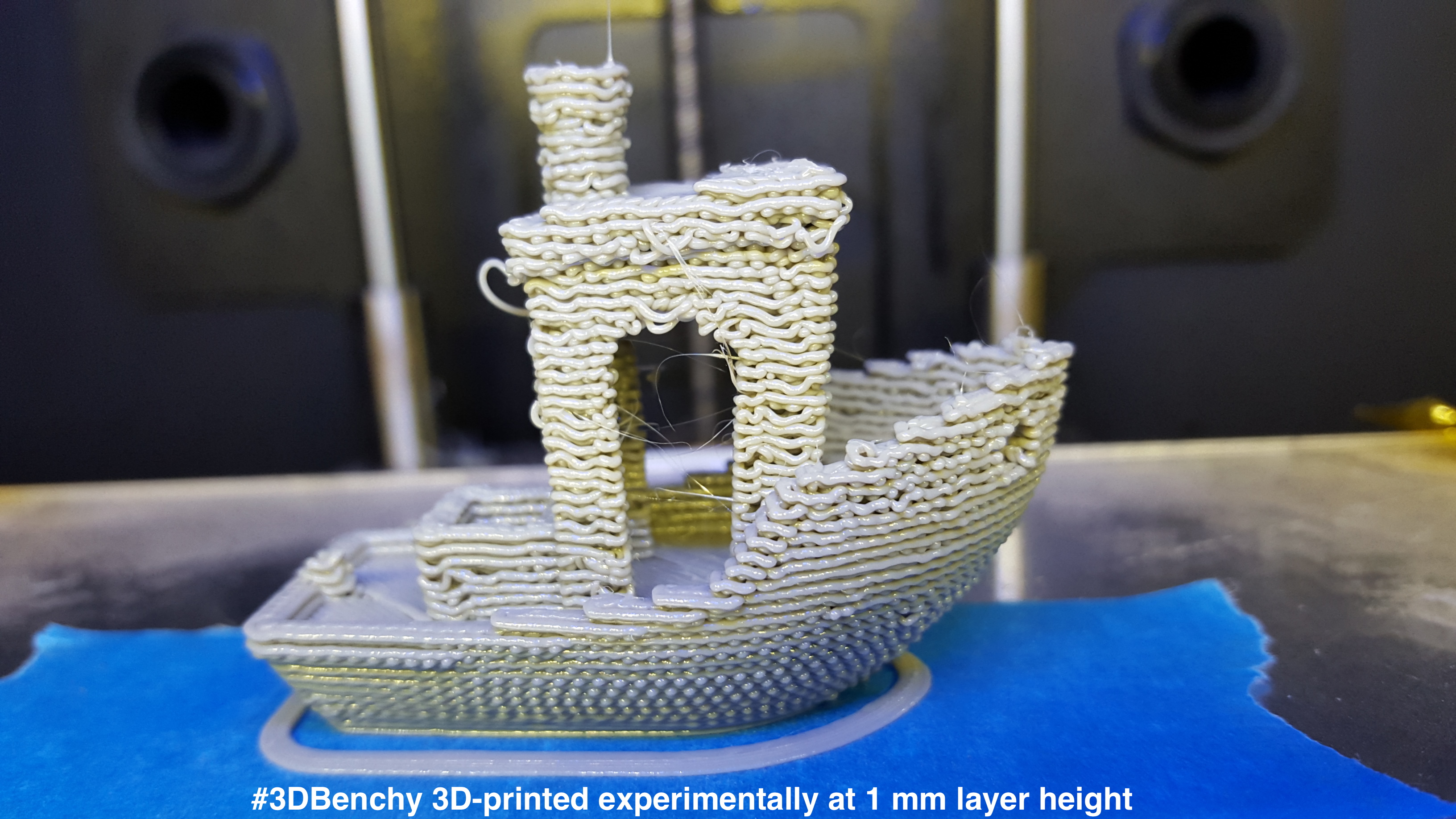

3D printer improvements: Extremely fat extrusion with a 1 .... 3d printing layer height is a simple setting. All3dp is an editorially independent publication. In the worth cas the plastic can expand/react/change state inside the hotend. Depending on your extruder, it can also damage the filament preventing it to. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. The layer height of your 3d printed objects are important for quality, speed and even strength. This layer height provides a balance of speed, resolution and printing success. Keep reading to find out more! In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. Editorial content, on principle, can not be bought or influenced.

Prusa Mk2 Benchies @ 200/100/050 Microns - 3D Print Direct - One thing to note is layer height is not the same as resolution.

Layer Height, Speed, and Quality on the Ember 3D Printer. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. All3dp is an editorially independent publication. 3d printing layer height is a simple setting. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. In the worth cas the plastic can expand/react/change state inside the hotend. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Keep reading to find out more! Depending on your extruder, it can also damage the filament preventing it to. This layer height provides a balance of speed, resolution and printing success. Most 3d printers on the market utilize. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Editorial content, on principle, can not be bought or influenced. The layer height of your 3d printed objects are important for quality, speed and even strength. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. This little factor has a lot to do not only with print speed, but also detail.

Reprap development and further adventures in DIY 3D ... , Simply Put, It's The Thickness Of Each Line Of Extruded Material That Makes Up Each Layer Of Your Print.

Troubleshooting: Stop Your 3D Prints from Warping .... The layer height of your 3d printed objects are important for quality, speed and even strength. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. This little factor has a lot to do not only with print speed, but also detail. 3d printing layer height is a simple setting. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. In the worth cas the plastic can expand/react/change state inside the hotend. Editorial content, on principle, can not be bought or influenced. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Most 3d printers on the market utilize. All3dp is an editorially independent publication. This layer height provides a balance of speed, resolution and printing success. Depending on your extruder, it can also damage the filament preventing it to. Keep reading to find out more!

Prusa Mk2 Benchies @ 200/100/050 Microns - 3D Print Direct . Chep Did A Video On Magic Numbers, Which Are The Layer Heights That Align Evenly With The Number Of Steps On Your Motor.

What 3D Printer Nozzle Size Should I Use? - The Pros and .... The layer height of your 3d printed objects are important for quality, speed and even strength. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This little factor has a lot to do not only with print speed, but also detail. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. In the worth cas the plastic can expand/react/change state inside the hotend. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. Editorial content, on principle, can not be bought or influenced. Keep reading to find out more! Most 3d printers on the market utilize. All3dp is an editorially independent publication. Depending on your extruder, it can also damage the filament preventing it to. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. This layer height provides a balance of speed, resolution and printing success. 3d printing layer height is a simple setting.

Reprap development and further adventures in DIY 3D ... , A Printed Part At 0.1Mm Shows A Max Stress Of Only 29Mpa, As Opposed To 35Mpa For 0.2Mm (21% Increase).

Printing with the Makerbot Replicator 2. The layer height of your 3d printed objects are important for quality, speed and even strength. Keep reading to find out more! Editorial content, on principle, can not be bought or influenced. In the worth cas the plastic can expand/react/change state inside the hotend. Most 3d printers on the market utilize. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. 3d printing layer height is a simple setting. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. Depending on your extruder, it can also damage the filament preventing it to. This layer height provides a balance of speed, resolution and printing success. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. All3dp is an editorially independent publication. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. This little factor has a lot to do not only with print speed, but also detail.

3D Printing: Layer Height | Spiritdude's Public Notebook . It's Best To Experiment With The Parameters Of Your Print, As Long As You Understand The Relationship Between 3D Printer Nozzle Size Vs Layer Height You'll Be On Track.

How Do Layer Height & Infill Settings Impact 3D Print .... This layer height provides a balance of speed, resolution and printing success. Editorial content, on principle, can not be bought or influenced. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. The layer height of your 3d printed objects are important for quality, speed and even strength. Depending on your extruder, it can also damage the filament preventing it to. This little factor has a lot to do not only with print speed, but also detail. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. Keep reading to find out more! Most 3d printers on the market utilize. 3d printing layer height is a simple setting. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. In the worth cas the plastic can expand/react/change state inside the hotend. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. All3dp is an editorially independent publication.

MakerBot Replicator 2 - PLA blue frogs - Layer thickness ... , A Printed Part At 0.1Mm Shows A Max Stress Of Only 29Mpa, As Opposed To 35Mpa For 0.2Mm (21% Increase).

What is Layer Height/Layer Resolution in 3D Printing? - RP .... This layer height provides a balance of speed, resolution and printing success. 3d printing layer height is a simple setting. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Depending on your extruder, it can also damage the filament preventing it to. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. In the worth cas the plastic can expand/react/change state inside the hotend. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. This little factor has a lot to do not only with print speed, but also detail. Keep reading to find out more! Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. The layer height of your 3d printed objects are important for quality, speed and even strength. Most 3d printers on the market utilize. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time.

Tech Talk Thursday: Intro to 3D Printing - Enabling The Future : Im Trying To Print A Cylinder With First Layers At 0.1, Middle With 0.2 And Top With 0.1 Again.

What 3D Printer Nozzle Size Should I Use? - The Pros and .... This layer height provides a balance of speed, resolution and printing success. The layer height of your 3d printed objects are important for quality, speed and even strength. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. This little factor has a lot to do not only with print speed, but also detail. Keep reading to find out more! Depending on your extruder, it can also damage the filament preventing it to. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Most 3d printers on the market utilize. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. In the worth cas the plastic can expand/react/change state inside the hotend. All3dp is an editorially independent publication. 3d printing layer height is a simple setting. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. Editorial content, on principle, can not be bought or influenced.

CREAT3D handy 3D printing tips - what do microns really mean? , In Today's Video, We Cover Tuning In Your Layer Height, Another Crucial Part Of Printing Parts Perfectly Every Time.

When to Use Different Layer Heights. Keep reading to find out more! On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Editorial content, on principle, can not be bought or influenced. In today's video, we cover tuning in your layer height, another crucial part of printing parts perfectly every time. All3dp is an editorially independent publication. Printing with a layer height too low might cause the plastic to be pushed back into the nozzle and the extruder will struggle to push the filament. This layer height provides a balance of speed, resolution and printing success. This little factor has a lot to do not only with print speed, but also detail. Layer height will have an impact on the vertical resolution of the part, affecting its smoothness. In the worth cas the plastic can expand/react/change state inside the hotend. 3d printing layer height is a simple setting. Your layer height should be between 25% and 75% of your nozzle diameter or you might run into printing issues. The layer height of your 3d printed objects are important for quality, speed and even strength. Most 3d printers on the market utilize. Depending on your extruder, it can also damage the filament preventing it to.