3D Print Extrusion Speed. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. High print speeds could be the reason why you experience under intrusion with your 3d printer. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. Under extrusion can significantly interfere with the success of your 3d project. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. 3d printing speed measures the amount of manufactured material over a given time period (. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Try decreasing your print speed by 20 mm/s and observe the result. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. Extrusion width defines how wide the lines of extruded material are. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there.

3D Print Extrusion Speed : If Your Print Speed Is Too High, Your Printer May Have Difficulty Extruding Enough Filament In A Shorter Amount Of Time.

A tour around the world of 3D-printing technologies .... In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. Extrusion width defines how wide the lines of extruded material are. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Try decreasing your print speed by 20 mm/s and observe the result. Under extrusion can significantly interfere with the success of your 3d project. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. The print speed calculator has been developed to help you choose the right setting based on our experimental values. 3d printing speed measures the amount of manufactured material over a given time period (. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. High print speeds could be the reason why you experience under intrusion with your 3d printer.

In this guide, i will attempt to give an introduction to the wide range of technologies in 3d printers, a comparison of the most common 3d pri…

The newly announced hse 3d printer can print at speeds up to 1m/s. Historically, extrusion 3d printing processes like fff have been painstakingly slow, taking hours to produce a relatively simple geometry and days to produce complex designs. This is caused by the lack of enough time for plastics to drip. I really have not found any value. Think of a situation where the extruder takes longer time to move from point a to point with low temperature alongside with higher speed, users may notice under extrusion. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. The new innovation was reported in the journal additive manufacturing. 3d printing inconsistent extrusion troubleshooting. 3d printing is a quickly expanding field, with the popularity and uses for 3d printers growing every day. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. During 3d printing, when the extruder moves to a different location, it must continue to stop or start extruding. By designing the entire machine for the performance needed to support our high speed extrusion printing process. I was wondering what a good speed is for printing with a reprap (prusa i2/mendel). Thinner layers have more extrusions of material per part, but the strands this type of infill prints relatively quickly because the printhead mostly travels in straight lines across the part. Most extruders produce a consistent extrusion line during operation. I have no idea if this speed could be increased more. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. When printing both the supports and model in petg, supports should ideally peel away by hand. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. The newly announced hse 3d printer can print at speeds up to 1m/s. Scheduled for release in q4 2018, the hse 3d printer will cost $55,000. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. 1.00 flow, extrusion speed at 45 mm/s. The speed a printhead can be moved, the force pushing the printing material through the nozzle, and the rate the material can be melted to make it flow. I've been unsuccessfully trying to print wood pla (hatchbox timberfill rosewood) on my prusa i3 mk2. The essentium high speed extrusion 3d printer. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Using fdm and sla 3d printers together. Take a look at the printer in action in the video below. The print speed is capable of keeping 3d printing stringing at bay.

How to Speed Up 3D Printing? . The Strength And The Speed Combined Makes.

MK8 Extruder Hot End kit 800-001-0477 - $5.50 : geeetech .... If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. High print speeds could be the reason why you experience under intrusion with your 3d printer. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. The print speed calculator has been developed to help you choose the right setting based on our experimental values. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. Under extrusion can significantly interfere with the success of your 3d project. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Try decreasing your print speed by 20 mm/s and observe the result. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. 3d printing speed measures the amount of manufactured material over a given time period (. Extrusion width defines how wide the lines of extruded material are.

Some Calibration Photographs - Help, Tips & Tricks ... - Layer Height In 3D Printing Doesn't Substantially Affect Part Strength.

3D Printer Retraction Speed - What Does It Mean? | All3DP. The print speed calculator has been developed to help you choose the right setting based on our experimental values. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. Extrusion width defines how wide the lines of extruded material are. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. Try decreasing your print speed by 20 mm/s and observe the result. 3d printing speed measures the amount of manufactured material over a given time period (.

fluid dynamics - In 3D printing does the Bernouilli ... . When printing both the supports and model in petg, supports should ideally peel away by hand.

3D Print Speed: How to find the optimal speed for reliable .... If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. Under extrusion can significantly interfere with the success of your 3d project. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. Try decreasing your print speed by 20 mm/s and observe the result. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. High print speeds could be the reason why you experience under intrusion with your 3d printer. 3d printing speed measures the amount of manufactured material over a given time period (. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. Extrusion width defines how wide the lines of extruded material are. The print speed calculator has been developed to help you choose the right setting based on our experimental values.

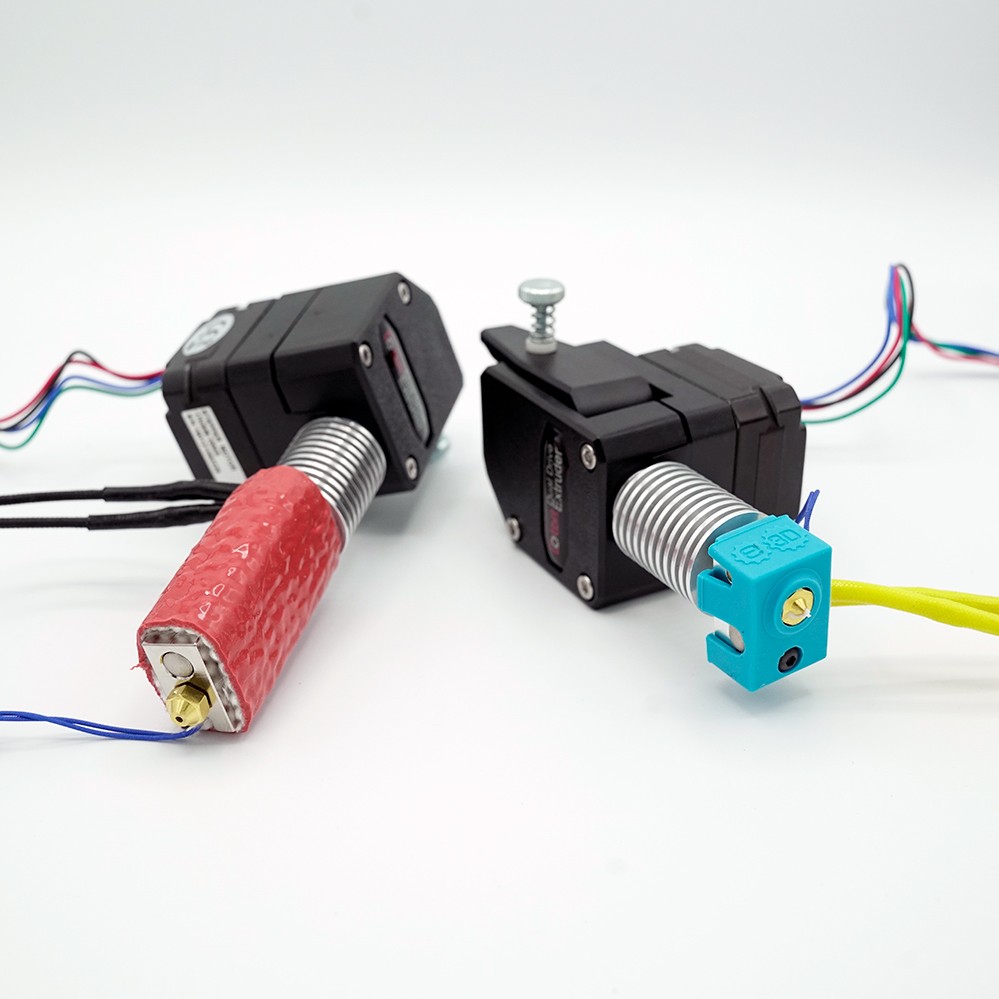

3D printer direct-drive extruder |Autodesk Online Gallery : This Combined With The 0.1Mm Extra Bed Distance Has Removed Much Of The Random Stringing (Which Is Caused By The Nozzle Going.

Direct Drive vs Bowden Extruder Guide and Calibration Tips. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Try decreasing your print speed by 20 mm/s and observe the result. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. 3d printing speed measures the amount of manufactured material over a given time period (. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. High print speeds could be the reason why you experience under intrusion with your 3d printer. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. Extrusion width defines how wide the lines of extruded material are. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Under extrusion can significantly interfere with the success of your 3d project. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce.

Important Things to Know About Dual Extrusion in 3D Printers : 3D Printing Stack Exchange Is A Question And Answer Site For 3D Printing Enthusiasts.

Fraunhofer IWU develops Screw Extrusion Additive .... High print speeds could be the reason why you experience under intrusion with your 3d printer. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Under extrusion can significantly interfere with the success of your 3d project. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. Try decreasing your print speed by 20 mm/s and observe the result. 3d printing speed measures the amount of manufactured material over a given time period (. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Extrusion width defines how wide the lines of extruded material are. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there.

New AXIOM Dual Extruder 3D Printer - Airwolf 3D Printers : Essentium Hse Technical Specifications And Pricing.

A tour around the world of 3D-printing technologies .... Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. High print speeds could be the reason why you experience under intrusion with your 3d printer. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. 3d printing speed measures the amount of manufactured material over a given time period (. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. Try decreasing your print speed by 20 mm/s and observe the result. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Under extrusion can significantly interfere with the success of your 3d project. Extrusion width defines how wide the lines of extruded material are. The print speed calculator has been developed to help you choose the right setting based on our experimental values. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius.

3D Matter Tests Color, Speed, & More - 3D Printing Industry - Higher Values Require More Pressure To Squeeze The Molten Filament Out Of I Investigated How Different Extrusion Widths Impact The Quality And The Strength Of Our 3D Prints And Discovered That This Might Be A Way To Produce.

fluid dynamics - In 3D printing does the Bernouilli .... 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. Extrusion width defines how wide the lines of extruded material are. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. Under extrusion can significantly interfere with the success of your 3d project. 3d printing speed measures the amount of manufactured material over a given time period (. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. High print speeds could be the reason why you experience under intrusion with your 3d printer. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Try decreasing your print speed by 20 mm/s and observe the result. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there.

The Original Prusa 3D Printers - Knowledge base ... . 3D Printing Speed Measures The Amount Of Manufactured Material Over A Given Time Period (.

What is the influence of color, printing speed, extrusion .... The print speed calculator has been developed to help you choose the right setting based on our experimental values. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. 3d printing speed measures the amount of manufactured material over a given time period (. High print speeds could be the reason why you experience under intrusion with your 3d printer. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. Extrusion width defines how wide the lines of extruded material are. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. Try decreasing your print speed by 20 mm/s and observe the result. Under extrusion can significantly interfere with the success of your 3d project. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly.

Fast desktop-scale extrusion 3D printing - YouTube , In Simplify3D You Control Print Speed As Mm/Minute And In Cura, It's Mm/S, So There's A 1:60 Difference There.

A tour around the world of 3D-printing technologies .... Extrusion width defines how wide the lines of extruded material are. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. Try decreasing your print speed by 20 mm/s and observe the result. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. High print speeds could be the reason why you experience under intrusion with your 3d printer. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. 3d printing speed measures the amount of manufactured material over a given time period (. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. Under extrusion can significantly interfere with the success of your 3d project. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time. The print speed calculator has been developed to help you choose the right setting based on our experimental values.

What is the influence of color, printing speed, extrusion ... . Then Each Time The Extruder Is Turned On Again, It Will Be A Noticeable Change, This Is Often Referred As A Spot Or Scar.

Is Higher Extrusion Speed Key to Improving FDM Part .... Try decreasing your print speed by 20 mm/s and observe the result. Under extrusion can significantly interfere with the success of your 3d project. 3d printing speed measures the amount of manufactured material over a given time period (. This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. High print speeds could be the reason why you experience under intrusion with your 3d printer. In the extrusion process, you will have to make the recommended printing temperature for pla is about 220 degrees celsius. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. ), where the unit of time is measured in hours, and the unit of manufactured material is typically measured in units of either kg, mm or cm3, depending on the type of additive manufacturing technique. Is there a way to read the value of the extrusion speed, essentially the f term from the gcode commands, and change my retraction routine accordingly. Extrusion width defines how wide the lines of extruded material are. The print speed calculator has been developed to help you choose the right setting based on our experimental values. In simplify3d you control print speed as mm/minute and in cura, it's mm/s, so there's a 1:60 difference there. If the nozzle width is a constant and we assume that the path is always the width of the nozzle width, then the extrusion volume needed to fill the path depends on the length of the trace and the. Higher values require more pressure to squeeze the molten filament out of i investigated how different extrusion widths impact the quality and the strength of our 3d prints and discovered that this might be a way to produce. If your print speed is too high, your printer may have difficulty extruding enough filament in a shorter amount of time.